Maanshan Kingrail Technology Co.,Ltd. |

|

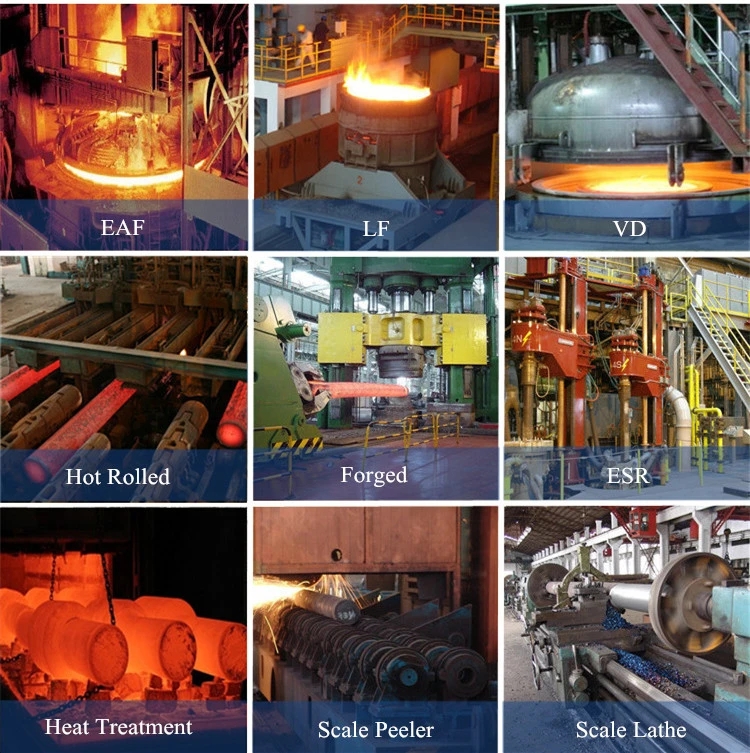

For 7.5kw AC Semi Trailer Axles Kingrail OEM ODM For Freight Wagon, Kingrail railway axle heat treatment system includes a cooling device, a normalizing device and a tempering device. The cooling device and the inlet of the normalizing device are connected through a roller table, and the outlet of the normalizing device and the inlet of the tempering device are connected through the roller table. The beneficial effect of the present invention is that the normalizing device is connected with the tempering device to realize continuous production of different process routes, and the cooling device is provided to cool the axle, and can improve the cooling speed and production efficiency.

A steel material for an axle and a processing method thereof belong to the field of metal smelting and processing. Contains the following ingredients: 0.46~0.58wt% of C, 0.17~0.40wt% of Si, 0.75~1.00wt% of Mn, ≤0.015wt% of P, ≤0.010wt% of S, 0.18~0.25wt% of Ni, 0.20 to 0.27 wt% of Cr, ≦0.15 wt% of Cu, ≦0.10 wt% of Mo, 0.02 to 0.08 wt% of V, 0.015 to 0.045 wt% of Al, etc., with the balance being Fe. The process flow of the present invention is: electric furnace smelting or converter smelting → LF furnace refining → RH or VD vacuum treatment → continuous casting → slow cooling or hot delivery → forging heating → hydraulic press forging billeting → forging billet heating → rolling → slow cooling →Normalizing and tempering. Therefore, the shaft material produced by KINGRAIL is dense and uniform.

Trailer Parts American Outboard Axle for Semi Trailer Axles 7.5kw AC Motor Drive Rear Axle

Kingrail Railway axle processing production line. To solve the problem that two kinds of axles can be produced at the same time, a railway axle processing production line, including the main line and the auxiliary line, the main line is arranged from left to right, the auxiliary line is arranged from right to left, and the main line is arranged in sequence from south to north Semi-finishing CNC lathe I, finishing CNC lathe I, CNC grinder I, and ordinary grinder I. The auxiliary lines are arranged from north to south with semi-finishing CNC lathe II, finishing CNC lathe II, CNC grinder II and ordinary Grinding machine II, the main line and the auxiliary line are equipped with a finished axle inspection area, and the axle inspection area is equipped with an axle flaw detector and an axle inspection area.

Trailer Parts American Outboard Axle for Semi Trailer Axles 7.5kw AC Motor Drive Rear Axle

Our Advantages of 7.5kw AC Semi Trailer Axles Kingrail OEM ODM For Freight Wagon :

1. We can supply various kinds of finished and semi-finished railway axle for railway rolling stocks.(Railway axle)

2. Accredited with AAR quality certificate, IRIS and Jinxi has maintained sound relations with Wabtec, GE, Bombardier, Alstom and Siemens multinational companies.

3. We can manufacture axles in accordance with EN 13261, AAR M-101, IRS 16/95, JIS E 4502, TB/T 2945, BS 5892, KS9220

4. Axle series applications:

Axle for railway passenger coach

Axle for railway freight wagon

Alex for locomotive

Alex for metro car

Alex for rail bus

5. Compertitive Price, and Fast Delivery Leadtime

If you are interested, please feel free to contact us. We will try our best to assist you and make you feel comfortable about your choice.