Gaoge-Tech Instrument Co., Ltd. |

|

Automatic Furniture Integrated Universal Testing Instrument 0.01-30s Can be Set

1.Product description:

This machine is a comprehensive testing machine for testing the

mechanical properties of furniture. Applicable to household, hotel,

hotel, restaurant and other occasions used in various tables,

chairs, cabinets, single-layer bed furniture, finished products,

other tables, chairs, cabinets, single-layer bed furniture Can

refer to the implementation. Tables, chairs, cabinets, cabinets,

single-layer bed strength and durability tests are tests that

simulate the strength or endurance of furniture under normal or

used misuse, subject to single-use or repetitive loads. Tables,

chairs and cabinets, cabinets stability test is to simulate the

ability of furniture to withstand the load (or no load) in daily

use, the ability to resist tilting.

2.Standards compliant:

| GB/T10357.1-2013 | Furniture mechanical properties test part 1:Table strength and durability |

| GB/T10357.2-2013 | Furniture mechanical properties test part 2:Chair stool stability |

| GB/T10357.3-2013 | Furniture mechanical properties test part 3:Chair stool strength and durability |

| GB/T10357.4-2013 | Furniture mechanical properties test part 4:Cabinet stability |

| GB/T10357.5-2013 | Furniture mechanical properties test part 5:Cabinet strength and durability |

| GB/T10357.6-2013 | Furniture mechanical properties test part 6:Single bed strength and durability |

| GB/T10357.7-2013 | Furniture mechanical properties test part 7:Table stability |

| Standard test methods and functional requirements. | |

3.Technical Parameters:

| Load capacity | 0-300kg can be set arbitrarily |

| Load weight accuracy | 1/100000 |

| Test accuracy | Static: ±0.1% |

| Dynamic force: ±2% | |

| Loading mode | cylinder servo proportional control loading, force value displacement is set arbitrarily |

| Displacement stroke | 0-300mm, 0-500mm, 0-800mm can be selected |

| Time for various actions | 0.01-30s can be set arbitrarily |

| Test speed | 5-30 times / minute can be arbitrarily set |

| Number of trials | It can be set arbitrarily from 0-999999 times |

| Power-off memory | It has the function of stop/stop power memory and breakpoint detection and shutdown. Stopping or powering down will automatically save the test results |

| Shutdown mode | stop the number of trials and alarm |

| Sensor | Imported brand sensor |

| The device has a fault self-diagnosis system for easy inspection and troubleshooting. | |

| The basic frame adopts the modular structure of high-strength aluminum metal frame. The bottom frame adopts three-dimensional structure and the structure is stable. The cross-sectional area of aluminum profile is not less than 100×100, the thinnest thickness is not less than 5mm thick aluminum alloy, and the edge of 6mm steel plate Reinforce. | |

| Base | high-strength industrial aluminum profile + national standard 45 steel, thickness ≥10mm, rubber surface 2mm, strong magnet fixed sample |

| Machine specifications | 6.8 m × 2.6 m × 2.4 m |

4.Software function:

4.1 The program screen can be selected from Simplified Chinese,

Traditional Chinese, English, and can be replaced at any time in

the program settings page.

4.2 The closed loop control of this unit is not less than 8

channels.

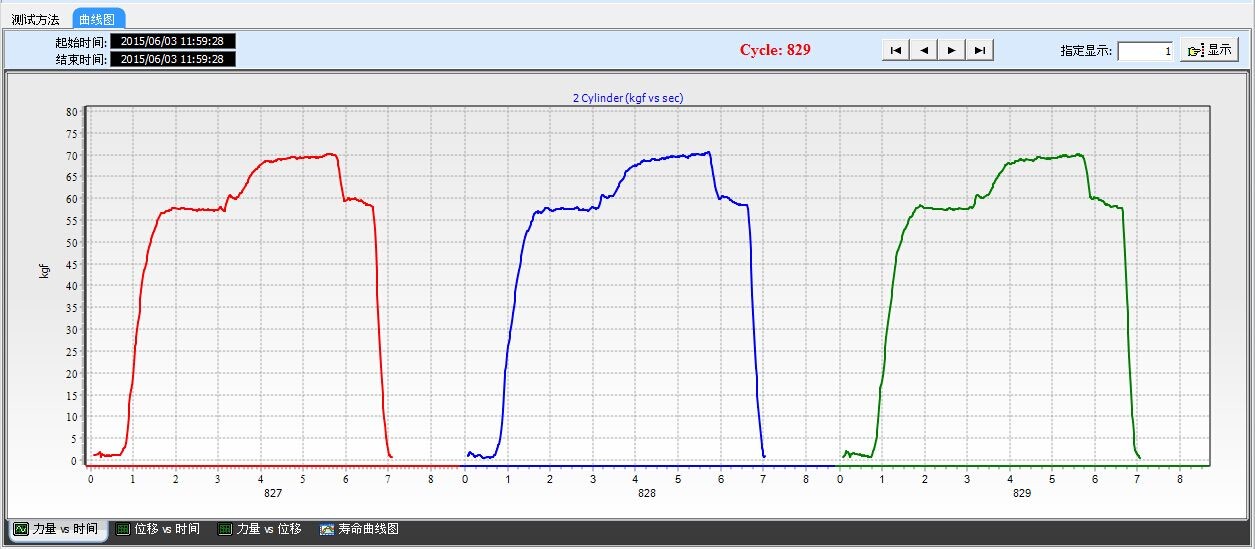

4.3 After the test is completed, the software can store each cycle

curve (power--displacement, force-time, displacement-time curve).

Different from other products of the same category, only the

maximum force curve can be stored, that is, the maximum force and

the minimum force value. frequency.

4.4 Each cylinder can be independently programmed with 100 steps,

and each channel can be tested in any combination.

Automatic power-off storage, power-on can continue the previous

test to continue to prompt function

4.5 Computer integrated control system, multi-channel data

acquisition, control multiple channels, can control multiple test

axes at the same time, can set the action of a certain cylinder or

motor separately, including single or multiple reciprocating tests,

can set two Two groups of coordinated actions, the same direction

and opposite direction test. Each channel is operated by the

reference synchronization time, which ensures the synchronization

of the action and data processing. Different channels are grouped

to control. If one channel of the sample is destroyed, the

associated channels in the same group will stop at the same time.

You can continue working. The interface is simple, full-featured,

high-speed response, and easy to operate. Accurate action and low

failure rate.

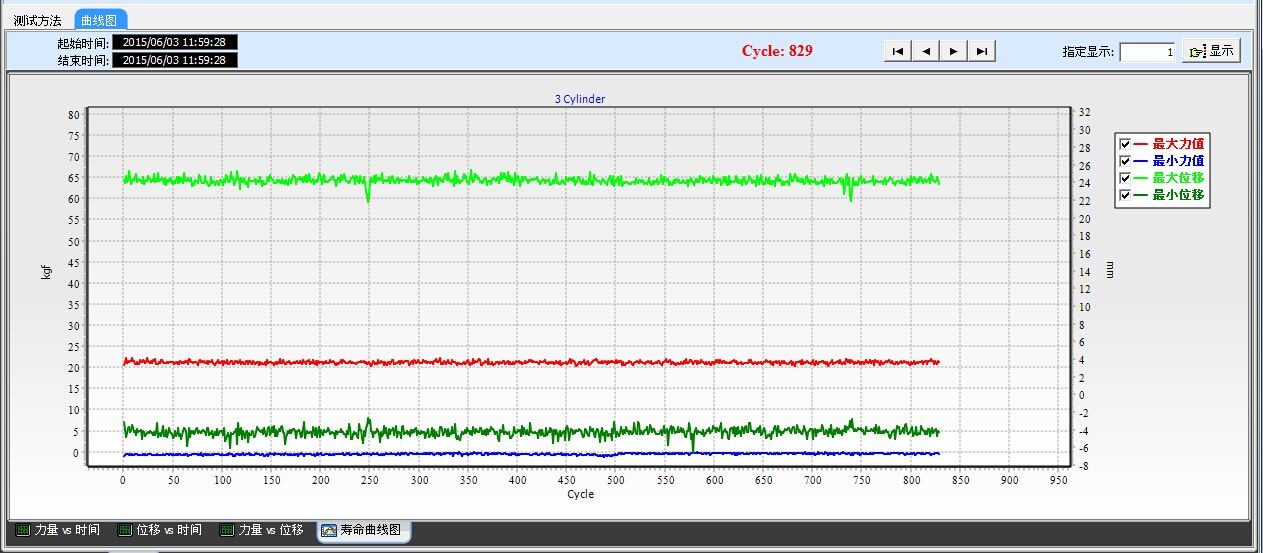

4.6 Can realize the control of force and displacement speed,

display displacement-time, force-time, force-displacement,

force-displacement maximum and minimum life curve (variation curve

of maximum force value and maximum displacement value of each

channel in each cycle) Wait. There is no need to manually adjust

the force value and displacement, and the displacement offset is

displayed every time to realize intelligent integrated control.

4.7 The unit of force value can be selected as kgf, to, lbf, kN, N.

4.8 The unit of the displacement value can be selected as mm, in.

4.9 Each force and displacement sensor can be divided into 10

segments or single segment correction.

4.10 Reports can be exported to Word, Excel, PDF files, saved and

exported, and printed with the printer.

4.11 The instrument adopts automatic ascending and descending

device, which can move left and right and move back and forth for

convenient injection.

4.12 Each cylinder can be set to run arbitrarily. The step function

includes selection of open loop and closed loop. Up to 100 run

steps can be programmed.

4.13 Record the curve of each cycle of each cylinder. When the test

is stopped, you can view the curve of any cycle.

4.14 The test curve data will be recorded in the database. When the

program does not run the test, the display curve data can be called

from the database.

4.15 Computer software automatic servo control, the display screen

observes all force values and offset data.

4.16 The multi-channel closed-loop control can be realized by special control software, and the fully automatic control and automatic measurement of the test can be completed.

5.Curve interface:

Power-time curve

Life curve

Corporate partners

Company Certification

Company profile

Service Process:

| Free Pre-Sales Consulting GAOGE-TECH offer 12 hours quick pre-sales response and free consulting. Any kind of technical support is available for users. We offer progressing solution design to all the users. |

| 20 Days Quick Delivery We have mass production and stock & ready item, for these items, we offer 20 days quick delivery time. For big machine and special requirement, we will trade you as the priority customer and to produce your cargo for the first time. |

| 1 Year Quality Guarantee GAOGE-TECH 1-year guarantee for our machine. And to become you are our long-term customer, we will prolong the quality guarantee period especially for you. |

| 12 hours Quick Feedback & After-Sales Service We will offer "Training Video", "Instruction Book", "Operation Manual" to you, which is easy to learn and operate. We will supply brochures for simple trouble-shootings of the machine, which will help you deal with the common problems happened to the machine. We will offer plenty of technical support online, just like detailed technical and installation instructions. For example, when you meet a maintenance problem, we will make a video with completed and detailed operation process according to the problem, it just seems that I am on the spot by your side to instruct you how to deal with the problem. |

| Quick Back-up Parts Available & Technical Assistance Our extensive inventory of spare parts means replacements get shipped to you as quickly as possible. Immediate technical assistance is only an email or phone call away. |

| Free Training Service We insist that our customers receive personal, hands-on training with every machine we sell. This training is free, and we will work with you for as long as it takes to ensure you feel comfortable operating your machine. We pride ourselves on our expertise and our ability to educate our customers in the installation, proper maintenance, and most efficient use of GAOGE-TECH machines. |

| Special Designing, Customized, OEM Order is accepted GAOGE-TECH is rather willing to help you to realize your special testing and requirement by our innovative ability. So please do not hesitate to contact us when you need special design or customized machine and OEM machines. |

Packaging & Shipping

1.Inside is covered with plastic film before we put them into the

plywood, which has good transparency, impact resistance, tasteless

and prevent moisture corrosion.

2.Outside is strong plywood and accord with export standards.

3.We can ship testing equipment according to customer request.