Gaoge-Tech Instrument Co., Ltd. |

|

Martin Wear Testing Instrument, Foot Wear Test With 6 Heads

1.Introduction:

The wear-resistant pilling tester can detect the abrasion

resistance and pilling performance of various structural fabrics.

The sample is subjected to a low-pressure continuous commutation

friction with a certain friction material.

The degree of wear and pilling can be compared with standard

parameters. The instrument uses a movable sample fastening

component to take out a certain friction sample at any time.

Without affecting other samples, not only the rapid and independent

detection of the sample, but also the accuracy of the synchronous

measurement of the friction is ensured, which is the approved

fastening method of BSEN ISO12947-1:1999. The instrument is

equipped with an electronic preset batch timer and a total counter,

sample holder and load device

(In accordance with international testing standards) models

available in 4, 6, and 8 heads.

2.The design standard

ISO 5470, DIN 53863/53865, BS 3424/5690, IWTO 40-88, BS EN 388/530,

IWSTM 112/196, ASTM 4966/4970 IS 12673, JIS L1096, SFS 4328, PR EN

ISO 12947-1, PR EN ISO 12945-2, SATRA TM31, ISO 20344

3.Technical parameters:

| The number of trials | 1~999999 |

| Cumulative count | 1~999999 |

| The number of test heads | 6 |

| The effective friction diameter of the grinding block | φ28.8mm |

| Relative movement speed of holder and grinding table | 50r/min |

| Clothing sample weight | 395g |

| The ornament sample weight | 594g |

| Power | AC220V, 250W |

4.Determination of the abrasion resistance of fabrics:

| The distance of the drive shaft from its central axis | (30.25 ± 0.25) mm |

| Ratio of external transmission speed to internal transmission speed | 16:15 |

| The maximum stroke of the pattern clamp guide in the longitudinal and lateral directions | (60.5±0.5)mm |

| Pressure hammer: mass | 2.5±0.5kg, diameter 120±10mm |

| Anti-friction sample set | load weight + guide shaft + friction head, the total weight should be 198 ± 2g |

| Sample clamp pin | diameter 7.950 (-0.013 to -0.026), length of about 89mm |

| The total mass of the loading block and the model fixture assembly should be | large (795 ± 7) g, small (595 ± 7) g |

5.Determination of fabric pilling performance: 1. The distance between the drive shaft and the central axis is (12 ± 0.25) mm; 2. The total mass of the model fixture assembly (sample fixture, specimen holder ring, model fixture guide shaft) should be: (155 ± 1) g 3. Load block (1): (260±1)g 4. The total mass of the model fixture and the loading block is (415±2)g 5. Felt: top (style fixture) diameter is 90±1mm Attachment: 1) Sheep felt: diameter 140mm, thickness: 2.5±0.5mm, mass per unit area 750±50m2; 2) Friction cloth: diameter of at least 140mm; testing over 50,000 rpm requires replacement of abrasive. 1. Number of stations: 6Heads 2. PLC control, touch screen display 3. Pressure weight a. Holder: 200±1g b. Clothing sample weight: 395±2g c. Furniture ornament sample weight: 594±2g d. Stainless steel butterfly: 260±1g 4. Effective friction diameter of the grinding block: Type A 200g (1.96N) friction head ¢ 28.8 -0.084mm Type B 155g (1.52N) friction head ¢ 90 -0.10mm 5. Relative movement speed of the holder and the grinding table: 50-2r/min 6. Loading hammer quality: 2385±10g 7. Power: 220V 50Hz 8. Number of test heads: 6 9. Distance of the drive shaft from its central axis: (30.25 ± 0.25) mm 10. Ratio of external transmission speed to internal transmission speed: 16:15 11. The maximum stroke of the pattern clamp guide in the longitudinal and lateral directions is (60.5±0.5)mm 12. Pressure hammer: mass: 2.5±0.5kg, diameter 120±10mm; 13. Anti-friction sample set: load weight + guide shaft + friction head, the total mass should be 198 ± 2g; 14. Specimen clamp pin: diameter 7.950 (-0.013 to -0.026), length about 89mm; 15. The total mass of the loading block and the style fixture assembly shall be: large (795 ± 7) g, small (595 ± 7) g 16. Panel Language: Russian Panel (Custom) |

Corporte partners

Company Certification

Company profile

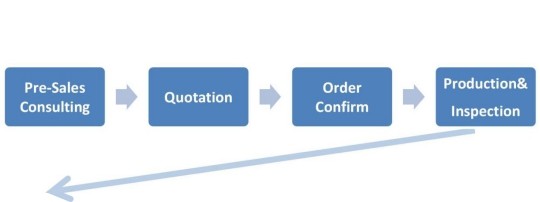

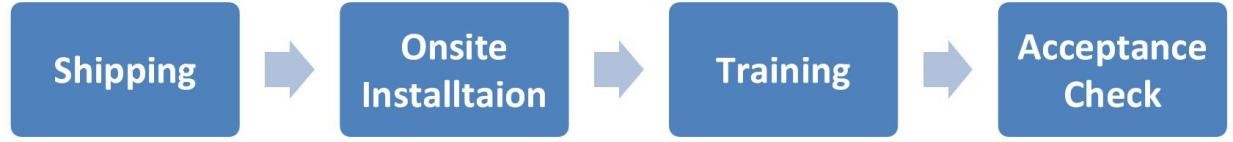

Service Process

| Free Pre-Sales Consulting GAOGE-TECH offer 12 hours quick pre-sales response and free consulting. Any kind of technical support is available for users. We offer progressing solution design to all the users. |

| 20 Days Quick Delivery We have mass production and stock & ready item, for these items, we offer 20 days quick delivery time. For big machine and special requirement, we will trade you as the priority customer and to produce your cargo for the first time. |

| 1 Year Quality Guarantee GAOGE-TECH 1-year guarantee for our machine. And to become you are our long-term customer, we will prolong the quality guarantee period especially for you. |

| 12 hours Quick Feedback & After-Sales Service We will offer "Training Video", "Instruction Book", "Operation Manual" to you, which is easy to learn and operate. We will supply brochures for simple trouble-shootings of the machine, which will help you deal with the common problems happened to the machine. We will offer plenty of technical support online, just like detailed technical and installation instructions. For example, when you meet a maintenance problem, we will make a video with completed and detailed operation process according to the problem, it just seems that I am on the spot by your side to instruct you how to deal with the problem. |

| Quick Back-up Parts Available & Technical Assistance Our extensive inventory of spare parts means replacements get shipped to you as quickly as possible. Immediate technical assistance is only an email or phone call away. |

| Free Training Service We insist that our customers receive personal, hands-on training with every machine we sell. This training is free, and we will work with you for as long as it takes to ensure you feel comfortable operating your machine. We pride ourselves on our expertise and our ability to educate our customers in the installation, proper maintenance, and most efficient use of GAOGE-TECH machines. |

| Special Designing, Customized, OEM Order is accepted GAOGE-TECH is rather willing to help you to realize your special testing and requirement by our innovative ability. So please do not hesitate to contact us when you need special design or customized machine and OEM machines. |

16.Packaging & Shipping

1.Inside is covered with plastic film before we put them into the

plywood, which has good transparency, impact resistance, tasteless

and prevent moisture corrosion.

2.Outside is strong plywood and accord with export standards.

3.We can ship testing equipment according to customer request.