Jiangsu Qiangli Machinery Co.,Ltd |

|

WC67Y - 40 / 2500 CNC Hydraulic Metal Master Press Brake With Throat Depth 200mm

The whole structure of the hydraulic folding machine:

- Totally European design,streamlined looking,Frame: consists of right and left wall boards, working table, oil box, slot steel and etc. The stress of the welded parts can be eliminated by vibration. The machine enjoys high accuracy and high strength and

can be transported easily

- Welded structure: the stress of the welded parts can be eliminated by vibration; so this forging press gives high accuracy.

- High accuracy,high efficiency,simple and convenient operation,good performance, favorable price and best service.

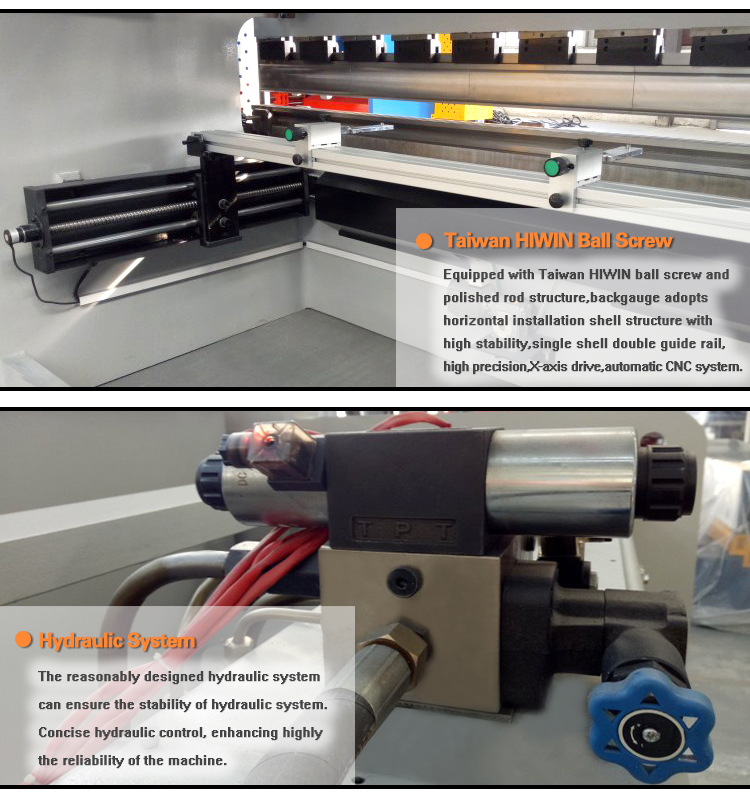

1. Hydraulic system:

- Adopt integrated hydraulic control system, more reliable and easy for maintenance. The hydraulic system consists of motor, oil pump and valve groups and it is installed at the top of the oil box.

- Every complete working cycle can be achieved through the control of hydraulic valve.The remote adjustment valve can adjust the working pressure at the right side of the wall board.

- All seals in cylinder is imported,the most famous brand,good quality and high performance

- Overload overflow protection is outfitted to hydraulic system,which can assure no leakage,and the oil level can be read or seen directly

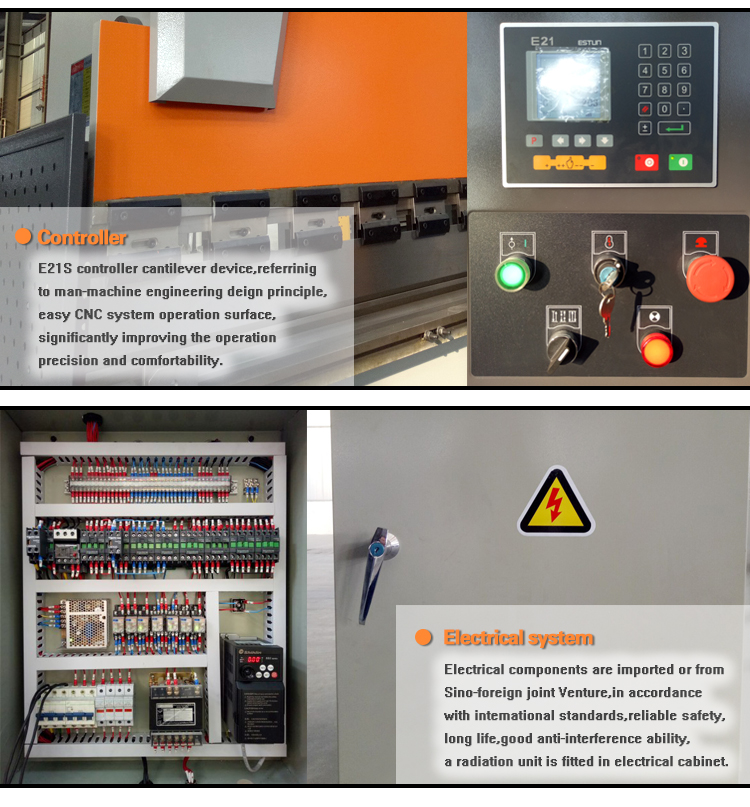

2. Electrical system and the safety interlock:

- Electrical components are imported or from Sino-foreign joint Venture,in accordance with international standards,reliable safety,long life,good anti-interference ability,a radiation unit is fitted in electrical cabinet.

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

- The machine by the European Union CE certification and ISO quality system certification

3. Synchro control system:

- Slide syncho system: adopt steel torsion bar synchro system, simple in structure and high in accuracy

- 2 ends of slide has 2 synchro fork which make,The system uses upper die compensation to improve the brake precision.

- The worktable adopts the particular design,reducing the crowning distortion amount of lower tool effectively.

4. Ram structure:

- Upper stroke design for bending,low noise,stable operating situation.

- Can move the ram up slowly,which allows the operator to control work piece conveniently.

- Universal fixing-surface of the upper tool can be meeting with the clamping requirement of the tool farthest.

- Separate sectional clamping bars are supplied as standard equipment in order to securely fasten short dies.

| No | Model | Pressure KN | Bending Leng (mm) | Columns Distance (mm) | Open Height (mm) | Throat Depth (mm) | Slide Stroke (mm) | Motor Power (kw) | Machine Size (mm) |

| 1 | 40T/2500 | 400 | 2500 | 1900 | 210 | 200 | 110 | 4 | 2600x1270x1980 |

| 2 | 63T/2500 | 630 | 2500 | 1900 | 235 | 250 | 120 | 5.5 | 2600x1360x2050 |

| 3 | 63T/3200 | 630 | 3200 | 2600 | 235 | 250 | 120 | 5.5 | 3300x1360x2050 |

| 4 | 80T/2500 | 800 | 2500 | 1900 | 320 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 5 | 80T/3200 | 800 | 3200 | 2600 | 320 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 6 | 80T/4000 | 800 | 4000 | 3100 | 320 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 7 | 100T/2500 | 1000 | 2500 | 1900 | 330 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 8 | 100T/3200 | 1000 | 3200 | 2600 | 330 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 9 | 100T/4000 | 1000 | 4000 | 3100 | 330 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 10 | 100T/5000 | 1000 | 5000 | 4100 | 330 | 320 | 150 | 7.5 | 5100x1400x2380 |

| 11 | 125T/2500 | 1250 | 2500 | 1900 | 330 | 320 | 150 | 7.5 | 2600x1400x2380 |

| 12 | 125T/3200 | 1250 | 3200 | 2600 | 330 | 320 | 150 | 7.5 | 3300x1400x2380 |

| 13 | 125T/4000 | 1250 | 4000 | 3100 | 330 | 320 | 150 | 7.5 | 4100x1400x2380 |

| 14 | 125T/5000 | 1250 | 5000 | 4100 | 330 | 320 | 150 | 7.5 | 5100x1400x2380 |

| 15 | 160T/2500 | 1600 | 2500 | 1900 | 400 | 320 | 200 | 11 | 2600x1550x2580 |

| 16 | 160T/3200 | 1600 | 3200 | 2600 | 400 | 320 | 200 | 11 | 3300x1550x2580 |

| 17 | 160T/4000 | 1600 | 4000 | 3100 | 400 | 320 | 200 | 11 | 4100x1550x2580 |

| 18 | 160T/5000 | 1600 | 5000 | 4100 | 400 | 320 | 200 | 11 | 5100x1550x2580 |

| 19 | 160T/6000 | 1600 | 6000 | 4800 | 400 | 320 | 200 | 11 | 6100x1550x2580 |

| 20 | 200T/2500 | 2000 | 2500 | 1900 | 435 | 320 | 200 | 15 | 2600x1650x2900 |

| 21 | 200T/3200 | 2000 | 3200 | 2600 | 435 | 320 | 200 | 15 | 3300x1650x2900 |

| 22 | 200T/4000 | 2000 | 4000 | 3100 | 435 | 320 | 200 | 15 | 4100x1650x2900 |

| 23 | 200T/5000 | 2000 | 5000 | 4100 | 435 | 320 | 200 | 15 | 5100x1650x2900 |

| 24 | 200T/6000 | 2000 | 6000 | 4800 | 435 | 320 | 200 | 15 | 6100x1650x2900 |

| 25 | 250T/2500 | 2500 | 2500 | 1900 | 435 | 320 | 200 | 18.5 | 2600x1750x3070 |

| 26 | 250T/3200 | 2500 | 3200 | 2600 | 435 | 320 | 200 | 18.5 | 3300x1750x3070 |

| 27 | 250T/4000 | 2500 | 4000 | 3100 | 435 | 320 | 200 | 18.5 | 4100x1750x3070 |

| 28 | 250T/5000 | 2500 | 5000 | 4100 | 435 | 320 | 200 | 18.5 | 5100x1750x3070 |

| 29 | 250T/6000 | 2500 | 6000 | 4800 | 435 | 320 | 200 | 18.5 | 6100x1750x3070 |

| 30 | 300T/3200 | 3000 | 3200 | 2600 | 435 | 350 | 200 | 22 | 3300x1850x3285 |

| 31 | 300T/4000 | 3000 | 4000 | 3100 | 435 | 350 | 200 | 22 | 4100x1850x3285 |

| 32 | 300T/5000 | 3000 | 5000 | 4100 | 435 | 350 | 200 | 22 | 5100x1850x3285 |

| 33 | 300T/6000 | 3000 | 6000 | 4800 | 435 | 350 | 200 | 22 | 6100x1850x3285 |

| 34 | 400T/3200 | 4000 | 3200 | 2600 | 520 | 400 | 250 | 37 | 3300x2000x3230 |

| 35 | 400T/4000 | 4000 | 4000 | 3100 | 520 | 400 | 250 | 37 | 4100x2000x3230 |

| 36 | 400T/5000 | 4000 | 5000 | 4100 | 520 | 400 | 250 | 37 | 5100x2000x3230 |

| 37 | 400T/6000 | 4000 | 6000 | 4800 | 520 | 400 | 250 | 37 | 6100x2000x3230 |

| 38 | 400T/7000 | 4000 | 7000 | 5600 | 520 | 400 | 250 | 37 | 7100x2000x3230 |

| 39 | 500T/4000 | 5000 | 4000 | 3100 | 600 | 400 | 300 | 45 | 4100x2400x3710 |

| 40 | 500T/5000 | 5000 | 5000 | 4100 | 600 | 400 | 300 | 45 | 5100x2400x3710 |

| 41 | 500T/6000 | 5000 | 6000 | 4800 | 600 | 400 | 300 | 45 | 6100x2400x3710 |

| 42 | 500T/7000 | 5000 | 7000 | 5600 | 600 | 400 | 300 | 45 | 7100x2400x3710 |

| 43 | 500T/8000 | 5000 | 8000 | 6200 | 600 | 400 | 300 | 45 | 8100x2400x3710 |

| 44 | 600T/4000 | 6000 | 4000 | 3100 | 600 | 400 | 300 | 45 | 4100x2650x3750 |

| 45 | 600T/5000 | 6000 | 5000 | 4100 | 600 | 400 | 300 | 45 | 5100x2650x3750 |

| 46 | 600T/6000 | 6000 | 6000 | 4800 | 600 | 400 | 300 | 45 | 6100x2650x3750 |

| 47 | 600T/7000 | 6000 | 7000 | 5600 | 600 | 400 | 300 | 45 | 7100x2650x3750 |

| 48 | 600T/8000 | 6000 | 8000 | 6200 | 600 | 400 | 300 | 45 | 8100x2650x3750 |

| 49 | 700T/4000 | 4000 | 4000 | 3100 | 640 | 500 | 300 | 55 | 4100x2850x3970 |

| 50 | 700T/5000 | 5000 | 5000 | 4100 | 640 | 500 | 300 | 55 | 5100x2850x3970 |

| 51 | 700T/6000 | 6000 | 6000 | 4800 | 640 | 500 | 300 | 55 | 6100x2850x3970 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date.

During guarantee period, we will provide spare parts without any

charge in case of quality discrepancy caused by us. If the

malfunctions are caused by customers’ incorrect operations, we will

provide customers spare parts at cost price. We also can offer

flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing

operation details on condition of you provide the round-trip air

tickets, visa formalities, food and accommodation. In turn, your

engineers can come to our factory for learning the installation,

operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials

to do the test. Only guarantee the machine shows best performance,

and then we will ship out.

2. Our elite teams can provide you professional, customized, and

all-round services around the clock. If you need any help, contact

us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing

solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg.

standard products, we can offer professional recommendations; reg.

non-standard products, we can offer professional designing.