Xinxiang HUAYIN Renewable Energy Equipment Co., Ltd |

|

Rubber Pyrolysis Machines Tyre Recycling Plant To Diesel Plant

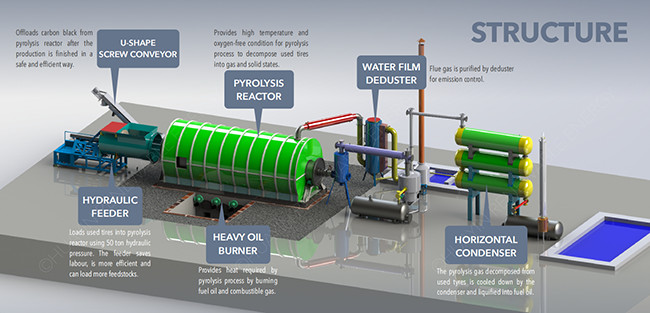

Description of Huayin tyre pyrolysis equipment

Waste rubber pyrolysis machine is used for converting old tires , rubber to industrial fuel which can be used for burning , and the fuel oil can be further refined to diesel that can be used for diesel engines like trucks , tractors etc.

Output product and their usage

Fuel Oil

1. Used as the heating material and sell it to cement factories,

glass factories, ceramic factories, electric power factories, steel

making factories, boiler factories, etc.

2. Used in heavy oil generator for electricity generation.

3. Deep process it into diesel oil with our distillation plant,

color and smell removal system, the final oil can be used in diesel

engines like trucks, tractors, etc.

Carbon Black

Slag for construction.

Steel Wire

It's easy to sell to scrap metal dealers.

COMBUSTIBLE GAS

Combustible gas is routed to the heating system as a fuel supply. It saves the consumption of fuel oil.

Tyre Pyrolysis Plant Work Process

Feeding Of Used Tires (2.5 Hours) :Put the raw material into the pyrolysis reactor . Huayin offers auto feeder machine to help feeding , saving time and labour. As long as the size of the tire is not larger than 1.4 meters, the tire can be directly put into the reactor. If they are larger OTR tires, we supply tire cutting machine

Starts Heating (2 Hours) :When feeding is finished, closes the feeding port then ignites the heating system. The internal temperature goes up slowly in the first 2 hours.

Oil Production (10 Hours): Used tires break down into gas state and solid state under pyrolysis reaction. The gas state enters condensing system, gets liquified and becomes liquid fuel. The oil production process lasts 10 hours. The solid state that is carbon black and steel wire stays inside pyrolysis reactor waiting for discharging.

Cooling Down (3 Hours):When oil production is finished, leaves the machine to cool down for 3 hours before discharging.

Discharging Carbon Black and steel wire ( 3 Hours): Discharges carbon black from reactor by U-shape conveyor. It takes around 2.5 hours. Discharges steel wire mass from reactor by winch. It takes around 30 minutes.

Parameter of rubber pyrolysis machine

| Model | HY-05 | HY-08 | HY-10 | HY-15 | HY-30 |

| Capacity | 5 t/d | 8 t/d | 10 t/d | 15 t/d | 30-35 t/d |

| Working Type | Batch | Batch | Batch | Batch | Continuous |

| Reactor size(m) | D2.2*L5.5 | D2.6*L6.6 | D2.8*L6.6 | D2.8*L8.1 | D1.2*L24 |

| Reactor material | Q245R | Q245R | Q245R | Q245R | 310S stainless steel |

| Power | 29.4KW | 29.4KW | 32KW | 34KW | 100KW |

| Heating Fuel | Pyrolysis oil /coal/ wood/natural gas | ||||

| Burners | 3*300,000 kcal | 3*300,000 kcal | 3*300,000 kcal | 4*300,000 kcal | 12*30000kcal |

| Working pressure | Normal | Normal | Normal | Normal | Normal |

| Landing Area | 200m2 | 250m2 | 300m2 | 350m2 | 700m2 |

| Number of Containers | 1*40FR+1*40HQ | 1*40FR+2*40HQ | 1*40FR+2*40HQ | 1*40FR+2*40HQ | bulk cargo |

Standing features of Huayin Tyre Pyrolysis plant for sale

Safety: Alarm, auto pressure releasing device, anti backfire device, vacuum pump to ensure the machine working smoothly.

Oil-water separator: Its water sealing design ensures that oil and gas are separated and combustible gas can not return to the reactor.

Energy-saving:

The inner reactor body and outside insulation cover have good airtightness, avoiding heating loss and saving fuel.

The combustible gas that cannot be further cooled down into fuel oil will be recycled to the furnace for heating the reactor, maximizing resource utilization.

The cooling water adopts a circulating mode, which is pollution-free, no discharging, and recyclable.

High efficiency discharging: Adopt screw conveyor discharging device, discharge carbon black in sealed condition, no pollution and save labor and time.

Fast installation: All of the condensing parts have been installed together before delivery from the factory, saving installation time and ensuring welding quality.

Auto feeder machine to feed raw material automatically, save labor and time.

FAQ

1. Are there any requirements for the size of the raw material ?

Yes, if the tires waste and plastic bales are within 1.4m , then they can be fed into the reactor directly , if not , they are needed to be crushed.

2. Can waste tyre and plastic be pyrolyzed together at the same time?

Better not mixed them together. The pyrolysis temperatures of them are different , so it will affect the quality of the pyrolysis oil and carbon black. We recommend customers to classify the tires and plastic separately.

3. Is pyrolysis a green technology ?

Yes, the discharged smoke can reach the emission standard with Huayin powerful dedusting system. The flue gas will firstly washed with water then purifed by ceramic packing deduster device. For European customers , we have deduster with higher configuration, desulfurization tower and denitrification tower.