Xinxiang HUAYIN Renewable Energy Equipment Co., Ltd |

|

Skid Mounted Pyrolysis Machine Waste Plastic To Bio Diesel And

Petrol Plant

Product description

Micro-negative pressure high temperature pyrolysis technology for

waste plastic is one of the promising waste plastic treatment

methods. It decomposes the organic components of the plastic by

heating at a high temperature of 500-700 ℃ under the condition of

anaerobic, so as to obtain fuel oil, carbon black, combustible gas.

| Output Products | Application |

Fuel Oil | 1. Used as the heating material and sell it to cement factories,

glass factories, ceramic factories, electric power factories, steel

making factories, boiler factories, etc. 2. Used in heavy oil generator for electricity generation. 3. Deep process it into diesel oil with our distillation plant, color, and smell removal system, the final oil can be used in trucks, tractors, etc. |

| Carbon Black (30%-35%) | Slag for construction. |

| Flammable Gas (8%-10%) | 1. Recycled into the furnace to heat reactor instead of

coal/wood/oil/natural gas. 2. Storage the exceed gas to restart the next batch. |

Advantages of Main parts of the pyrolysis plant

Pyrolysis reactor :

1. The pyrolysis reactor offers an oxygen-free and high-temperature

working condition for pyrolysis process of feedstocks.

2. Manufactured with good material of Q245R boiler plate.

3. The rollers are engineered under the feeding port and oil outlet

port which is external from the heating area to bring perfect

rotating balance and long service life.

4. Safe operation.

Auto feeder:

1.Hydraulic feeder can load more feedstocks since it can compact

feedstocks while feeding.

2.Less feeding time and more loading capacity than manual feeding.

3.No workers enter inside the pyrolysis reactor to ensure safe

operation.

4.Short internal time to start the next production batch.

Horizontal condenser:

1.Condensing process is divided into three stages. Pyrolysis gas

passes through horizontal condenser pipe x1, horizontal condenser

×3 and vertical condenser x1 in sequence, to maximize the

condensing effect.

2.Combustible gas (non-condensable gas) is collected by the system

and routed to the heating system as a fuel supply. It saves fuel

consumption meanwhile protect the environment.

Deduster :

1.The stainless steel deduster is filled with ceramic filters inside,

which brings it strong dust adsorption capacity and good dust

control effect.

2.Stainless steel material provides long life span for deduster.

3.Easy installation and maintenance.

Specification

| Product model | HY-10T |

| Overall Dimension | 35M*11M |

| Total Weight | 32Ton |

| Working Mode | Batch type |

| Average Power | 15KW |

| Power Voltage | 380V |

| Unit Loading Volume | 40.6m³ |

| Average Loading Capacity | 10Ton |

| Average Oil Yield | 40% |

| Electricity Consumption | 360 kwh/batch |

| Fuel Consumption | 350L fuel oil |

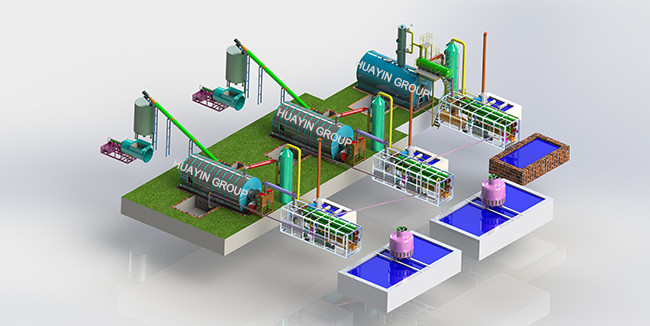

Layout design

Details Images of the pyrolysis plant