QINGDAO SINO-HOLYSON MACHINERY CO., LTD |

|

Verified Suppliers

|

|

HSJZ-65/132 PVC Wall and Ceiling Making Machine

This machine is mainly designed for manufacturing both PVC Wall/Ceiling Panels and PVC U/L Angle Lines, which mainly used in home decoration. The Machine adapts to various formulations, the ratio of calcium can be increased up to 50%-250%, while the required accessories can be reduced by 30%. Laser tracking eliminates problems regarding the extrusion flow rate, which helps achieve automation of the entire extrusion process

MOLD Design: Width:200/300 mm, Customized according to the Sample

Model | HSJZ-51/105 | HSJZ-55/128 | HSJZ-65/132 | HSJZ-80/156 |

Motor Power(kw) | 22kw | 30kw | 37kw | 55kw |

Output(kg/hr) | 80-120kg/hr | 100-150kg/hr | 150-250kg/hr | 200-350kg/hr |

Daily Production Capacity(m2) | 600m2 | 800-1000m2 | 1500m2 | 3000m2 |

HSJZ-55/128 mm Conical Twin Screw Extruder

This Extruder is designed specially for processing Higher Percent Calcium Mixed PVC Material, to manufacture PVC Wall/Ceiling Panels. The Extruder installs with 30 kw driving motor , which will produce 700-1000 sqm panels. Our SCREW & BARREL Sets is specially designed for 200-260% Calcium mixed. It has the advantages of high tenacity, high impact, good bending performance, high temperature resistance, etc.

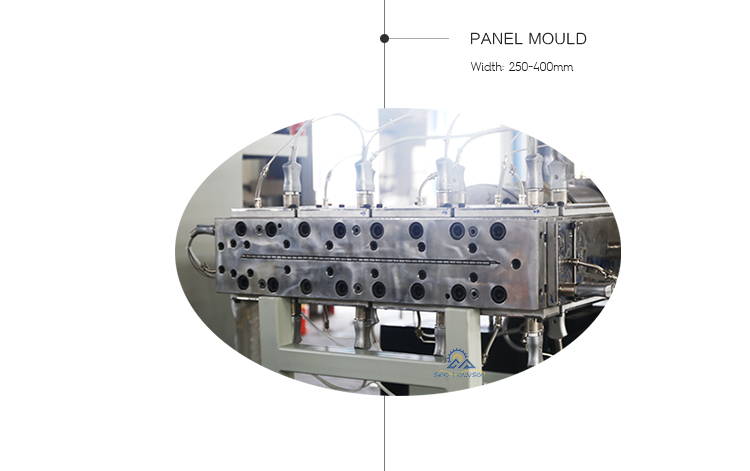

Wall & Ceiling Panel Mould

We can make all kinds of molds according to customer requirement. Die design is based on flow simulations on our computer, flow analysis and experience, that leads to excellent flow characteristics.

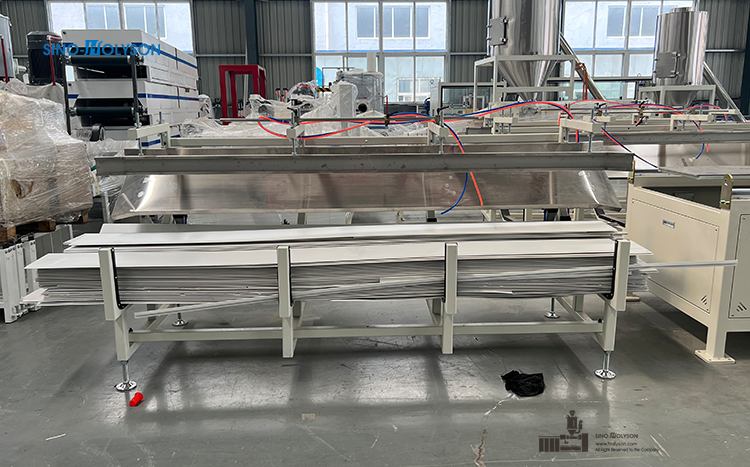

Vacuum Calibration Platform

This unit is mainly used for cooling and shaping the panels after the extrusion mold to help the PVC products fast finalization and guarantee it not out of shape. It is installed with 4 kw vacuum pump and 3 kw water pump, for reliable production.

Haul off Machine

With each crawler driven by frequency motor, this machine can automatically change its working speed synchronous with the whole production line speed.The caterpillar is soft and it can protect panels well while it works.

This unit is specially for wall and ceiling panel production. It's a perfect match to the shape of the panel. The pressing rubber wheels direction or angle can be adjusted accordingly as per panel design. With a higher speed production, makes it very effective for the panel suppliers.

This unit is mainly for collecting the panels after proudction. It will discharge the panels automatically and piles the panels into bundle. It can automatically cut with set length, auto counting function.

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.