QINGDAO SINO-HOLYSON MACHINERY CO., LTD |

|

Verified Suppliers

|

|

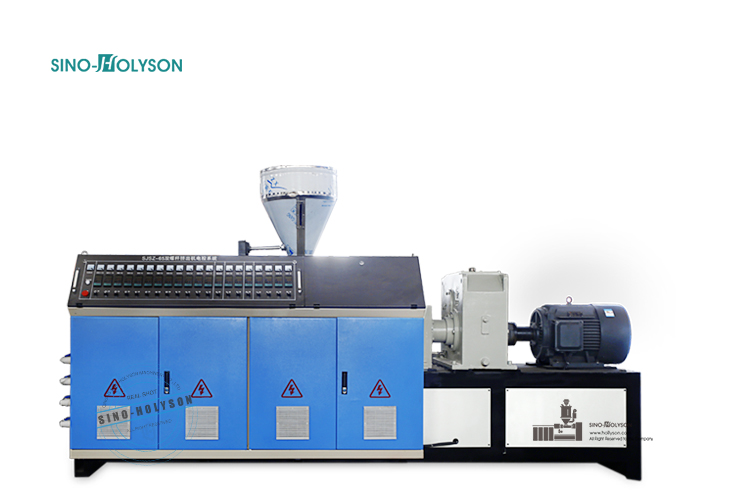

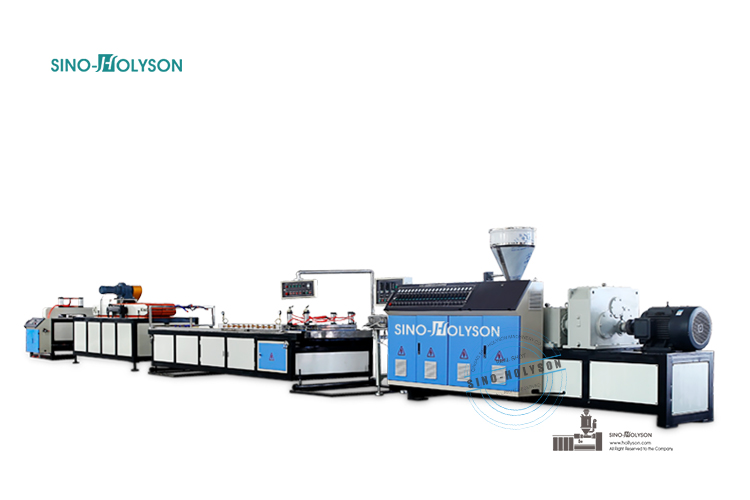

SJZ-80/156 Foam Board Conical Twin Screw Extruder Production Line

with 75 rpm Screw Speed

SJZ 80/156 CONICAL TWIN SCREW EXTRUDER

General Introduction:

SJZ-80/156 CONICAL DOUBLE SCREW EXTRUDER is an efficient mixing and extrusion equipment. The machine has the characteristics of low shear rate, difficult to decompose, uniform plasticizing and mixing, stable quality, high output, wide application range, long service life and PVC powder direct molding. With all kinds of mould and auxiliary machine production line produced by our company, the conical double extruder can directly make PVC powder into different plastic products such as plastic pipe, plate, profile, board, and so on.

Conical twin-screw plastic extruder electrical control system has two kinds of general control and microcomputer control. The main drive mode has two kinds of DC speed regulation and frequency conversion speed regulation, for users to choose.

Main Features:

1. The soft plasticizing concept is always running through the screw design, which provides a powerful guarantee for high-speed extrusion of UPVC pipes.

2. Reliable two-stage screw core external circulation temperature control system can ensure that different formulations can produce high quality UPVC pipes.

3. High efficiency and low noise air cooling system, reliable and effective vacuum exhaust system, high precision, wide speed regulation, forced quantitative feeding system, high performance deceleration torque distribution gearbox, perfect accurate automatic temperature control system, precise and stable speed regulation system

4. The specially designed transmission part is driven by a new type of variable frequency motor or DC drive motor, running smoothly, high transmission torque and high efficiency. Through imported frequency converter or DC governor can achieve stepless and stable speed regulation, high accuracy, energy saving.

5. Adopting intelligent digital temperature control instrument with dual display, the control precision is high and the temperature fluctuation is small.

6. With overload protection and fault alarm, screw core oil cycle constant temperature, barrel oil cooling and other functions

Please Note:

1. The extruder should run in a positive direction; avoid reversing.

2. Avoid the cold machine running on an empty stomach, it must be the hot machine with feeding material operation, so as to avoid the occurrence of sticky bars (holding shaft) phenome

Parameter Table:

Model | SJZ-45/90 | SJZ-51/105 | SJZ-65/132 | SJZ-80/156 | SJZ-92/188 |

Screw Diameter | 45/90mm | 51/105mm | 65/132mm | 80/156mm | 92/188mm |

Screw Length | 989mm | 1070mm | 1440mm | 1800mm | 2500mm |

Motor | 15kw | 22kw | 37kw | 55kw | 90kw |

Output | 80-120kg/h | 100-150kg/h | 150-200kg/h | 300-450kg/h | 700-1000kg/h |

SINO-HOLYSON, a professional plastic extruder manufacturer, delivers "MADE-TO-ORDER" service.

Send your sample pictures by mail. Our PROPOSALS will be feedback soon by engineer team.

WE TRUST WITH CE & ISO9001 CERTIFICATION, OUR QUALITY MACHINE WILL SATISFY YOU VERY MUCH.

Pre-Sales Service | After-Sales Service |

* Inquiry and consulting support. * Sample testing support. * View our Factory. | * Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. |

--- OEM & ODM Service Available ---

Before delivery, our working staff will carefully pack the whole set machine to make sure the products arriving to customer's workshop safely.