QINGDAO SINO-HOLYSON MACHINERY CO., LTD |

|

Verified Suppliers

|

|

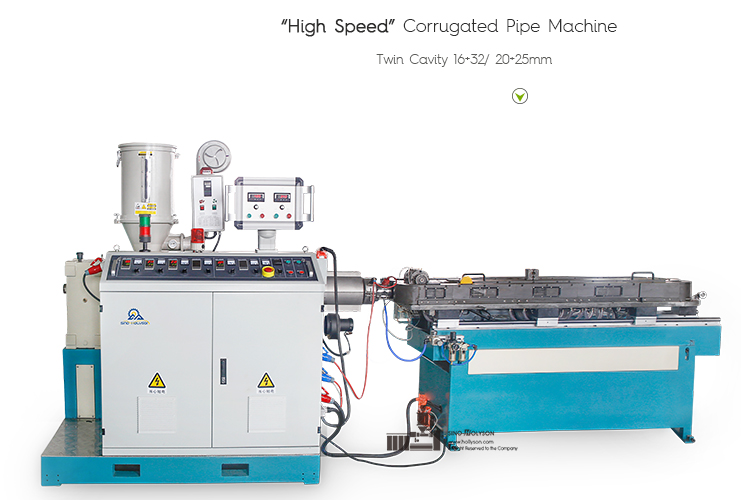

Item Model | Design | Corrugated Pair Size | Driving Speed | Output |

HSJ-65/30 | Twin Cavity, 60 Pairs | L35/56.55/56 | 11-20m/min | 35-50kg/h |

HSJ-65/30 | Twin Cavity, 72 Pairs | L35/56.55/56 | 15-30m/min | 35-50kg/h |