Wuxi Luole Machinery Co., Ltd |

|

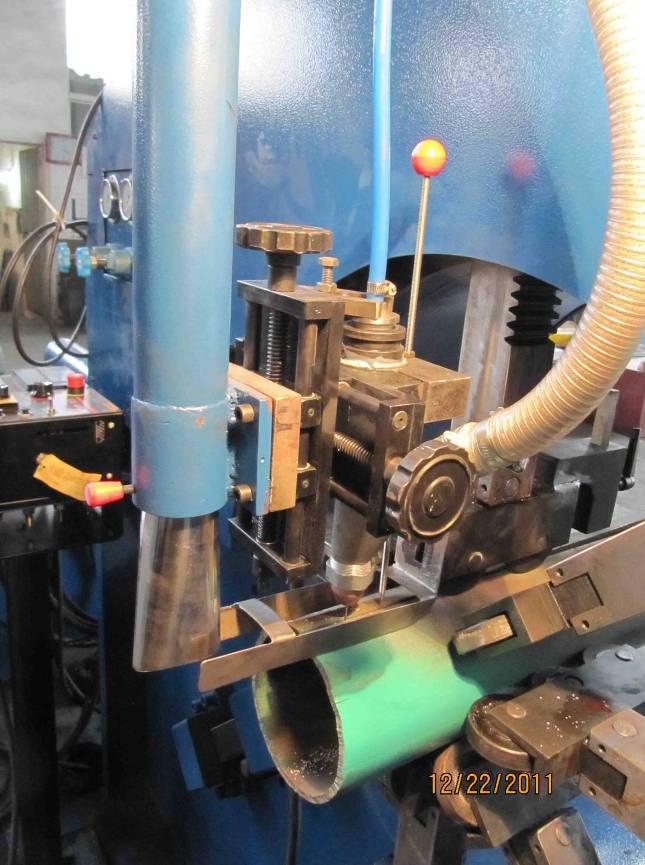

Column Pole Sewing and Welding Machine Use SAW Welding Way by

Direct Current 630A Welding Power

Description:

Light Pole Shut-Welding Machine Model: 500/12000, It Is Suitable

For One Piece Type Polygonal And Circle Taper Light Pole. It Is A

Full Automatic Welding Line, The Moving Trolley With Speed

Adjustable By Vfd Or Can Pull The Light Pole From Small End To Big

End, The Hydraulic Cylinder Through Mechanical Chain, Worm Wheel

Push The Clamping Wheel To Close The Pole And Do Welding At Same

Time.

The machine includes the following items :

Technical Parameters

1 | Workable Diameter | 60-450mm, | |

2 | Workable length | 12000 mm | |

3 | DOLLY LENGTH | 1500 MM | |

4 | Suitable light pole thickness base | Light pole diameter: 60~450mm | 2.8~3mm |

Light pole diameter: 70~450mm | 2.8~4mm | ||

Light pole diameter: 250~450mm | 2.8~6mm | ||

5 | Power of Motor for Pump | 4 KW | |

6 | Power of Motor for pulling dolly | 4 KW, AC speed changeable type. | |

7 | Welding Machine | 630A, (Submerged Arc Welding and | |

8 | Welding wire diameter | 1.2,1.6,2,4

mm welding wire, according the pole | |

9 | Working Speed | 1.1~2m/min (Note: different thickness speed | |

10 | Gross weight | 7500 | |

11 | Overall sizes (mm) | 22000x2000x2000 mm (L x W x H) | |

Deatil of Machines

Lincoln welding machine (USA BRAND)

Note:, If chose the Lincoln welding machine,normally it is suitable for Submerged Arc Welding

process

Fast motorized return back for moving

trolley

Note:for the standard machine, the dolly return back can be motorized with working speed, it

is very slow for return back process. So, normally, the operator will open the dolly clutch and

push the dolly by manual.

In order to reduce the manpower, we have option: Fast motorized return back for dolly. The

operator only push button, the dolly will be back to the welding head.

See attached detail photos.

Both Side additional hydraulic cylinder

It is suitable for small diameter big thickness light pole, or steel plate with high tensile

strength light pole.

With this additional option , the diameter from 60~450mm, thickness 2.8~6mm, all pole can be

suitable. And easy for operation.

Applications:

Electricity pole and lamp pole was widely used

in the countryside and city ,such as electricity transport

pipe , shine lamp pole ; blinker , Offshore,Petro

Chemical ; Plate Heat Exchanger ; Charged air cooler ; Pressure

Vessel ;Pipe system&Steel works etc.

Competitive Advantage:

1. All the bolt using 12.9 grade Bolt , not using 8.4 grade. Making

the machine more stronger.

2. 20 % overweight design , could making the rotator focus more.

3. Double row wheels ,not only making the wheels stable, but also

artifacts to increase friction.

4. All the parts using well-known brands in China or other

countries . Quality is more reliable .

5. Using double row bearings.

6. The base of rotator welded by plates, with high strength, no

deformation after long time using.

Why choose my factory?

Quality and services

1.The course of designing, producing and selling are performed

according to iso 9001.

2.Our company can suplly study , installation and provide parts and

repairing service all of the life.

3.Free training and take charge of the adjusting.

4.When equipment arrived, do well of the after service on

time,reply in 6 hours and arrive to user ends in three work days.