Wuxi Luole Machinery Co., Ltd |

|

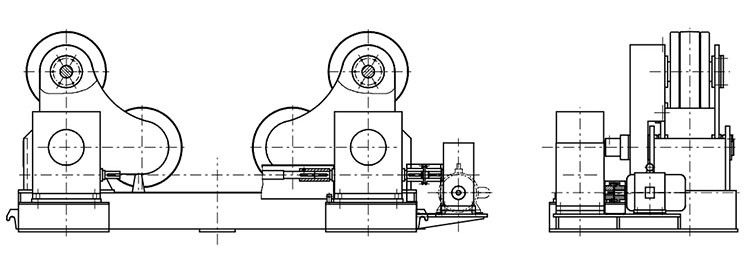

Loadfing and Driving Capacity 20T Self Aligning Welding Rotator Use Wireless Box Control Working Speed by Danfoss VFD

Advantages of Self aligning welding rotator

1. It will adjust the tank diameters automatically.

2. Wireless control is more convenient than remote control cable.

3. Working range can be designed according to your tank diameter.

4. Low noise transmission and stable turning roller during working.

Delivery Package Range

1. One set powered / One set idler / Electric control system

2. Voltage : 380V 50Hz 3P

3. Control Way : Remote Control Box / Foot Pedal

4. Package Way : Wooden Case / Steel frame

5. Working Manual

Technical Data

Model No. | Max loading | Motor power | Linear guide | Roller material | Working Range |

HGZ-20 | 20T | 1.5 KW | 6-60m/h | Rubber | 320-3500mm |

Applications

1. The machine consists of 1 set of driving roller, 1 set of idler

roller and electric control system.

2. The drive roller and idle roll must be put the foundation in

same horizon. Two sets roller must be parallel to put, the ground

horizontal plane must even. If the long-term usage base needs to be

fixed.

3. Ensure that there is ample space for movement of the equipment,

work piece as well as the operator.

4. The worm wheel decelerator of the machine adopts lubricating

oil, other gears and bearings adopt grease lubrication, periodic

change. Note: the lubricating oil isn't oiled into the machine at

shipping, the users must oil assigned lubricating oil, and then

begin to use.

5. Connect the 3-phase power supply only after all the mechanical

and electrical installations have completed. Ensure that the phases

are correct, if not the unit will not power up.

Details Control system and Brand

1. Inverter is from Taida/Yaskawa Brand

2. Motor is from CE Invertek Brand

3. Reducer is from Cable. Made in China.

4. Electric system is from Schneider