Wuxi Luole Machinery Co., Ltd |

|

C & Z Purlin Interchangeable Carbon Steel Cold Bending Machine / Metal Roll Forming Machine Imported from China

Machine Overview :

C,Z purline adopt high strength steel plate and shaped after cold

forming, it has wall thickness homogeneous, size and dimension can

be adjusted, big compression strength ect characteristics. The C

purline machine which after cold forming, although the section

dimension is light, it corresponds with carrying capability’s

feature for roof purline and makes steel’s mechanical efficiency

into full playing. It can make the C,Z purline can lighten the

construction roof’s weight, reduce project steel quantity. So it

becomes economic high efficiency steel. It is new building material

instead of angle iron, channel steel, steel tube and tradition

purline. C,Z purline and light metal tile using together is the

best choice for light steel construction.

Automatic Change Size Customized C & Z Purlin Roll Forming Machine can produce purlins into C, Z and U shape automatically, all the purlin sizes can be set on PLC control screen, and produce corresponding size under the program setting task. Our Automatic Change Size Customized C & Z Purlin Roll Forming Machine is strong for producing thick hot rolled coil and GI, cold rolled coil, compare to manually type change purline roll forming machine, it can save human cost and time cost much.

Main Features of C/Z Purlin Roll Forming Machine

1 C/Z Purlin machine can produce both C Purlin and Z Purlin. The C

change into Z operations is easy.

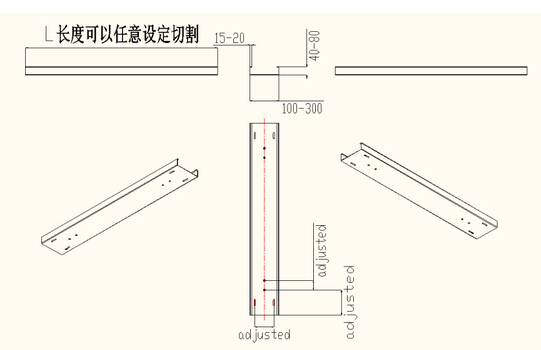

C purlin size width range: 80-300mm, and Z purlin size width

range:120-300. Also the C/Z Purlin can be designed according to

customers requiry.

2 C/Z Purlin machine can adjust the both C size and Z size quickly

,by adjust backboard , and very easy operation.

3 The cutting parts no need to change the mold, just by adjust

certain size, it can cutting the Purlin properly.

4 C/Z Purlin machine can save much of the workshop place.

Detail Specifications

1. 5 Ton Passive Decoiler

1) Structure of pedestal, braking, mandrel holder, slider narrow

and expanding

2) Capacity of decoiler:5Ton

3) Max. width: 500mm

4) Inner diameter for coil: 440mm-530mm

5) Out diameter: 1500mm

2. Feeding Guider & Straighten Device

1) The purpose is to guide the metal sheet into the roll forming

machine and make sure the metal sheet at the correct position with

the roll forming system.

2) It can be left and right adjusted by adjusting the screw. Also

the left and right adjusting can be independent operating.

3) The five roller straighten leveling device is quenched and hard

chrome coated to straighten the rough sheet and reduce the material

strength for roll forming.

4) Motor for feeding and straighten device:5.5KW

3. Hydraulic System for Punching and Pre-cutting Device

1) This device consisted by punching mould, cutting blade, oil

cylinder and hydraulic station.

2) Pre-cutting before roll forming which no need to change cutting

mould.

3) Material of punching and cutting blade:Cr12Mov, quench hardness58-62

4) Power for cutting: Hydraulic power:7.5KW

4. Main Roll Forming Machine

1) Raw Material: forming thickness 1.0-4.0mm, Yield strength Q235

galvanized steel and hot rolled steel

2) Roll forming station: 15 stations

3)Rectify roll station: 2 stations

4) Axis Diameter: ∅85mm

5) Shaft material: 45# high grade steel

6) Roller material:Gcr15 bearing steel, forged and quenched hardnessHRC58-62

7) Roller process: CNC lathe processed, surface polished or black

treated

8) The gap between upper layer rollers and bottom layer rollers can

be adjusted by screw according to different thickness sheet.

9) The interchange from C to Z is only need to adjust two station

rollers

10) Motor power:18.5KW

11) Transmission: High strength chain

12) Working speed:15-20m/min(Not including cutting time)

5. Electrical Control System

1) The whole line controlled by PLC control and frequency speed

control to achieve automatic. The friendly interface can set the

bath, product length and quantity.

2) PLC: Panasonic, Japan

3) Frequency control: YASKAWA, Japan, 18.5KW

4) Other low voltage: Schneider

5) Encoder: Omron

6) Operate panel: Touch screen

6. Run-out Table

Consisted by tubular frame with support rollers to load and

transfer products

The Equipment supplying list is as follows:

Compenent | Qty | Remark |

Decoiler | 1 | Loading the coil material |

Feeding guide device | 1 | Feeding and guide the material sheet |

Straighten and Leveling rollers | 1 | Seven rollers to straighten and leveling material |

Main roll forming machine | 1 | Roll form the metal sheet |

Hydraulic punching device | 1 | Punching holes on the shaped profile |

Hydraulic Cutting blade | 1 | Cutting the formed products |

Hydraulic Station | 1 | Provide power for cutting |

PLC control cabinet | 1 | Electrical control system |

Output table | 1 | Load the finished products |

Sampe Profiles: