PSL (WUHAN) SMART EQUIPMENT CO.LTD. |

|

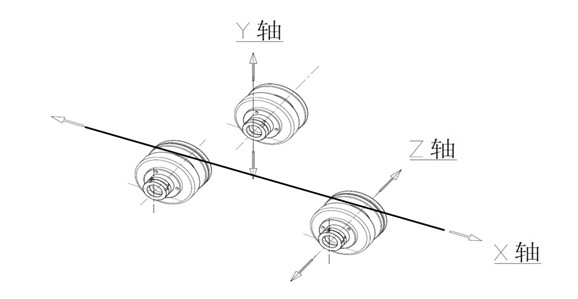

3D Servo driving CNC hydraulic profile rolls bending machine

1. Equipment introduction:

CNC-25T roll bending machine is an efficient cold working equipment for rolling and bending various industrial metal profiles (section size: 200mm * 100mm, bending stress less than 25x10 ^ 3kn).

It can bend various variable curvature multi segment arc two-dimensional workpieces and three-dimensional space workpieces at one time.

2. Equipment function:

It can bend single arc, variable curvature multi segment arc, ellipse, positive and negative arc, spiral arc and other special-shaped arc.

It can bend various three-dimensional workpieces at one time.

When bending complex workpieces (such as ellipse and multi segment arc), rebound measurement can be used to help programming.

The equipment has networking function, and the interface that can be connected to the user's LAN and Ethernet is reserved. It can be upgraded according to the reasonable needs of users (the manufacturer will upgrade it free of charge within the equipment life cycle) for data transmission, remote diagnosis, remote monitoring, etc.

Protection function:

① Safety protection, leakage protection, overload and short circuit protection shall be provided to ensure the safety of operators

② The upper and lower dead center limit device of the sliding block ensures that the sliding block will never exceed the upper and lower dead center position in any operation.

③ Equipped with mold protection, after inputting the mold parameters into the computer, it can ensure that the mold will not be crushed by misoperation.

④ The main motor adopts variable frequency motor and stepless speed regulation. It has overload protection function.

⑤ The hydraulic system only provides working pressure during automatic operation, which reduces the waste of energy.

Operation AIDS:

① There is a side roller device on the two sides of the machine tool, which makes the material more stable in the processing process and helps to take and discharge the material.

② The lower shaft of the machine tool has the function of shaft to shaft adjustment. When bending different profiles, different shaft spacing can make the material forming more stable.

③ It has real-time feedback display at any point, so that the operator can detect the operation of the machine tool at any time.

④ With the help of rebound calculation, the operator can program automatically.

⑤ The light eye system can set the bending starting point position of the workpiece by itself, which can make the same batch of workpieces start bending at a certain position away from the material head, so as to improve the stability of the product.

Control and software functions:

① Follow the man-machine interface design concept, the console control is convenient for operation, and all data are displayed on the display screen.

② The operation panel is a Chinese / English panel, through which data can be edited and stored without loss in case of power failure.

③ The storage capacity of the device is 4G, which can store at least 1000 program files (one program file corresponds to one workpiece), and each program file can write 300 program segments (the more segments, the more conducive to bending multi segment arc workpiece).

④ The software operation interface is divided into different interfaces, such as general roll bending, elliptical roll bending, teaching roll bending and three-dimensional roll bending, which can be freely selected by the operator.

⑤ It has certain automatic programming function.

⑥ It provides manual inching, automatic control, speed magnification adjustment, relative / absolute coordinate switching, material length calculation and other functions, hydraulic pressure program setting, mechanical zeroing, user authority management and other functions.

Advantages and features:

① The user can input the data shape of the profile to be bent from the input device, and can process the profile with variable curvature (two-dimensional), with accurate forming radius and smooth transition between different curvatures. It can complete the roll bending processing of round, square and special-shaped aluminum profiles;

② All commands are easy to understand and easy for the operator to master quickly. When there are some unrealistic or unreasonable errors, the device will prompt on the screen to help the operator quickly eliminate the problem.

③ 0.001mm double wave grating ruler (not single wave) is adopted for the walking feedback of the middle slider, which greatly improves the feedback accuracy and anti-interference ability.

④ It has the function of low speed, large energy and slow stop, which improves the bending efficiency and length positioning accuracy.

⑤ The servo indexing system is a special motion control system. The ideal matching accuracy can be obtained by motion interpolation. It can realize complex multi radian bending deformation of materials.

Parameter index:

| No. | Name | Specifications |

| 1 | Y-axis repeated positioning accuracy | ±0.01mm(with loading) ±0.005mm(without loading) |

| 2 | Z-axis repeated positioning accuracy | ±0.01mm(with loading) ±0.005mm(without loading) |

| 3 | Fourth roller (auxiliary wheel) | The auxiliary wheel has no power to avoid speed difference and scratch the workpiece |

| 4 | Three roll drive | 3*2.2kw |

| 5 | Torque | 7900N.M |

| 6 | Roller diameter | 80mm |

| 7 | Rollers distance | 400,500,600,700 mm |

| 8 | Y-axis travelling | 280mm |

| 9 | Z-axis travelling | 100mm |

| 10 | Effective length of roller shaft | 280mm |

| 11 | Pressure of hydraulic cylinder | 25T |

| 12 | General power | 14.1kw |

| 13 | Voltage | 380V 50HZ |