PSL (WUHAN) SMART EQUIPMENT CO.LTD. |

|

CNC 4 roller plate cone rolling machine Stainless steel metal bending machinery

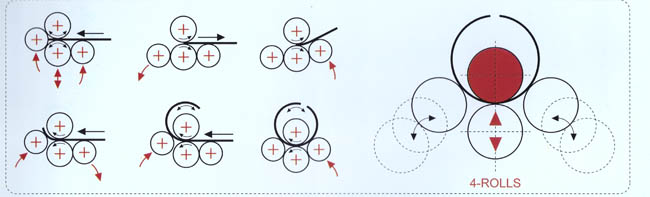

CNC four-roller plate bending machine has the function of pre-bending the end of the sheet. The machine has four work rolls. The work rolls are one of the most important components of the 4-rollers plate bending machine.

The rolls Material: 42CrMo alloy steel, quenching and tempering treatment makes the work roll strength reach HB241-260, comprehensive mechanical properties, high strength, strong wear resistance, suitable for high-load work, long service life.

The lifting displacement is controlled by sensors and PLC, automatically leveled, and displayed on the screen.

4-roller plate rolling machines are with widely types welcomed by customers. With a high technical level, complete functions, high precision, and convenient operation, 4-rolls plate bending machine is an ideal model for rolling round, arc, cone, and special-shaped workpieces.

- Pre-bending and forming of the end of the plate can be completed without turning after the steel plate is loaded.

- Very durable spherical roller bearings are used on each roller of 4 rolls bending machine.

- Yuken or Rexroth products are used for the main valve groups in the hydraulic system. The valve block is a casting flow channel, large overflow, low resistance, low-pressure loss, and low heat generation, which makes the performance of 4 rolls bending machine be more reliable.

- The hydraulic system of the 4 rolls plate bending machine ensures the cleanliness of the system with oil suction and return oil filters. An air filter ensures the normal breathing of the fuel tank and the evaporation of water. Also equipped with a centralized refueling device.

- The tipping frame is equipped with a tipping cylinder, the tipping head can be tipped and upright which is convenient for the workpiece to pick up. The turning and resetting of the turning bearing body are equipped with an interlocking device. The movement can be resumed after the bearing body is reset, which plays a role in safety protection.

- The upper roll tail is equipped with a balance device, which balances the upper roll while the bearing body is turned over. The upper roll is in a balanced state by the balance mechanism when the material is turned upside down so that the cylindrical workpiece can be easily taken out.

- The 4 roll bending machine adopts an integral base, which is strong in rigidity, easy to hoist and install. The frame and base are welded and processed with annealing aging treatment which eliminates internal stress and improves the bending machine precision. The whole structure of 4 roll bending machine is composed of building blocks.

Main Structure of the machine:

The lifting displacement of the machine’s lower roller and lateral roller is controlled by PLC, automatically leveled, digital display on the screen, synchronization accuracy ±0.2mm.

The lower roller and lateral roller of the 4 roll bending machine can be tilted at one end.

The plate bending rolling machine is equipped with a movable operating table, which is more convenient to use by operators. The touch screen displays four work rolls positions and make the operator clear at a glance.

ontrol system adopts the PLC programmable controller of an internationally renowned company. The system has parameter settings, data editing, good alarms, power-off memory, man-machine interface, status display, real-time calculation, file storage, debugging mode, manual mode, program control mode, file editing, fault self-diagnosis, the intelligent judgment of operating errors, and other protection functions; Also has advantages of strong anti-interference ability.

The high-precision sensors are used for lifting and displacement sensors of the machine lower and lateral rollers, which ensure the position accuracy and realize the position monitoring of each roller.

Main Technical specifications,

|