PSL (WUHAN) SMART EQUIPMENT CO.LTD. |

|

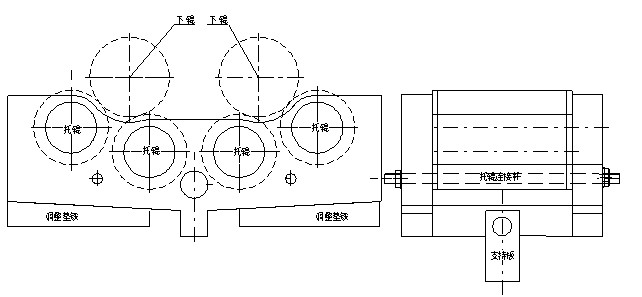

CNC Hydraulic Universal 3-rollers Plate Rolling machine

Discription of this Plate Rolling machine,

The machine is a kind of hydraulic 3-roller bending machine, which is for rolling the plate to the cylinder shape. To pre bend though the upper roller horizontal movement; there is a relative displacement to the lower rollers. The motor and reducer drive the two lower rollers when rounding. Due to the elevation of the lower rollers is constant, so it's convenient to feed and operate. The toppling rack is hydraulic type design.

Technical Data,

| Max width of roll board | W11S-25x3000 |

| The length of working rolls | 3000mm |

| Max thickness of plate | 25mm (Yielding Limit of Steel Plate 245Mpa) 20mm ( stainless steel plate) |

| Max. Thickness of pre-bending | 20mm(Yielding Limit of Steel Plate 245Mpa) 16mm (Stainless steel plate) |

| Up roll diameter | Φ410mm |

| Down roll diameter | Φ235mm |

| Distance between two down rolls | 380mm |

| Drive speed | 4.5m/min |

| Main motor | 30KW |

| Hydraulic motor | 11KW |

| Move motor | 4KW |

| Dimensions | 5850*1950*2150mm |

| Weight | 16500kg |

| PLC | Omron |

| Hydraulic system | Yuken, Japan |

| Electrical elements | Siemens, German |

Functions of upper-roller Universal rolling machine

Main Characteristics

Specifications of W11S Series,

| Specif ication | On roll ease pres sure | Max imum t hickness | Bo ard incr ease m) | The roll dia meter m) | Un der the roll dia meter m) | Center distance (Mm) | Motor (kw) | |||

| End so ng m) | Ce ntral m) | Dri ving | Oil use | Mo bile use | ||||||

| W11S -15*2000 | 75 | 12 | 15 | 2000 | 255 | 150 | 245 | 7.5 | 4 | 1.1 |

| W11S -14*2500 | 75 | 10 | 14 | 2500 | 270 | 150 | 245 | 7.5 | 4 | 1.1 |

| W11S -1913*3000 | 75 | 9 | 13 | 3000 | 290 | 150 | 245 | 7.5 | 4 | 1.1 |

| W11S -17*2500 | 100 | 13 | 17 | 2500 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S -15*3000 | 100 | 11 | 15 | 3000 | 325 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S -20*2500 | 130 | 16 | 20 | 2500 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S -18*3000 | 130 | 14 | 18 | 3000 | 350 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S -22*2500 | 160 | 18 | 22 | 2500 | 360 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| W11S -20*3000 | 160 | 16 | 20 | 3000 | 375 | 200 | 330 | 18.5 | 7.5 | 2.2 | |

| W11S -18*3500 | 160 | 14 | 18 | 3500 | 390 | 200 | 330 | 18.5 | 7.5 | 2.2 | |

| W11S -24*2500 | 190 | 21 | 24 | 2500 | 380 | 220 | 360 | 22 | 7.5 | 4 | |

| W11S -22*3000 | 190 | 19 | 22 | 3000 | 400 | 220 | 360 | 22 | 7.5 | 4 | |

| W11S -20*3500 | 190 | 16 | 19 | 3500 | 410 | 220 | 360 | 22 | 7.5 | 4 | |

| W11S -30*2500 | 230 | 25 | 29 | 2500 | 410 | 235 | 380 | 30 | 11 | 4 | |

| W11S -27*3000 | 230 | 22 | 27 | 3000 | 425 | 235 | 380 | 30 | 11 | 4 | |

| W11S -25*3500 | 230 | 21 | 25 | 3500 | 440 | 235 | 380 | 30 | 11 | 4 | |

| W11S -20*3000 | 160 | 16 | 20 | 3000 | 375 | 200 | 330 | 18.5 | 7.5 | 2.2 | |

| W11S -18*3500 | 160 | 14 | 18 | 3500 | 390 | 200 | 330 | 18.5 | 7.5 | 2.2 | |

| W11S -24*2500 | 190 | 21 | 24 | 2500 | 380 | 220 | 360 | 22 | 7.5 | 4 | |

| W11S -22*3000 | 190 | 19 | 22 | 3000 | 400 | 220 | 360 | 22 | 7.5 | 4 | |

| W11S -20*3500 | 190 | 16 | 19 | 3500 | 410 | 220 | 360 | 22 | 7.5 | 4 | |

| W11S -30*2500 | 230 | 25 | 29 | 2500 | 410 | 235 | 380 | 30 | 11 | 4 | |

| W11S -27*3000 | 230 | 22 | 27 | 3000 | 425 | 235 | 380 | 30 | 11 | 4 | |

| W11S -25*3500 | 230 | 21 | 25 | 3500 | 440 | 235 | 380 | 30 | 11 | 4 | |

| W11S -33*2500 | 270 | 28 | 33 | 2500 | 430 | 250 | 400 | 30 | 11 | 4 | |

| W11S -30*3000 | 270 | 25 | 30 | 3000 | 450 | 250 | 400 | 30 | 11 | 4 | |

| W11S -28*3500 | 270 | 23 | 28 | 3500 | 470 | 250 | 400 | 30 | 11 | 4 | |

| W11S -25*4000 | 270 | 20 | 25 | 4000 | 490 | 250 | 400 | 30 | 11 | 4 | |

| W11S -36*2500 | 320 | 30 | 36 | 2500 | 460 | 260 | 420 | 37 | 15 | 5.5 | |

| W11S -32*3000 | 320 | 28 | 32 | 3000 | 480 | 260 | 420 | 37 | 15 | 5.5 | |

| W11S -28*3500 | 320 | 25 | 28 | 3500 | 500 | 260 | 420 | 37 | 15 | 5.5 | |

| W11S -26*4000 | 320 | 22 | 26 | 4000 | 520 | 260 | 420 | 37 | 15 | 5.5 | |

| W11S -40*2500 | 380 | 35 | 39 | 2500 | 500 | 275 | 460 | 45 | 22 | 5.5 | |

| W11S -35*3000 | 380 | 32 | 35 | 3000 | 510 | 275 | 460 | 45 | 22 | 5.5 | |

| W11S -32*3500 | 380 | 28 | 32 | 3500 | 530 | 275 | 460 | 45 | 22 | 5.5 | |

| W11S -30*4000 | 380 | 25 | 30 | 4000 | 550 | 275 | 460 | 45 | 22 | 5.5 | |

| W11S -43*2500 | 430 | 40 | 43 | 2500 | 520 | 290 | 500 | 55 | 22 | 7.5 | |

| W11S -38*3000 | 430 | 35 | 38 | 3000 | 540 | 290 | 500 | 55 | 22 | 7.5 | |

| W11S -36*3500 | 430 | 30 | 36 | 3500 | 560 | 290 | 500 | 55 | 22 | 7.5 | |

| W11S -32*4000 | 430 | 28 | 32 | 4000 | 580 | 290 | 500 | 55 | 22 | 7.5 | |