1. A full range of punches and dies are available for various punching needs.

2. Quick change retaining nut system for fast punch tooling change.

3. Thoughtfully designed stripper for visibility, safety and ease of use.

PSL (WUHAN) SMART EQUIPMENT CO.LTD. |

|

Hydraulic Ironworker Machine 90T For Multiple Usage New Hydraulic High Productivity

Main features hydraulic punching & Shearing machine:

1. Structure: Steel plate welded structure

2. Mould replacement: change the die easily without adjusting the dies to reduce the mould damage rate and pipe fittings rejection rate due to the dies setting error. Skilled workers can change the mould within 10 minutes.

3. Step-less operation adjustment, hydraulic loops designed with zero load, combined with extremely low frequency oil pump motor, effectively reduced noise, increased motor efficiency and service duration.

Functions Tree,

Assemblings,

1. A full range of punches and dies are available for various punching needs.

2. Quick change retaining nut system for fast punch tooling change.

3. Thoughtfully designed stripper for visibility, safety and ease of use.

The following 9 sets of moulds and blades are installed in the machine:

1. 5 sets of round hole punching dies

2. A set of angle steel cutting blade

3. A set of square and round bar cutting blade

4. A set of flat-bar shearing blade

5. A set of notching blade.

Other moulds and blades should be ordered and paid additionally.

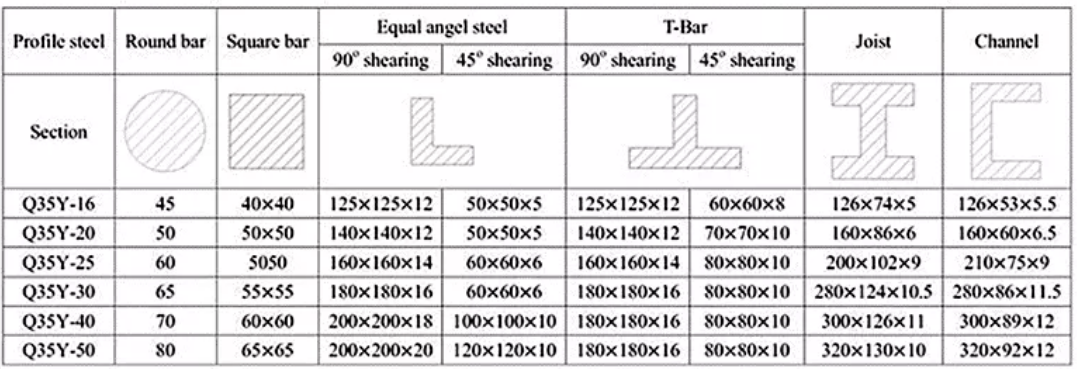

Main Technical parameters

| Model | Q35Y -16 | Q35Y -20 | Q35Y -25 | Q35Y -30 | Q35Y -40 | Q35Y -50 | |

Processing Capacity (KN) | 600 | 900 | 1200 | 1600 | 2000 | 2500 | |

Material Tensile Strength (Mpa) | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | ≤450 | |

Ram Stroke (mm) | 80 | 80 | 80 | 80 | 100 | 100 | |

Number of Stroke (times/min)(mm) | 11-20 | 12-20 | 8-18 | 6-16 | 6-16 | 6-12 | |

Throat Depth (mm) | 300 | 355 | 400 | 600 | 530 | 600 | |

| Shear Angle | 7° | 8° | 8° | 8° | 8° | 8° | |

Flat She aring | Max Shearing Capacity (thickness* width)(mm) | 16×250 | 20×330 | 25×330 | 30×335 | 40×335 | 50×300 |

| 8×400 | 10×480 | 16×600 | 20×600 | 30×600 | 30×750 | ||

Bar She aring | Square Bar (mm) | 40×40 | 50x50 | 50×50 | 55×55 | 60×60 | 65×65 |

Round Bar (mm) | 45 | 50 | 60 | 65 | 70 | 80 | |

H-beam (mm) | 100×100 | 120×120 | 175×175 | 200×200 | 250×250 | ||

C-channel (mm) | 120× 53×5.5 | 160× 63×6.5 | 200× 75×9 | 280× 86×11.5 | 300x 89x11.5 | 320x 92x12 | |

I-beam (mm) | 120× 74×5 | 160× 88×6 | 200× 75×9 | 280× 124×10.5 | 300x 130x13 | 320x 130x13 | |

| Angle Shearing | 90°shearing (mm) | 120× 120× 12 | 140× 140× 12 | 160× 160× 14 | 180× 180× 16 | 200× 200× 16 | 200× 200× 18 |

45°shearing (mm) | 60× 60×8 | 70× 70×10 | 60× 60×7 | 80× 80×8 | 80× 80×10 | 100× 100×12 | |

| Hole Punching | max diameter of punching (mm) | ф25 | ф30 | ф35 | ф38 | ф40 | ф45 |

Punching thickness (mm) | 16 | 20 | 25 | 28 | 35 | 40 | |

| Motor(KW) | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | |

Dimension (mm) | 1740× 810× 1830 | 1950× 900× 1950 | 2355× 960× 2100 | 2800× 1050× 2450 | 2900× 1110×2500 | 3200× 1440×2500 | |

| |||||||

Kinds of molds and blades