PSL (WUHAN) SMART EQUIPMENT CO.LTD. |

|

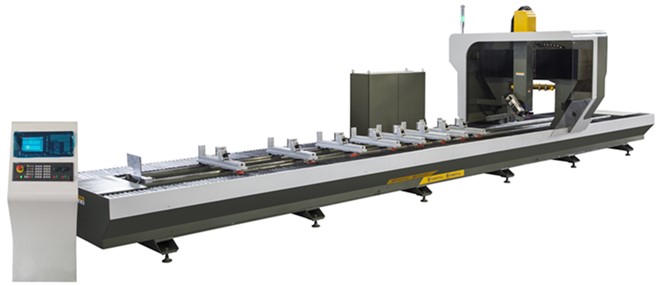

4-axis CNC Machining Center aluminum alloy profiles PVC CNC cutting drilling milling and tapping machine

Detailed Product Description:

It is suitable for milling, drilling, cutting and other processes of aluminum alloy profile, PVC, light alloy and other materials.

One time clamping can complete the processing of any angle surface of - 110 ︒ ~ + 110 ︒ with high work efficiency.

Equipped with Siemens 828d CNC system, it has fast operation, excellent performance and powerful function.

Equipped with Italian HSD high-speed motorized spindle and Siemens Servo drive.

Mobile magazine with 6/8 tool positions. The fixture can automatically identify the working position and move and clamp by itself.

HIWIN ball screw, linear guide rail, imported rack and Taiwan Air-tec pneumamtic parts are adopted.

The equipment is equipped with protective device, safety indication and fault alarm functions.

The main technical parameters:

| Type of machine | KT-S860-4 |

| Machining dimension: X-axis travel | 8500mm |

Y-axis travel (3-axes) Y-axis travel (4-axes) | 650mm 600mm |

| Z-axis travel | 500mm |

| A-axis angle range | ︒ - 110︒- +110︒ |

| Work area: X axis / Y axis / Z axis | 8500/6500/500 mm |

| Precision: Positioning | ±0.05 mm |

Repeatability X-axis Y-axis Z-axis A-axis | ±0.02 mm ±0.015 mm ±0.01 mm ±0.01 mm |

| Drilling and milling verticality | 0.1/100 mm |

| Cylindricity | 0.1 mm |

| The surface roughness of drilling and milling surface | Ra1.6 um |

| The feeding rate: X axis / Y axis / Z axis | 70/40/40 m/min |

| A-axis | 102 r/min |

| Tool change time | 8s |

| Spindle: power / speed (Italy HSD Spindler) | 7.5kw/24000 rpm |

| The servo motor (Yaskawa): X-axis / Y axis / Z axis / A-axis | 3.3/2.3/3.3/0.85/ kw |

| The drilling and milling chuck diameter | Φ16/saw blade Φ120~Φ215 mm |

| Voltage / Total power | 380V 50 HZ/20 KW |

| Overall dimensions: | 11300×2500×3200 mm |

| Control Box Dimensions: | 600×1400×1800 mm |

| The necessary power source: | 20 KVA |

| Air pressure | 6~8 kg/cm2 |

KT-S860 Basic processing capacity:

|  |  |  |  |

| Milling & slotting | Flank machining | Drilling machining | Face milling | cutting |

| Ø8 Milling knife | Ø8 Milling knife | Ø12 drilling head | Ø60 millling blade | Ø160 saw blade |

| Speed 18000r/m | Speed 15000r/m | Speed 3000r/m | Speed 10000r/m | Speed 4000r/m |

| cutting depth 4 mm | cutting width 8mm | drilling process requirement | Milling depth 3 mm | Cutting process requirement |

| Feed speed 3m/min | Feed speed 3m/min | 0.8m/min | 3m/min | 1m/min |

Equipment configuration:

1 spindle motor: 7.5KW (ATC) HSD Italy imported high-speed motorized spindle;

2 all steel structure frame: stress treatment, precision machining;

3 guide rail: X, Y, Z axis are imported linear guide rail (Taiwan HIWIN precision guide rail);

4 X, Y axis transmission: the use of imported high precision gear rack drive;

5 Z shaft transmission: imported high precision ball screw drive (Taiwan HIWIN);

6 A axis turning shaft;

6 tool position: 6 station mobile rotary tool library; Italy imported ISO30 handle; .

7 equipped with automatic tool setting device for long detector to detect tool length;

8 working table: 8 sets of automatic positioning fixture, with T type slot clamping device;

9 drive system: adopting Siemnes brushless servo drive units;

10 towline: German technology;

11 spray cooling device ;

12 Tool setting instrument: automatically detect the tool length;

13 Siemens 828D control operating system

14 3D portable controller 1 set;

15 control box: the main electrical components, industrial control, control system are all imported;

16 operating system: Siemens control system;

17 CNC system, software system Siemens