Shenzhen Sky-Win Technology Co., Ltd |

|

Verified Suppliers

|

|

The SMT Placement Process Uses Advanced Equipment To Improve The Production Efficiency And Quality Of PCB Assembly

SMT technology is important for PCB assembly because it provides high accuracy, efficiency and reliability. By using the SMT placement process, compact circuit layouts can be achieved, saving space costs, and are suitable for a wide range of package types, increasing design flexibility.

In addition, SMT reduces electromagnetic interference, improves signal integrity, optimizes thermal management, reduces failure rates, and enhances system performance. Through automated production, SMT can also reduce labor costs and has low energy consumption and environmental protection and energy saving features. In short, SMT placement process plays an important advantage in PCBA, providing key support for product usage and performance.

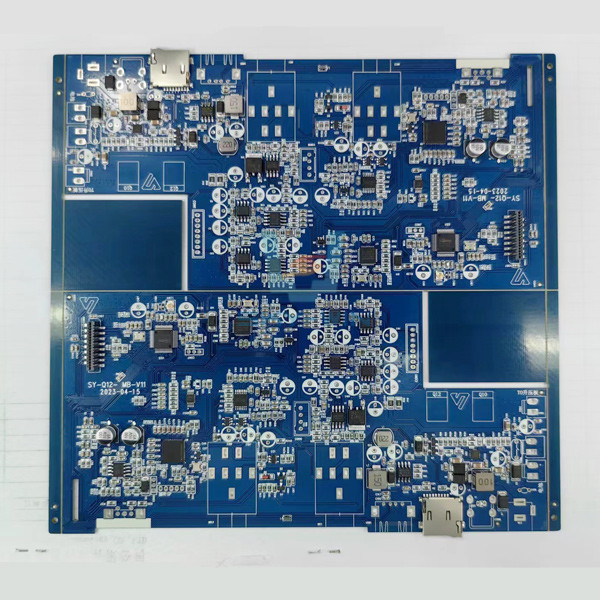

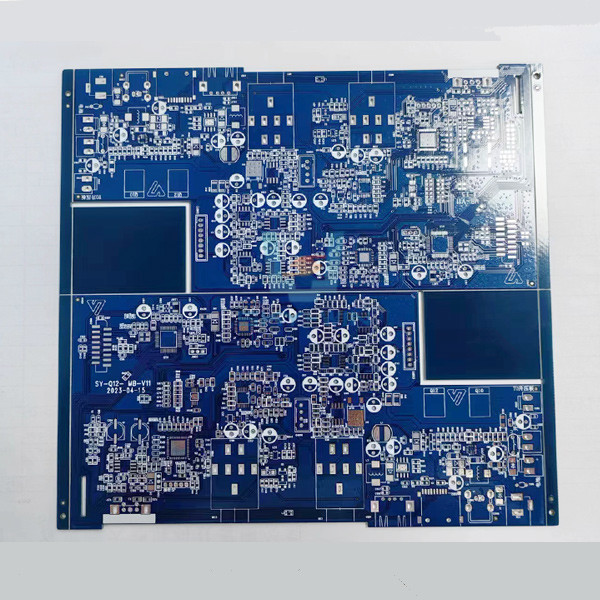

Specification of SMT PCB Assembly of Picture

| Item | SMT PCB Assembly Q12 MB |

| Material precision | 0603+QFN/QFP |

| Number of material types | 136 kinds |

| Material quantity | 446 pcs |

| PCB process | Lead-free tin spray |

| PCB layers | Single layers |

| Material of Turnkey pcb assembly | FR-4 |

| Board thickness | 1.6 mm |

Turnkey pcb assembly certification | IATF16949 /ROHS/ISO9001 |

| Application areas | portable speakers / high-power built-in sound card / card live singing / square dance speakers |

| Manufacturing process | SMT patch, AOI test, CNC panel |

Why is SMT needed to produce PCB assmbly?

PCB (Printed Circuit Board) is a key component in electronic products, used to connect and support electronic components. In the PCB assembly process, two main technologies are usually used: SMT (Surface Mount Technology) and THT (Through-Hole Technology). And the application of SMT in PCB assembly has many important advantages, the following are some of them:

As an excellent PCBA manufacturer in China, Shenzhen Sky-win offers advanced SMT services, which means we have the capability to use SMT technology for high quality PCB assembly. We can provide efficient, accurate and reliable SMT assembly services to meet our customers' needs for miniaturized, high-performance and high-reliability electronic products.