JINQIU MACHINE TOOL COMPANY |

|

Verified Suppliers

|

|

Automatic 6500KN Large Capacity electrical pole CNC Tandem Press

Brake Bending

european type press brake tool, heavy CNC tandem press brake

machine supply

Hydraulic bending machine Packing& Delivery

packing: CNC tandem press brake use steel pallet with Plastic film

or Wooden case Seaworthy

packaging for tandem

press brake

container; 40'OTx2,20'OTx2,40'HQx2.

delivery time: 70 days.

650ton CNC plate tandem press brake machine Specification

| model | 2-WE67K-650/7000 | 2-WE67K-800/7000 |

| Nominal pressure | 4000KN | 8000KN |

| length of table | 7000mmx2 | 7000x2 |

| distance between housing | 5600mm | 5600mm |

| Throat depth | 1000mm | 1250mm |

| Stroke of ram | 320mm | 320mm |

| Idle speed of ram | 70mm/s | 80mm/s |

| Working speed of ram | 7.5mm/s | 8mm/s |

| Return speed of ram | 75mm/s | 70mm/s |

| Open height | 960mm | 1250mm |

| Main motor | 30KW x2 | 55KW x2 |

| Volume of oil tank | 2100Lx2 | 2100L x2 |

| Overall size | 7150X3580X5515mm | 7220x7500x6700 |

| Weight | 6500kgx2 | 98700kgx2 |

street light pole bending machine Structure

The design of the Hydraulic tandem press brake frame is a critical

part of any machine

with relation to its ability to produce accurate parts for a long

period of time.

Totally European design,streamlined looking of our Hydraulic

tandem press brake

Taking off inner-stress of welded parts by tempering,good

stability

Remove rust with sand-blast and coated with anti-rust paint

Frames, assembly surfaces and connection holes are machined after

the welding process,

up to 60' in a single pass.

single press brake equipment:

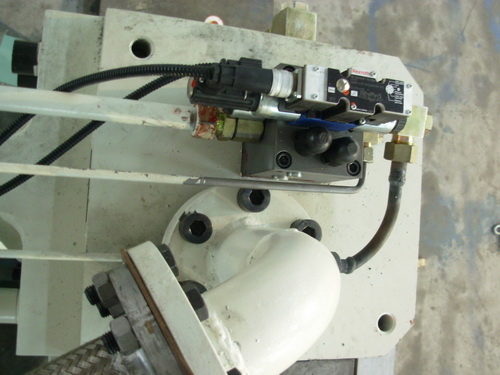

12 meter CNC press brake machine Hydraulic system

1. Adopt integrated hydraulic control system, more reliable and

easy for maintenance.

Hydraulic system is from Bosch – Rexroth,Germany.

2. Hydraulic tandem press brake all seals in cylinder is PARKER

from USA,the most famous

brandgood quality and high performance

3. Overload overflow protection is outfitted to hydraulic

system,which can assure no leakage,

and the oil level can be read or seen directly.

4. The hydraulic system is made in compliance with current

regulations (Directive 98/37 EC).

1000ton capacity sheet bending machine with servo proportional

vlave:

CNC control system for hydraulic press brake:

The compact DA-65W is a complete CNC solution for conventional as

well as synchronised

press brakes for this Hydraulic tandem press brake.

The panel based control, capable of controlling up to 4 axes, can

be integrated in cabinets

as well as in an optional pendulant arm housing.

Equipped with the Delem user-friendly user interface, the

DA-65W provides all main

Hydraulic tandem press brake functionality.

The unique ‘hotkey’ navigation gives direct access to the

programs in memory and enables

quick and easy programming of a product. All common bend parameters

are located on one

page. For advanced parameters an additional page can be

selected.

Angle programming of the Y-axis, crowning function and pressure

control are standard on

board.

USB interfacing enables the use of memory sticks as a fast product

and tool backup medium.

Electrical System for homemade press brake machine:

Electrical components are imported or from Sino-foreign joint

Venture,in accordance with

international standards, reliable safety,long life,good

anti-interference ability,a radiation unit

is fitted in electrical cabinet.

Protective fence and the safety interlock to ensure the operation

safety. Have a movable

single-hand pedal switch,easy to operate.

The Hydraulic tandem press brake by the European Union CE

certification and ISO quality

system certification.

press brake suplier design the new type electrical system;

Performance Charateristics for press brake bending

1. advance configuration, high precision and high effciency CNC

tandem press brake

2. all major elecetrical and hydraulic elements are assembled

with high grade inter-national

brands holistic welding structure treated by annealing.

3. standard configuration with 4+1 axes.

4. equipped with world-calss mechnical crowning system is

controlled by CNC system.

5. all Major electrical and hydraulic elements are assembled with

high grad international

brands.front support arms provide

6. a set of upper punching and bottom die is provided with the

machine.

here is a catalog of CNC tandem press brake

CNC multi machine tandem hydraulic press brake.pdf

BOSCH-Rexroth hydraulic system for CNC multi tandem press brake machinery: