TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

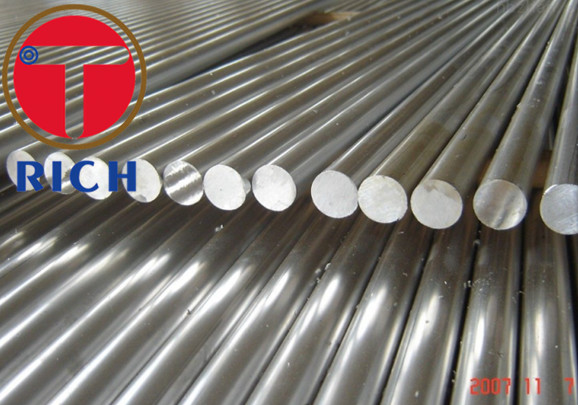

ASTM A321 Hot-rolled,quenched,and Tempered Carbon Steel Bars

6.35-241.3mm Out Diameter![]()

2.Manufacture

1)Melting Practice The steel shall be made by one ormore of the following primary processes: open-hearth, basic-oxygen, or electric-furnace. The primary melting may incor-porate separate degassing or refining and may be followed bysecondary melting using electroslag remelting or vacuum arcremelting. Where secondary melting is employed, the heatshall be defined as all of the ingots remelted from a singleprimary heat.

2)Discard -A sufficient discard shall be made (from eachingot, when ingot cast) to secure freedom from injurious pipingand undue segregation.

3)Heat Treatment:

Cooling -Immediately after rolling, the bars shall beallowed to cool to a temperature below the critical range undersuitable conditions to prevent injury by too rapid cooling.

Quenching and Tempering -The material shall beuniformly heated to the austenitizing temperature, soaked for asufficient length of time to produce the desired change instructure (a group thus heated being known as a quenchingcharge), and quenched in some medium under substantiallyuniform conditions for each quenching charge. The materialshall then be uniformly reheated to the proper temperature fortempering (a group thus reheated being known as a temperingcharge), and allowed to cool uniformly. The temperatureselected for tempering shall not be less than 800F (427C).

Stress Relieving -When it is desirable to minimizeinternal stresses introduced by straightening, the purchasermay specify a stress relief anneal as a final operation.

3.Mechanical Properties

1)Tensile Properties -The material, after final heat treat-ment and straightening, shall conform to the requirements as totensile properties specified in Table 2.

2)Test Specimens: .

Test specimens shall be prepared for testing from thematerial in the quenched and tempered condition.

Specimens shall be taken longitudinally and may betested in full

thickness or section, or they may be machined tothe dimensions

shown in Figs.4 or Figs.6 of Test Methods andDefinitions A 370. If

test specimens are selected conforming tothe dimensions of Fig.6

for sizes 1'/ in. (38.1 mm) and largerin diameter or distance

between parallel faces, they shall bemachined from a position

midway between the center and the surface of the bar. If test

specimens are selected conforming tothe dimensions of Fig.6 for

sizes under 1'/h in. in diameter ordistance between parallel faces,

they shall be machined fromthe center of the bar.

3)Number of Tests One tension test shall be made fromeach tempering

or stress-relieving charge. If more than onequenching charge is

represented, one tension test shall be madefrom each quenching

charge. If more than one heat is repre-sented in a quenching

charge, one tension test shall be madefrom each heat and size. For

continuous type of treatment, onetension test shall be made for

each 25 tons (23 Mg) of each heator size.

4)Test Methods- Tension tests shall be made in accor-dance with

Test Methods and Definitions A 370. The yieldpoint shall be

determined by the drop of the beam or halt in thegage of the

testing machine, or by the use of dividers, ascovered in Section 12

of Test Methods and Definitions A 370.

Outside diameter and wall thickness allow deviation mm

| sort code | Manufacturing method | Steel tube size | Allowable deviation | |

| WHR (WHEX) | Hot rolled(extruded)steel tube | OD | all | ±1%Dor±0.50(choose the bigger) |

| WT | ≤20 | -15% +0.45 -10%S or –0.30 (choose the bigger) | ||

| >20 | ±10%S | |||

| WHE | Heat expand steel tube | OD | all | ±1%D |

| WT | all | ±15%S | ||

| WCD (WCR) | Cold drawn(rolled) steel tube | OD | ≤30 | ±0.20 |

| 30<D≤50 | ±0.30 | |||

| >50 | ±0.8%D | |||

| WT | 1.5≤S≤3 | +12.5% -10% S | ||

| >3 | ±10%S | |||

Bending of steel tube per meter

| OD/mm | Bending per meter(mm/m) |

| ≤15 | ≤1.5 |

| >15~30 | ≤2.0 |

| >30 or D≥351 | ≤3.0 |

3.Torich Strength:

1. Torich is the STEEL TUBE MAKER company in China,playing a

significant role in domestic market as well as international

market.

2. Our products have exported to over 56 countries worldwide,

winning a great fame among our customers.

3. There was no quality claim in the past 3 years.

4. First production was started since 1997, our boss worked in

steel tube industry for over 10 years before started the own

factory, factory engineers with over 30 years manufacturing

experience, knowing well about production and inspection

technology.

5. We have been exporting steel tubes since 10 years ago, and know

well about international standard for steel tubes

DIN/EN,ASTM,SAE,BS,GOST,JIS etc,also with great experience of

International trading practices.

6. Our team take Timely action within 24 hours after receiving

customers' first requirement and enquiry.

7. 100% prompt delivery in the past 3 years.

8. 100% dimensional check and 100% visual inspection on tube

surfaces.

9. 100% eddy current test and ultrasonic test for detecting

longitudinal and transversal defects.

10.Convenient tranportation: production location is 30 mins high

speed train from Shanghai, 2 hours drive from Shanghai

![]()

How to get the sample?

1.You are requested to pay for sample charges and courier charges

from China to your country; and the free sample is according the

product like size, steel grade and quantity, please consult our

sales for details

2.Sample charges will be refunded when order is placed.

What is your Payment Term?

1.T/T: 30% deposit in advance, the balance 70% paid before shipment

2.30% down payment, the balance 70% paid against L/C at sight

3.Upon negotiation

Who are your customers?

1.Stockists, Distributors,Wholesalors,Agents, Traders, End Users,

etc

How long will you react on our requirement?

1.Your requirement would be treated within 24 hours on weekdays.

Quotations would be sent upon technical details confirmed by

customer!

Any more questions about your doubts, please feel free to send us

your emails or call!