NTT Mould Co., Ltd. |

|

Custom Made Injection Mould Plastic Parts PC Mould For Household Battery Cover

| Part Name | Battery Cover |

| Part Number | NTT-263-54-2 |

| Drawing Number | 69-1540-2 |

| Material | PC |

| No. of Cavities | 2 |

| Mold standard | 1.2344 |

| Injection System | Cold runner |

| Shrinkage | 1.006 |

| Mold Size | 270x280x251 mm |

| Sample Color | Black |

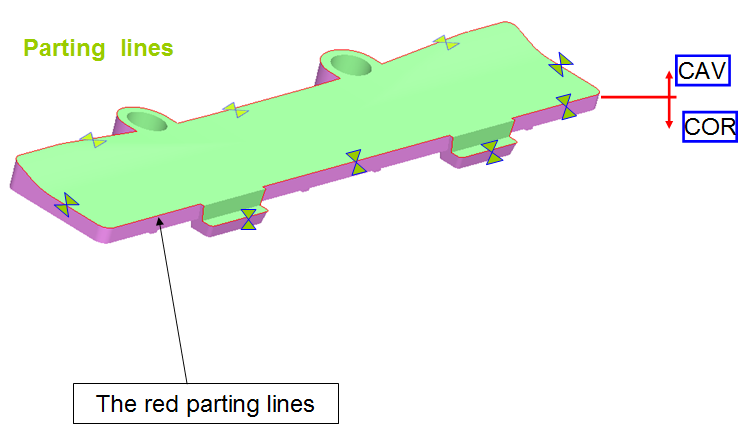

Mold Rough Idea:

Specifications:

| Shaping Mode | Plastic Moulding part & injection parts |

| Production Equipment | Elite Plastic Injection Machines ,CNC, Mirror EDM machine, Wire

Cutting machine, Carving machine, Lathe Drilling machine, Grinding machine, Milling machine, |

| Material steel | P20, 738, 738H, 718, 718H, NAK80, S136, S136H, 2378H, 2311, 2083,

2316, H13, SKD61, 2344, 8407 And other material as requirement |

| Part material | ABS, PP,PC, POM ,PVC, PE, PET, PMMA , Acrylic, and other material As requirement |

| QC Machine | 3D Measurement, Profile Projector, Hardness Tester and other regular size inspection equipment. |

| Mold Cavity | Single or Multi-Cavities Available |

| Runner System | Cold or Hot-Runner Available(Hasco, yudo, d-m-e etc.) |

| Mould Base | LKM, HASCO, DME etc |

| Hardness of steel | Vacuum quenching ,Nitride, HRC41-47, HRC46-50,HRC60 |

| Standard mould parts | Dme, hasco, JIS, cumsa etc. |

| Mold Lead time | 4 Weeks T1 samples , exact time depends on Mould Complexity |

| Mould Life | 0.3 Million Shots- 1Million shots (Different steel different production, min mold life 200, 000 shots) |

| Packing | Exporting standard |

Our business scope:

1. Plastic mould design & fabrication

2. Injection moulding

3. Secondary operation

Project management flow:

| Business Step | |

| 1. R&D | We support customer R&D. |

| 2. Quotation Making | Mould Quotation will be finished in 1 day according to information we get |

| 3. Negotiation | The quality ,price ,material, delivery time .payment item. ect |

| 4. Mould Design | 3-5 days for mould and product 3D/2D drawing design |

| 5. Mould | According to customers' request to build the mould. Before make the mould .We make final design to customer approval first . Mould will be usually finished in 25-60 days |

| 6. Mould Testing | When moulds are finished,we will trial the moulds to check if it satisfy custmers' needs. And we will send samples for consumers' approvement. |

| 7. Sample confirm | If the first sample come out is not satisfied.we modify the mould until meet customers's requirements. |

| 8. Delivery | Delivery goods by sea or by air ,according customers requirement |

Our product range:

1. Automobile mold & parts

2. Electricals mold & parts

3. Communications mold & parts

4. Double color mold & parts

5. Clear parts & mold

6. Precision parts & mold

Our advandage:

1. Professional manufacturer

2. Certificates: ISO 9001:2008

3. Highly skilled manufacturing process

4. A variety of ODM&OEM product range

5. Strict quality Control System

6. Advanced equipment and excellent R&D Team

7. Software for specification drawings: Pro/E, Auto CAD, solid work

2001,CAXA,UG,CAD,CAM