NTT Mould Co., Ltd. |

|

Black Plastic Cover Mould Display Rahmen Frame A B Plate P20 Core Cold Sprue

Project Infomation:

| Mold Number | NTT-252-47 |

| Part Name | DISPLAY RAHMEN |

| Part No. | / |

| No. of Cavities | 1 |

| Core and Cavity | 1.2344 |

| A,B Plate Material | P20 |

| Exported or Not | Exported |

| Injection System | cold sprue / tunnel gate |

| Mould Life | 1,000,000 Cycles. |

| Resin | PC-ABS |

| Color of Part | Black |

| Tool Dimensions | 330x400x320 mm |

| Tool Weight | 400 kg |

| Mold Lead Time | 5.5 weeks |

Q & A :

◆ What do you need for quotation?

We need product 2D drawing or 3D file or specific sample with

detailed explanation;

need to know the materials request for product or mold, also expected mold service life.

◆ What’s the percentage of automobile molds you made, what’s the

brands?

About 40% of total molds are for automobile.TOYOTA, HONDA, JAGUAR,

BMW and BUICK.

◆ How about the largest mold you ever made?

1400mm*1100mm*1000mm and 10 tons

◆ How about the tolerance?

Mold tolerance 0.005 mm, Product tolerance 0.02 mm

◆ Have you ever made over mold? What kind of materials you use?

We have good experience in over mold of

ABS+PC,PA+TPE,ABS+TPE,TPE+TPE.

◆ How about the steel you usually use?

We only use raw materials with good quality and origin certificate.

We use steel of P20, P20H, 718H, NAK80, 1.2311, H13, 1.2344, 420SS,

S136, S-7 and 1.2767.

They are all from famous suppliers, such as LKM, ASSAB, THYSSEN and DAIDO.

◆ How many molds could you make every month?

35-40 SETS

◆ How about the standard components you use?

We only use standard components from brand supplier like LKM,

DAIDO, HASCO, DME.

◆ How long do you need for quotation?

Exact quotation will be available within 2-3 working days once we

get sufficient information.

Product Presentation:

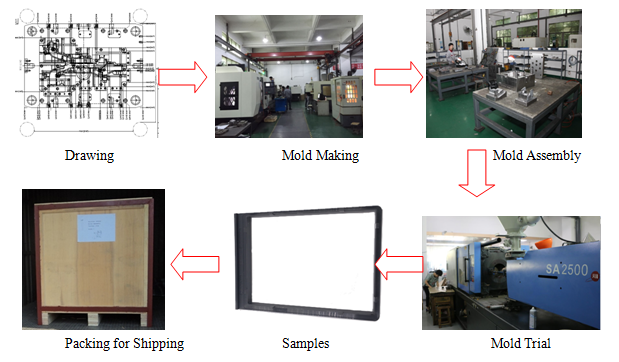

Order Processes

◆ RFQ Quotation ======= ◆ POn ======= ◆ DFM ======= ◆ Mold Design

◆ Design Approved ======= ◆ Steel Ordering =======◆ Machining

◆ Mold Trial ========◆ Sample Approved =======◆ Texture =======◆

Delivery

More Part Information:

Quality provided

Our quality team is strictly complying with ISO system procedure to

control each of stages process. If our customers have any special

requirement, our engineer team will consult with you priority to

fix agreement specification to ensure product tolerance meet you.

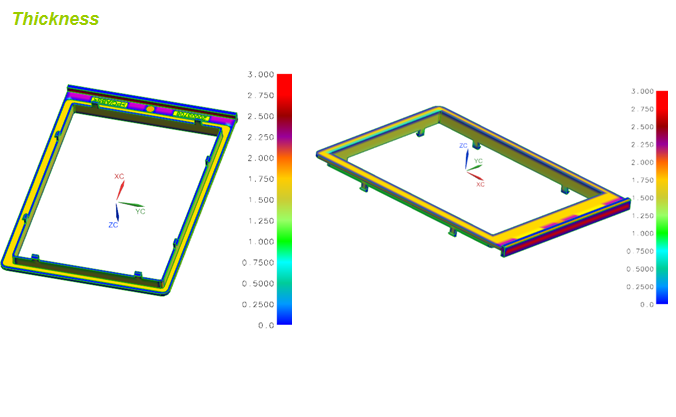

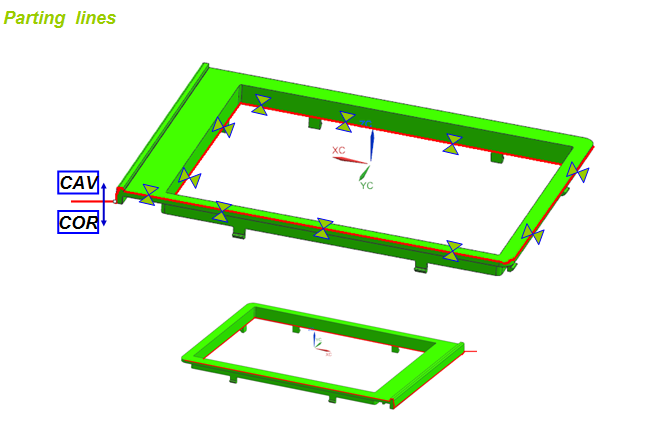

Mould Engineering

Our engineers uses DFM/PFM for all of parts from molds to production, the molds design we will usually uses Mold flow simulation review, from mold base, steel, electrode, runner system the whole process inspection and report. Especially, the mold base, steel, runner system we asked details certificated before machining, during machining, our engineer is strictly check the process to ensure each of stages parts perfect.

Our quality team is strictly complying with ISO system procedure to control each of stages process. If our customers have any special requirement, our engineer team will consult with you priority to fix agreement specification to ensure product tolerance meet you.

If you have any questions, pls go ahead and contacts us, we are very pleased to show our price to you. Hope to hear from you soon. Thank you!