NTT Mould Co., Ltd. |

|

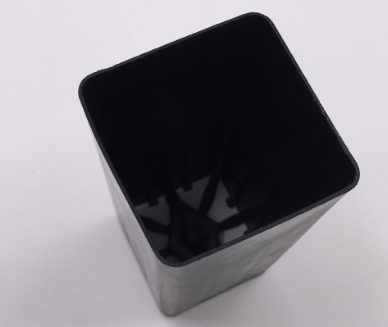

YUDO Hot Runner Injection Molding Plastic Tube Mould With P20 / LKM

Custom-Made Plastic Injection Parts Tube Mould with P20 , LKM , YUDO

Specifications:

Tool Dimension: 250x250x390mm

Tool Weight: 191kg

Mold Standard: LKM or equal (Moldbase steel S50C)

Material and Hardness: P20

Injection System: 1 hot drops (Yudo)

Mould Life (Cycles): 300000

Mould Lead Time: 4.5 weeks

What NTT serve?

1. High quality & precision injection molds. Hot runner mold, over mold, two-shot mold, unscrewing mold, multi-cavity mold, etc.

2. Injection molding, part assemblies

3. Value-adding services: Die casting, Painting, Pad-printing, Silk-Screen Printing, Hot Stamping, Plating, Ultrasonic Welding, Automation.

4. Industries: Automotive, electronics, home & office appliances, medical, etc

5. Markets: 90% molds are exported to North America, South American, Europe and Australia.

Project management flow:

| Business Step | |

| 1. R&D | We support customer R&D. |

| 2. Quotation Making | Mould Quotation will be finished in 1 day according to information we get |

| 3. Negotiation | The quality ,price ,material, delivery time .payment item. ect |

| 4. Mould Design | 3-5 days for mould and product 3D/2D drawing design |

| 5. Mould | According to customers' request to build the mould. Before make the mould .We make final design to customer approval first . Mould will be usually finished in 25-60 days |

| 6. Mould Testing | When moulds are finished,we will trial the moulds to check if it satisfy custmers' needs. And we will send samples for consumers' approvement. |

| 7. Sample confirm | If the first sample come out is not satisfied.we modify the mould until meet customers's requirements. |

| 8. Delivery | Delivery goods by sea or by air ,according customers requirement |

Our advandage:

1. Professional manufacturer

2. Certificates: ISO 9001:2008

3. Highly skilled manufacturing process

4. A variety of ODM&OEM product range

5. Strict quality Control System

6. Advanced equipment and excellent R&D Team

7. Software for specification drawings: Pro/E, Auto CAD, solid work

2001,CAXA,UG,CAD,CAM

Product Pictures:

Your visiting are warmly welcome anytime!