Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

Upon confirmation of your order, a comprehensive Design for Manufacturing (DFM) review is

conducted to identify any potential issues that could impact the quality of your parts.

All incoming materials undergo thorough inspection and verification using a suite of testing

equipment. Final inspection reports are generated before shipment.

Additionally, we offer real-time sharing of inspection data, fostering collaboration to address any

quality concerns that may arise during production.

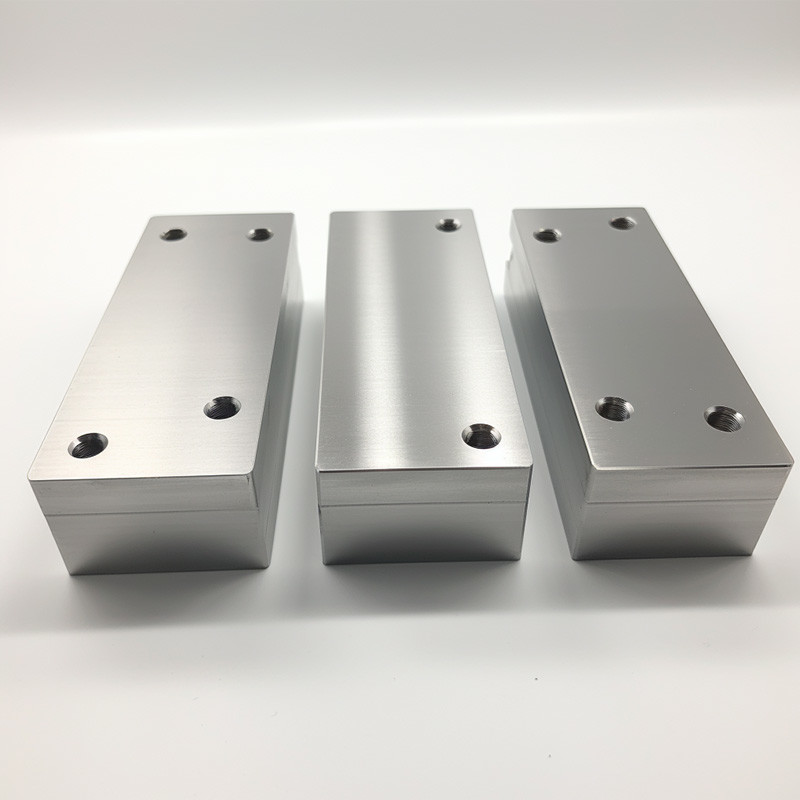

Product Details

Stainless steel is highly resistant to corrosion and rust, making it suitable for situations

where a part may be exposed to the elements for a long period of time. Stainless steel is also

fairly malleable and ductile.

| Common Stainless Steel Materials | |

| No. | Properties |

| Stainless steel 304/304L | Stainless steel 304L (CNC) has excellent mechanical properties and good machinability. Resistant to most environments and corrosive media. |

| Stainless steel 316/316L | Stainless steel 316L (CNC) has similar mechanical properties to 304, with higher corrosion and chemical resistance. Ideal for marine applications. |

| Stainless steel 303 | Stainless steel 303 (CNC) has excellent toughness, but lower corrosion resistance than 304. Ideal for high volumes, due to its excellent machinability. |

| Stainless Steel 17-4 PH | Stainless steel 17-4 (CNC) - SAE grade 630 - is a precipitation hardening alloy with good corrosion resistance. Can be hardened up to 44 HRC. |

| Stainless steel 416 | Stainless steel 416 is magnetic and has a high machinability. |

| Stainless steel 2205 Duplex | Stainless steel 2205 Duplex (CNC) is the alloy with the highest strength and hardness. Suitable for applications in severe environments up to 300°C. |

| Stainless steel 420 | Stainless steel 420 provides high strength and corrosion resistance. It is the hardest of all stainless steels when hardened. |

| Stainless steel 440C | Stainless steel 440C has improved toughness and corrosion resistance due to Carbon and Chromium content. |

| Stainless steel 430 | Stainless steel 430 is magnetic and corrosion resistant. |

| Stainless steel 301 | Stainless steel 301 is corrosion resistant similar to Stainless steel 304. |

| Stainless steel 15-5 | Stainless steel 15-5 has a higher toughness than 17-4, better corrosion resistance and transverse properties compared to other similar martensitic grades. |

Stainless Steel Finishing and Post-Processing

The finish of stainless steel can vary significantly depending on the surface roughness.

However, it is typically described as shinier compared to unfinished aluminum alloys,

and it tends to have a slightly darker and more silver color.

Stainless steel offers flexibility in achieving various surface finishes, including options such as

media blasting, sanding, hand-polishing, and powder coating.

These processes can be employed to achieve a wide range of surface finish textures and

appearances.

| Name | Machining Marks |

| Brushed + electropolishing | Removed on Primary surfaces |

| Electroless nickel plating | Reduced but visible |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

| Black oxide | Visible |

CNC Machining Applications

CNC milling, characterized by its efficiency, precision, and automation, is a transformative force

across various industries. Machine shops, serving as crucial entities in the manufacturing process,

provide essential services for prototypes and full production runs.

The electronics industry relies extensively on CNC machines for crafting components such as

electronic enclosures and circuit supports. In the commercial sector, CNC cutting heads play a key

role in producing cost-effective parts, streamlining production processes.

The oil and gas industry utilizes CNC machines for the fabrication of drill bits, cylinders, pins, rods,

valves, and more. The medical industry benefits from CNC milling in the production of diverse

components, including implants, surgical equipment, and medical devices.

Lastly, the aerospace industry demonstrates a constant demand for CNC machined parts,

employing this technology to create intricate, customized components vital for aerospace equipment.

Company Profile

FAQ's

1. What are the advantages of CNC machining?

CNC machining offers a spectrum of advantages, prominently featuring rapid prototyping and the

expedited production of full-scale parts. Its hallmark is the ability to achieve exceptional precision

and accuracy in manufacturing, catering to tight tolerances for CNC parts of diverse sizes.

This method stands out for its flexibility, influencing factors such as volume, pricing, lead times,

and the array of materials and finishes available.

2. What are standard machining tolerances?

Standard machining tolerances are set at ± 0.005" or 0.13mm, delineating the acceptable range

for dimensions. For example, if a CNC machining tool carries a tolerance of ± 0.01 mm, it signifies

a permissible deviation of 0.01 mm in each cutting operation.

Leveraging a provided drawing, our CNC machining service can attain part tolerances as precise

as ± 0.0002 in. In cases where no drawing is available, all CNC parts adhere to our ISO 2768

medium standard. Projects requiring even tighter tolerances, such as ±0.025mm or ±0.001",

can be accommodated with an engineering drawing specifying critical features.

3. How does you ensure the quality of my parts?

After order confirmation, we conduct a thorough Design for Manufacturing (DFM) review to pinpoint

any potential issues that could affect part quality. Incoming materials undergo rigorous inspection

and verification using advanced testing equipment.

Final inspection reports are generated before shipment. Moreover, we provide the capability to share

inspection data in real-time, allowing us to collaborate on addressing any quality concerns that may

arise during the production process.