Zhangjiagang Chiyu Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

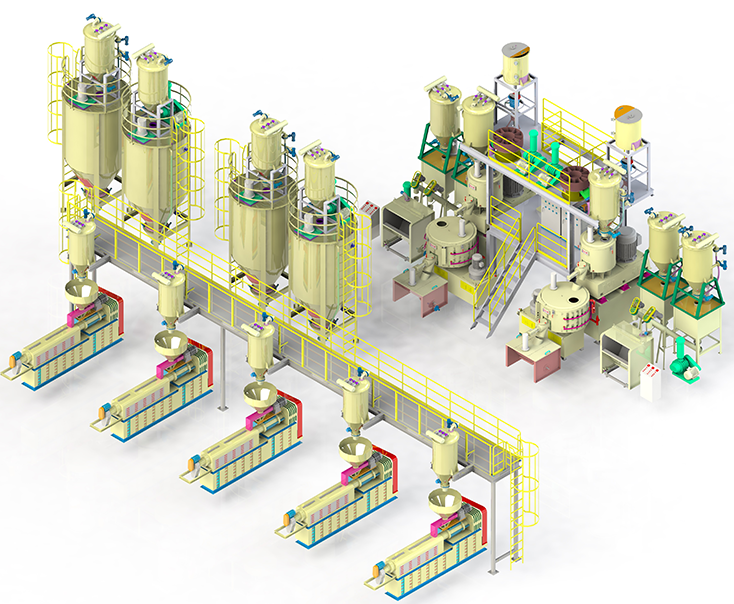

Auto pneumatic vacuum feeding conveying systems for PVC extruder

Auto pneumatic vacuum feeding conveying systems are best employed

where the product is to be conveyed from several feeding points to

one delivery point. Product channelling is extremely simple and

dust-free since there is no excess pressure Vacuum unit and dust

collector.

The system is designed for the automatic feeding of multiple

extruders. The storage and transportation of PVC compound are

carried out in closed stainless steel containers and pipes. Some

dust removal system are taken to effectively prevent dust pollution

and keep the workshop clean. The control system is controlled by

Siemens PLC, and the main electrical components are imported famous

brand products to ensure the long-term, reliable and efficient

operation of the whole system. The control system can automatically

or semi automatically complete the whole feeding process.

The simulation screen can display the operation status of each part of the system in real time through the indicator light, and can flash the alarm for the failure part to attract the attention of the operator. The extruder adopts the combination of pneumatic vacuum feeding conveying and screw feeding. The silo is equipped with two level meters. When the lower level meter shows that there is a lack of material, the feeder will work automatically to fill the material in the large silo to the small silo. When the upper level meter shows that the material is full, the feeder will stop working and temporarily stop feeding. In order to ensure the normal and continuous operation of the extruder, a 50L small hopper is added above the extruder and a level gauge is equipped respectively. If any one of the six level meters shows a lack of material, the screw feeder will automatically start to work and start feeding until all the six level gauges light up to show that the material is full, and the screw feeder will stop working; if one level meter is short of material, the screw feeder will start working again, The whole feeding process runs automatically under the control of PLC.

| NamePneumatic comveying system | Pneumatic comveying system |

| Used for | food,Chemical,rubber |

| Material | Powder,Pellet |

| Capacity | 800-2500Kg/h |

| Powder,Pellet | Siemens 1200+Wincc |

| Inverter | ABB |

Using Scope

PVC Door and Windows Profiles

PVC Drainpipes

PVC Cable Channel

PVC Cable

PVC Waste and Clean Water Pipes

PVC İrrigation Hoses

PVC Water Isolation Materials

PVC Floor Covering

PVC Folio

PVC Canvas

Wood Composite Panel (WPC)

Metallic Powder Coating (Bonding Mixer)