Hebei Huanzhou Technology Co., Ltd |

|

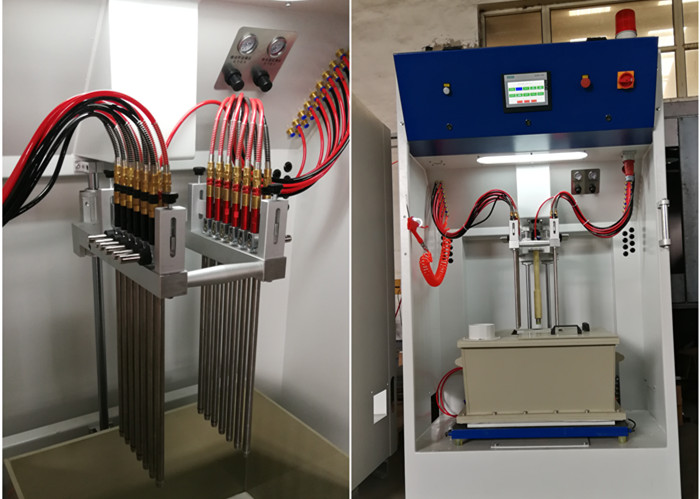

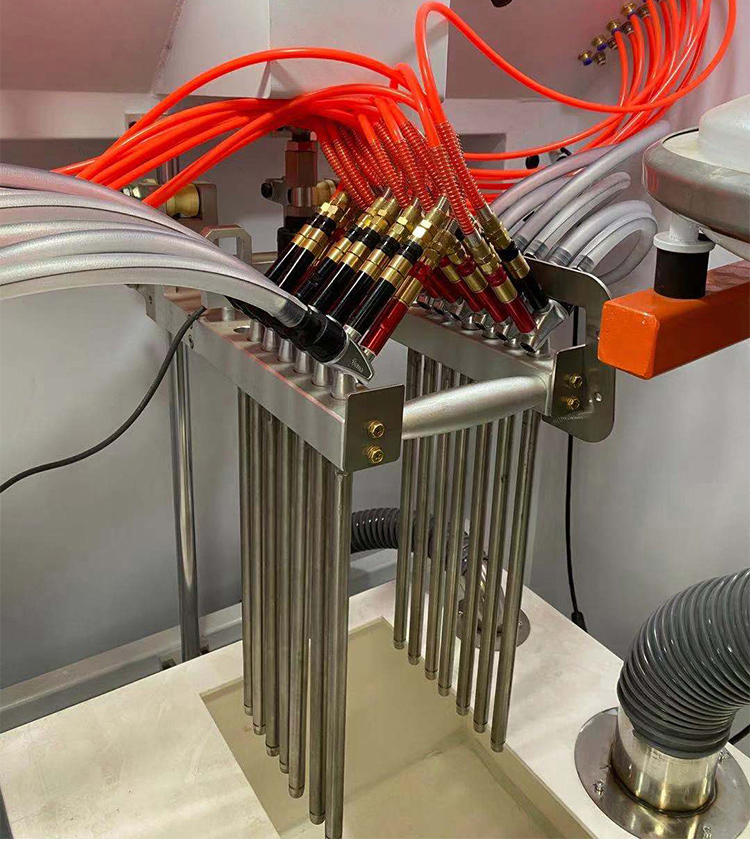

The powder supply center uses clean and dry compressed air to transport the powder to the powder automatic spray gun. At the same time, the

recovered powder is transported back to the powder box of the worship center. At the same time, the control panel can be used to control the

powder booth, spraying line chain, elevator, powder recovery fan and other equipment.

Machine Type | Painting Equipment |

Product name | Electronic Powder Coating Machine |

Application | Powder Coating Spray Application |

Name | Electrostatic Powder Coating Spray Machine |

Usage | Powder Coating Workpieces |

Technology | Electrostatic Powder Spraying Technology |

Keywords | Manual Electrostatic Powder Spray Coating Machine |

Advantage | High Efficiency Low Cost |

Color | Metal color |

Kinds of coating | Automatic Powder Coating |

NO. | Item | Specifications |

1 | Main function | Fast powder clean and change |

2 | Input voltage | ~220V 50-60Hz |

3 | Capacity of powder bucket | 50kg |

4 | Air blower model | 4-72No.2.8A |

5 | Motor power | 1.5KW |

6 | Vibrator sieve mesh | Sieve mesh number 40 |

7 | Vibrator model | QZ |

8 | Control | PLC control with touch screen |

1. all of our PLC control system and touch screen we use Siemens brand series.

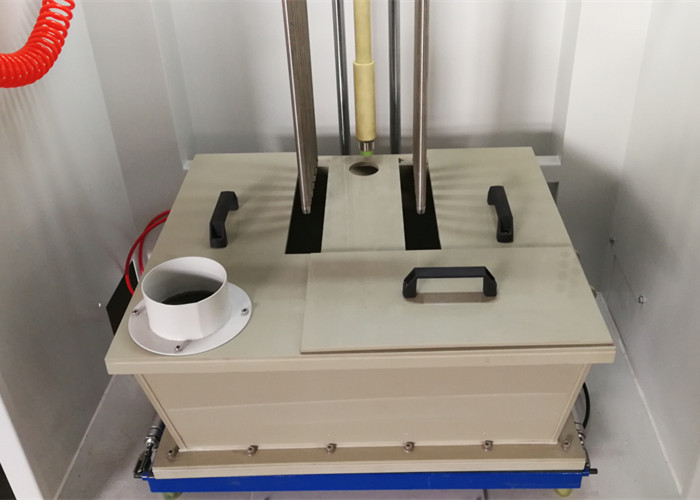

2. There is powder coating tracking and inspection position system. The position of the powder suction tube will go down as the powder decreases, which always keep suction tube position at upper powder level, you know the upper position of powder have better fluidized effect , and to make powder spray more evenly and to meet high and strict painting layer product.

3. There is alarm system when no powder in the powder tank,the alarm will remind you add powder.

4. you can find at bottom of the powder tank, we have vibrating function on the bottom of the powder tank ,which can make powder fluidized effect more better.

5. There is automatic clean function,automatic clean the auto guns, and self clean for the powder supply center. It can make cleaning work very easy.

When you use our powder supply center, you can make painting work easy and comfortable.

Guarantee and after-sale service

The guarantee period of machinery is 12 months after shipping. The

buyer should follow the operation instruction and maintenance

instruction provided by the seller. Within the guarantee time, the

buyer should be responsible for quality problem of the equipment

except for man-made damage or problem caused by wrong operation.

After guarantee period, the seller will provide necessary support

on the customer’s demand and charge reasonablely based on material

cost.

Is it safe to order from you?

Yes,100% sure you are safe to order from us. We exported to 30 countries and we are the famous factory produce powder coating equipment more than 20 years in China.

How to delivery?

By sea for big order ,by courier for small order ,by airlines.

How to pay?

We accept the paypal ( but credit card not accepted),Western Union ,Bank transfer , money gram,etc.

Which model should I choose?

When spray specially metallic powders, according to your product shapes and the coating job details. For example, need to change colors often or only few colors, then choose the box feed unit or hopper feed unit. The small hopper unit is good for lab test or small work.

Can I customized the machines?

Yes, we are a professional team for powder coating equipments, Our

technician will design for you specially according to your needs

and your factory, workpiece etc information.

What should I offer if I want to customized the machine?

a. Your factory available for the equipment dimension by L x W x H

b. Your max workpiece or product weight and size by L x W x H

c. Your product surface condiation(with oil or dust?) and some

pictures if possible

d. Your output capacity(for machine line)

e. Your industrial electric power in V-Phase-Hz.

Can you install for us?

Yes, we can install overseas for you. But the engineers overseas

installation cost, round trip air tickets, accommodation, meals and

transport charges are on the buyers.