Shanghai Shengli Machinery Manufacture Co., Ltd. |

|

Horizontal Double Paddle Mixer / Paint Blender With 10rpm-100rpm Speed

General introduction:

Horizonal twin shafts paddle mixer, double shafts mixer, paddle mixer, paddle blender, paint blender.

Twin shaft mixer is widely applied in chemical, biological,

and construction material.

It can mix powder, granule, and fiber especially in battery,

construction, environmental, mineral and agricultural line. cement

mixer, fiber cement mixer etc.

Product features:

With the most powerful motor, material can be mixed evenly in the

shortest time.

It is particularly good at mixing material with big difference in

gravity, mesh size, fluidity Data table

Data table

| specification | WZL-0.3 | WZL-0.5 | WZL-1 | WZL-2 | WZL-3 | WZL-4 | WZL-6 | WZL-10 | WZL-15 | WZL-20 |

| working capacity(m³) | 0.18 | 0.3 | 0.6 | 1.2 | 1.8 | 2.4 | 3.6 | 6 | 9 | 12 |

| working capacity(kg) | 200 | 300 | 600 | 1200 | 1800 | 2500 | 3600 | 6000 | 9000 | 12000 |

| speed(RPM) | 60 | 60 | 53 | 43 | 43 | 35 | 35 | 29 | 22 | 18 |

| power(KW) | 5.5 | 7.5 | 11 | 22 | 30 | 37 | 44 | 60 | 90 | 150 |

| weight | 650 | 900 | 1300 | 2300 | 2800 | 3400 | 5000 | 6000 | 8500 | 12000 |

| length | 1600 | 1800 | 2400 | 2800 | 3200 | 3400 | 3700 | 4000 | 4600 | 5200 |

| width | 850 | 1000 | 1400 | 1700 | 1950 | 2000 | 2200 | 2600 | 3100 | 3500 |

| height | 950 | 1100 | 1800 | 1950 | 2000 | 2000 | 2300 | 2600 | 2800 | 3000 |

CHARACTERISTIC:

Mixing powder to powder, particle to particle or particle to powder, and liquid can spay into material, but all material must be solid powder during all the process.

The two axes rotate at the same speed in different direction which can mix material uniformly with 1:1000 proportion or with great difference of density.

When mixing, by suffering great power of interaction, it will cause material destroyed at very small scope.

When mixing, the materials are moving at enormous energy, double shaft with so many paddles it will request the machine must have enough power.

The gap between the paddle and cylinder wall is 3~5mm, so to enforce the mixing effect and reduce the leftover after discharge,

WORKING PRINCIPLE:

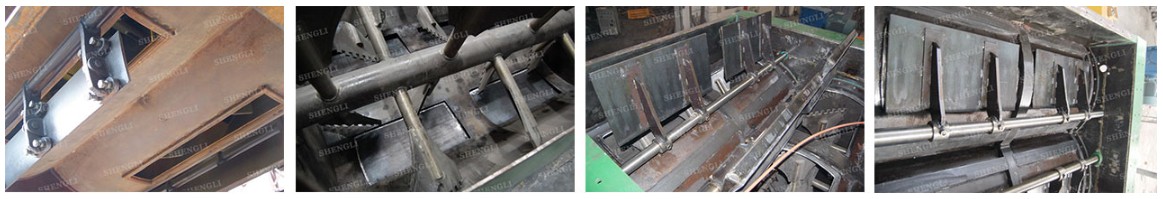

In the horizontal twin ”U” container, there are two opposite

rotation axes and certain numbers of paddle stirrers set up on the

each axe at certain angles.

When mixing:

The horizontal axes make the material move up and down.

Rotation at opposition direction of the double axes makes materials exchange from left to right.

Paddle stirrers push material at angle 45 to move circularly in the cylinder, and the materials can reach good mixing effect under the movement of radial and axial orientation

Material can be carbon steel, manganese steel, ss304, 316L and 321;

besides, different material can also be used in combination between

the part contact with the raw material and the parts don’t contact

with the raw material.

Surface treatment for stainless steel include sandblasting,

wiredrawing, polishing, mirror polishing, all can be used in

different parts of a mixer

2. Reliable driven unit

The driven unit, power and speed are varied according to different

raw material, starting method, and processing.

Because of the meshing relationship for the paddles, the double

shaft driven unit is required to be equipped with synchronous

ability.

The four different driven combination launched by Shengli Co. can

meet different requirements of two synchronous gear box, double

output gear box

double synchronous planetary gear box, and the combination of

reducer and chain.

The combination of Sk-series double synchronous gear box is the

best configuration for double shaft paddle mixer.

3. High efficiency mixing unit

According to the properties of raw materials, the paddle can be

adjusted and designed accordingly

for example adding wear-proof plate, Teflon plate, and saw-toothed

paddle.

Double shaft paddle mixer can be also added high speed breaking bar

inside the barrel, scattering material following its flow.

4. Excellent discharging unit

Standard valve for double shaft paddle mixer is twin pneumatic

planar flap valves.

When close the valve, the planar flaps match the mixing barrel

perfectly, this makes no mixing dead zone and better mixing effect

5. Extra function

To realize the technicla of drying, cooling and keeping warm, the

mixer can be added a jacket structure out of the tank. Hot water or

steam or industrial oil can circulate int the jacket. Liquid

filling system can be installed at the top cover, the different

material of the atomized spray nozzle can realize the injecting of

acid or alkali liquid, or water.

The tank and the agitator can be coated with other material like

PE, PTFE, CARBIDE, etc. to realize the resistance of wear-out,

acid/alkali, or explosion etc.

Simple production mixing line as mortar mixer, cement mixer, putty

blender, paint powder mixer, etc.