Shanghai Shengli Machinery Manufacture Co., Ltd. |

|

LHY Stable Running Powder Production Line U Shape Container With Control Panel

In the “U” shape container, there are positive and negative ribbons, special proportion of

the two ribbons can be rectified with the kind of material, quantity and the proportion of

body. This mixer has good effect on mixing viscosity or cohesion powder.

Mixers machine used in big powder plants, powder production system, blender with feeding mahchine, control panel.

The production line including:

Feeding machine: manual feeding, crane big bag feeding, screw conveyor feeding, vacuum feeding, bucket elevator etc.

Mixing machine: doubel ribbon blender, single shaft mixer, mixing machine etc.

Filling machine: storage silo, screw conveyor, packing machine, big bag etc.

Double ribbon mixing equipment for cement blending, paint

blender, construction material blender

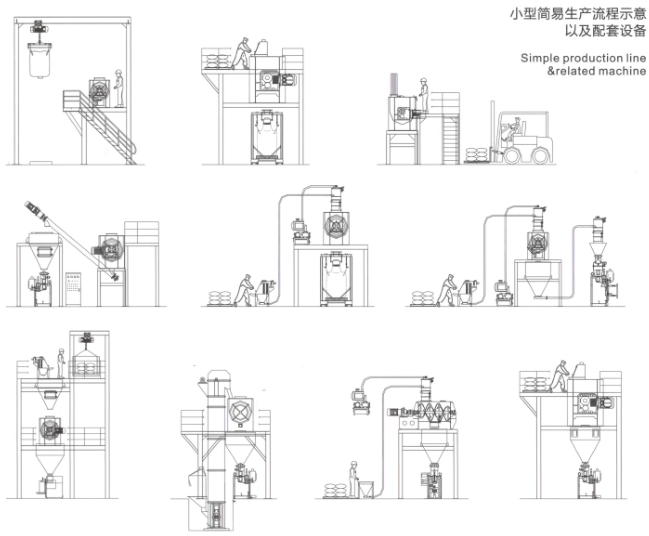

Simple system as dry ingredient bulk production mixing

line like:

C1: using crane to hang jumbo bag material and feeding the mixer

C2: mufti-level platform, manual undo the bag, mixing and packing

with a bulk bag packer.

C3: simple mixer frame, feed the mixer manually with the help of a

folk lift.

C 4: using manual feeding platform, after mixing, screw conveyor

send the material to the storage silo, a packer under it.

C5: load the material manually on the ground,use vacuum feed to

transfer material into mixer, after mixing, pack with a bulk-bag

packer.

C6: multi-stage vacuum feeder, store it after mixing, then packing.

C7: multi-level operation platform, elevator sending to material

silo, mixing, storage, and then packing. Tower structure.

C 8: bulket elevator feeding, mixing, storage, and packing.

C9: vacuum feeding, mixing, storage, packing.

C10:Manual feeding, mixing, storage, packing

Standard production line in construction or chemical material:

with two big raw material silos and weighing system:

1. two raw material like cement store in the big silo outside(if you have bulk material )

2. convey two raw material to the weighing silo by screw conveyor ( if you have bulk material)

3. the weighted material goes into the funnel of bucket elevator together with the other material like sand which is poured in by human will be transmitted to the mixer, little additives should be added through a small manual valve in the mixer!

4. all materials mix in the mixer for 5-10minutes

5. the mixture discharge into a silo

6. the worker starts to pack by packing machine, while another batch can go into mixer again

7. The output is 4-6 t/h