Hebei XinLianXin Water-Saving Group |

|

CNC PE electrofusion fittings wire laying Equipment

CX-20/160ZF Wire Laying Machine

CANEX PE Electrofusion fittings injection moulds

ELECTRO-FUSION WIRE LAYINGPE Electro Fusion pipe fitting mould -Tapping tee electrofusion mould - electrofusion moul

Size for : 20----160 Pipe couplings/45-90 elbow / Reducer/ Tee

Working way : vertical and herizontal

Electro fusion fittings made of : hdpe pipe /injection mould fittings.

Applications : E/F Coupling, Tee, Eelctrofusion 90degree Elbow,

45degree Elbow,

Flange, E/F Reducer, Electrofusion Pad,Saddle etc.

Non-standard wire laying machines can be customized.: new fixture/clamps/toolings necessary.

![]() CANEX INTERNATIONAL CORP., LTD is a comprehensive manufacturer for PE Electro Fusion

Fittings Equipment We develop Electrofusion wire

laying machines/Injection moulds /Wiring Terminal lathe. For

the production of electrofusion fittings used to join thermoplastic

pipes. We adopt Delta (Taiwan) CNC Controlled System/

CTB Servo Motor Schneider Electric /

OMRON etc. famous brand electrical appliances.

CANEX machines are strictly under the control of ISO9001:2000 QC

system. All CX-**/**ZF Series machines have high quality and stable performance. With

strong relationships and good credit,we cooperate closely to

develop the global markets together.

CANEX INTERNATIONAL CORP., LTD is a comprehensive manufacturer for PE Electro Fusion

Fittings Equipment We develop Electrofusion wire

laying machines/Injection moulds /Wiring Terminal lathe. For

the production of electrofusion fittings used to join thermoplastic

pipes. We adopt Delta (Taiwan) CNC Controlled System/

CTB Servo Motor Schneider Electric /

OMRON etc. famous brand electrical appliances.

CANEX machines are strictly under the control of ISO9001:2000 QC

system. All CX-**/**ZF Series machines have high quality and stable performance. With

strong relationships and good credit,we cooperate closely to

develop the global markets together.

Horizontal Wire Laying Model and Size Range

ONE---- Electrofusion fittings

Electrofusion fittings:

Electrofusion fittings are used as pipe connecting, tube inner wall surface embedded heating with copper wire,

copper wire at both ends of the connection dedicated electric welding machine with terminals.

Electrofusion Welding

Applying a controllable ends embedded in the copper tube fever upper power supply voltage terminal,

so that it is embedded in the tubular member under the action of the copper current to generate heat,

the surface of the plastic pipe and the inner surface of the pipe member is inserted into the tube and melt through the

plastic melt expansion force of the surface and the inner surface of the pipe fittings tangled molten plastic, play a role in the connection after melt cooling.

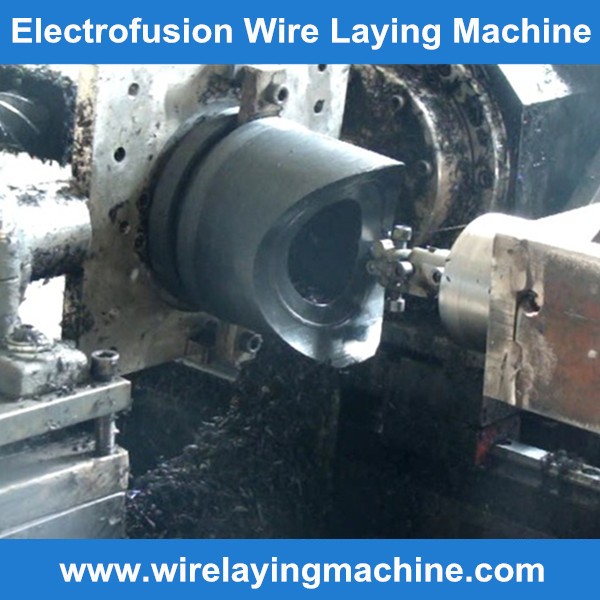

Electrofusion Wire Laying Machine-Process

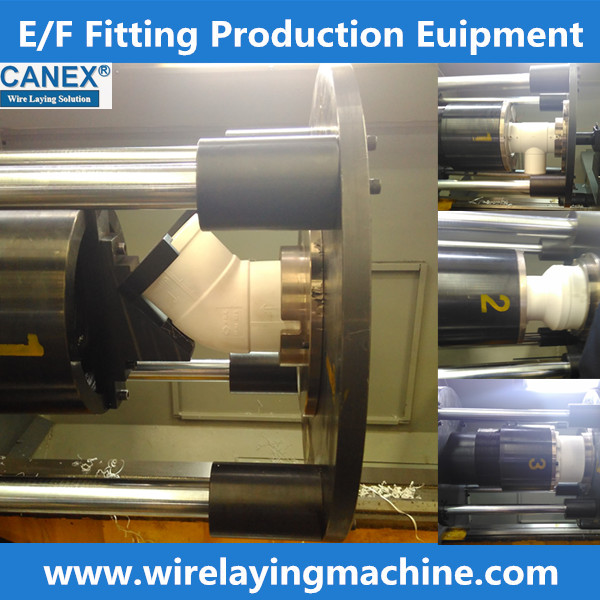

Injection Molded fittings or PE Pipe as material for Electrofusion fittings,By mechanical boring cutting to achieve required inner size,

Embedded copper wires into the fittings,shape the inner surface. All processes are finished after one time setup.

The principle of wire laying.

Pipe fittings rotate with special wiring tool.

The wiring cutter move in accordance with CNC Programming, form a continuous fixed or variable pitch;

Wiring tool cut the inner surface, scratched plastic will curve outside, embedded copper wire at the same time.

Close the scratched plastic with wheels.

Features

1 High precision of pipe inner size(Ovality less than 0.1mm).

2 Easy operation, Controlled by CNC Parameters.

3 Copper wire buried by the way of cold process.wires are not encounter relaxation force or fallen.

4 Low individual differences of resistance. Facilitate unified welding process.

Applications for wire laying machine

Pipe couplings :E/F Coupling,Tee, E/F 90°Elbow,45°Elbow,Flange,E/F Reducer,

Electrofusion saddle wire laying.

Production efficiency

Spec(mm) | 32-110 | 140-250 | 315-630 | 710-1000 |

Time(min) | 3-5 | 6-8 | 10-15 | 18-25 |

Tolerance(mm) | 0.05-0.1 | 0.05-0.2 | 0.1-0.2 | 0.1-0.2 |

Pitch(mm) | Any(CNC Programming Control) | |||

Pressure Ratings

The table as below provide a summary of the pressure ratings of the most common fittings.

PE100 -PN16 PE80 -PN12.5

SDR Ratings

The appropriate pipe SDR rating for electrofusion fittings is in accordance with the tables below:

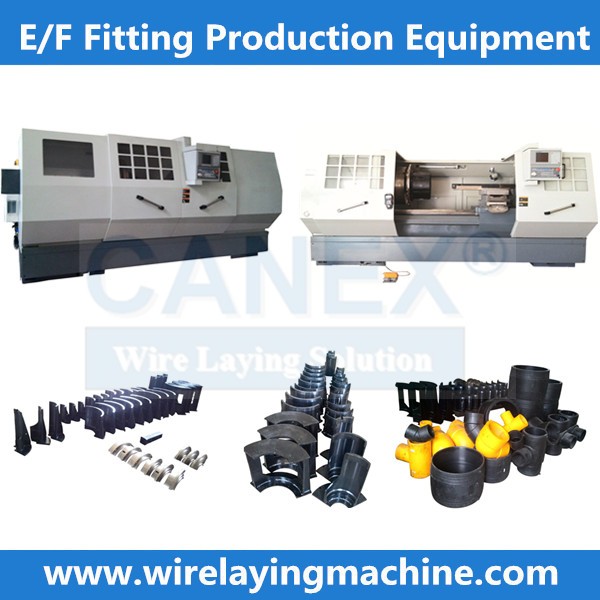

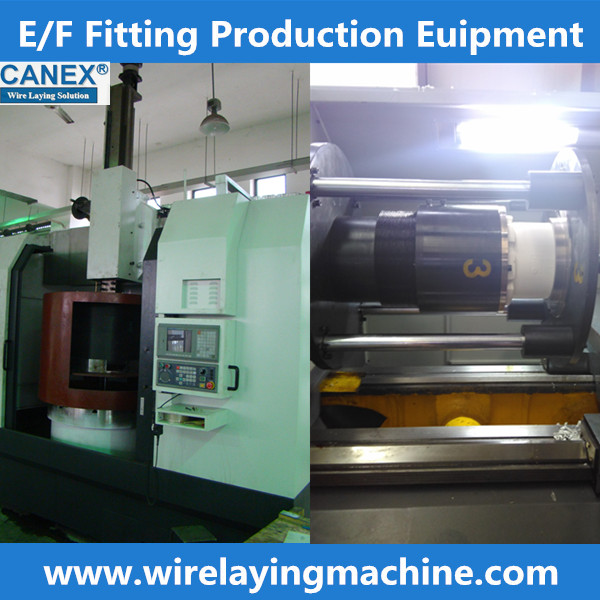

TWO---- Electrofusion fitting equipment

Device Configuration

1,Control system adopt DELTA CNC, our company united DELTA since 2009 , Develop 4 Axis CNC System according to our pipe fitting wire laying process design,

Our company own proprietary intellectual property rights.

2,Wire laying machine : Horizontal format machines and Vertical format machines.

3,Adopt hydraulic or pneumatic automatic way of fastening. 4 Axis CNC Control System assure production phase and repeatedly operations.

4,Adopt wireless hand wheel control, enjoy convenient operations

Equipment Operating Procedures

1 Pipes fittings put into machine main clamp manually.

2 Cutting inner surface of pipe fittings as per CNC Programming.Achieve required size

3 Embedding wires into pipe inner surface as per CNC Programming, meet design demands` pitch.(wire laying)

4 Shaping inner embedded wire wall as per programmed CNC,in order to reach targeted tech demands

Canex-Laying Wire Steps

1 Heavy boring.

Boring and chamfering under the condition of main axis started,

hole & angle as per tech demands,Edit program processing automatically. (can be changed as per demands)

2 Laying wire

The process of embedding wires called laying wire

3 Shaping.

Set final boring program comply with high demands on tolerance. (Exam.0.5mm distance from surface,set final boring program )

in order to assure roundness tolerance, inner hole tolerance,and assembling smoothly.

During the wire laying,the flipped plastic can not balance with inner surface,overmuch lead to inconvenient assembling,

suggest set final boring program. (as per practical situation)

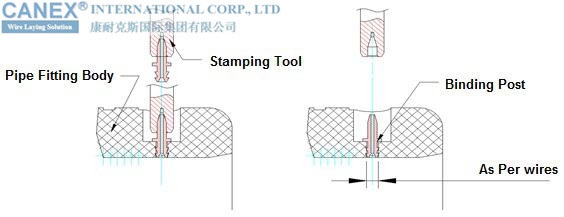

Binding Post

1 Cutting wire and pass through centre hole of Binding post ;

2 Put binding post into stamping tool;

3 Press binding post into pipe fittings, remain the end of resistance at middle taper hole of binding post

( or pass through whole binding post), make use of the taper different to mesh.

Connection----

1) New way of connecion : welding by IGBT Intevert welder+ Argon gas

2) Chart for electrofusion fittings binding post connection : buckle on widely used.

CNC Controlled electrofusion wire laying machine for pad wire laying vertical and herizontal

CANEX Electrofusion fitting mould /plastic injection moulds developing.

CANEX CX-32/160ZF electrofusion wire laying machine

Fullsealed Electrofusion Wire Laying Machine

Long bed - horizental wire laying machine

canex electrofusion wire laying machine

Special Toolings/Fixture/Clamps for electrofusion coupler, electrofusion elbow, electrofusion tapping tee, end cap

canex wire laying ma

CANEX PE Electrofusion Saddle wire laying equipment

Electrofusion tapping tee wire laing machine

Electrofusion pad wire laying machine

CNC Vertical Wire Laying Machinefor medium and large electrofusion fittings -

canex wire laying machine

E/F fittings practical working.

canex wire laying machine

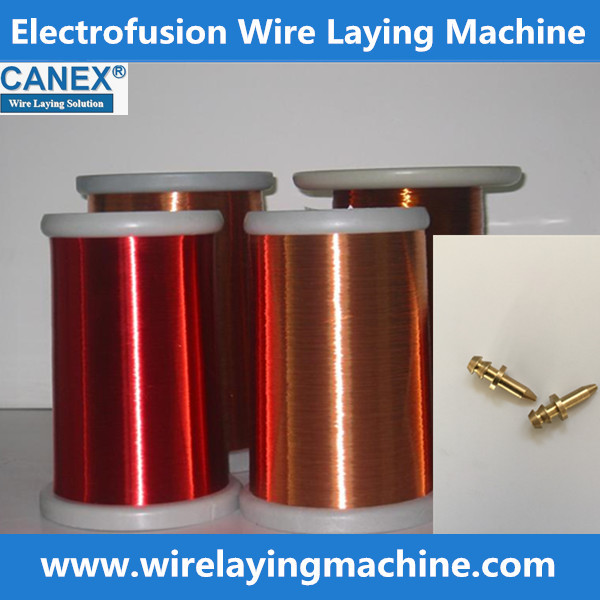

Terminal Pin ( Binding Post )/ Electrofusion wires canex wire laying solution