Share Group Limited |

|

Verified Suppliers

|

|

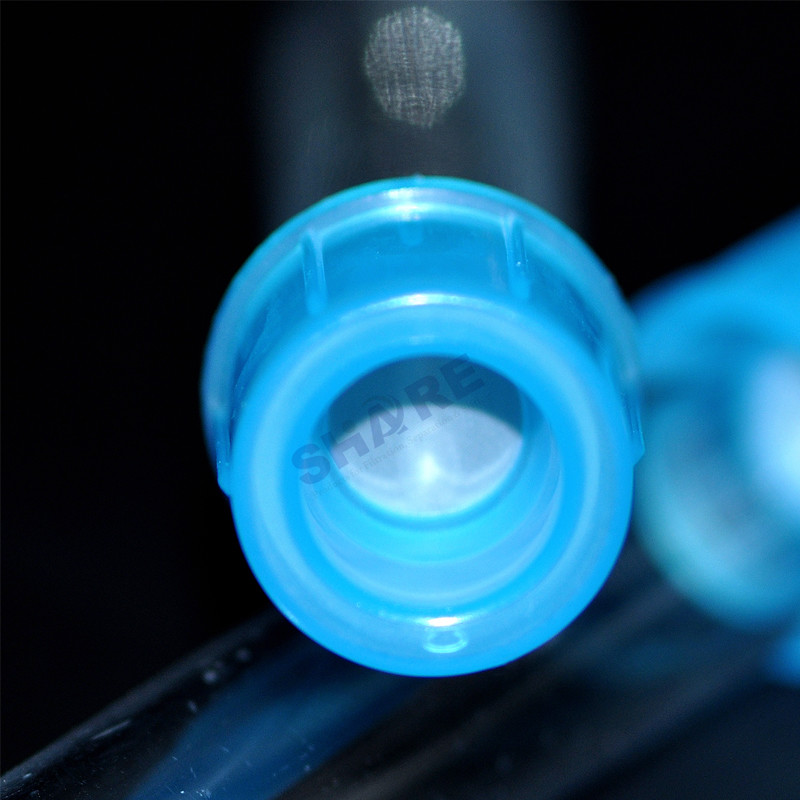

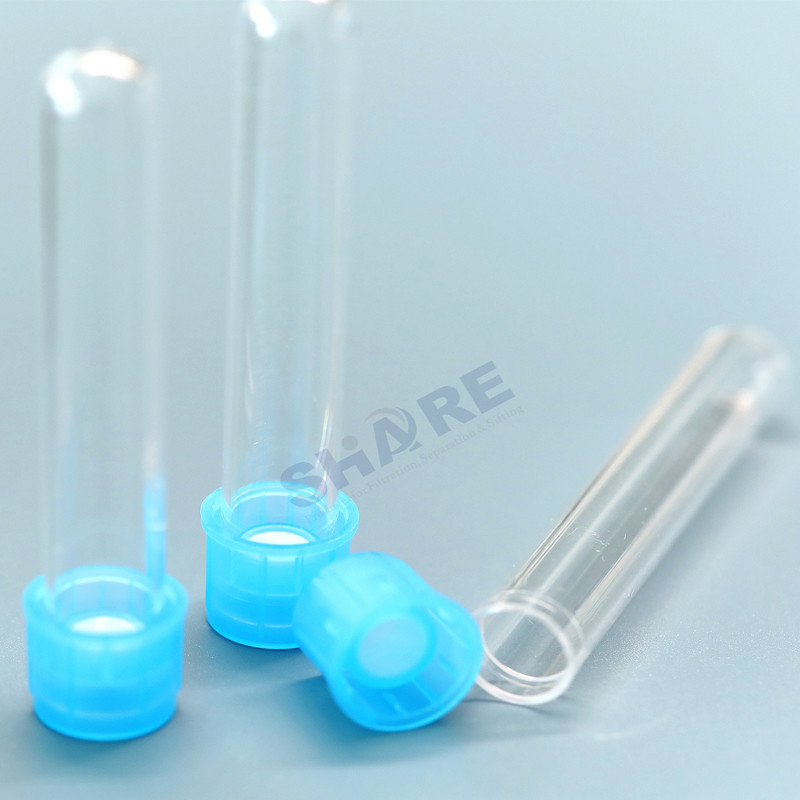

SHARE cell strainer cap for stem cell and tissue derived primary cell preparation

--- A simple solution for producing uniform single-cell suspensions

--- Designed to fit perfectly into round bottom centrifuge tube

--- A faster and easier alternative to gauze filtration in

procedures involving dissociation of cells from either clumps or

primary tissues

--- Many different pore sizes are available: 20um 35um 40um 70um

100um

--- Color coded by mesh pore size.

SHARE cell strainer caps are made of molded plastic with nylon mesh

filter. Our cell strainers are perfect for obtaining uniform single

cell suspension from various sources. Cell strainers are made from

nylon with many different pore size meshes, generally 20um 35um

40um 70um 100um, showing optimal performances in a variety of

applications such as stem cell and primary cell preparation.

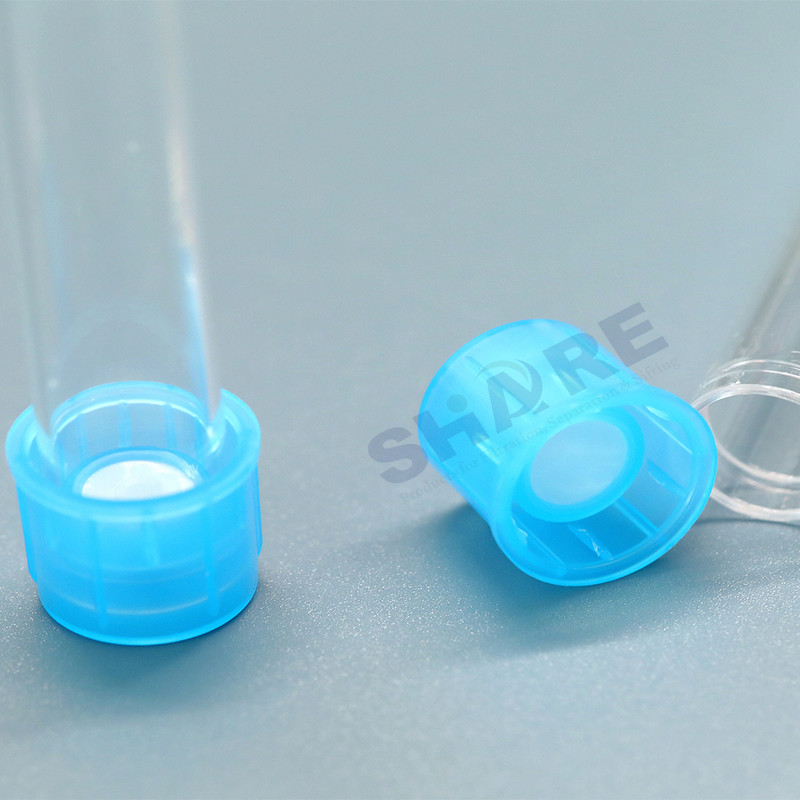

SHARE offers molded plastic cell strainer snap cap for a wide range

of laboratory applications where the filtration and the

purification of liquids is required. Its unique design features

improved ventilation to avoid clogging for a smart sample

preparation. Our cell strainer are stackable to allow direct

filtration with different mesh sizes and alsocan be inverted to

recover the sieved material. For large sample volumes it can be

combined with a funnel.

Many different pore sizes are available: 20um 35um 40um 70um 100um,

color coded by mesh pore size.

It fits for 15 ml conical centrifuge tubes, blood collecting tube,

flow cytometry tube, 3 ml tube, 2 ml cryo tube, 5 ml conical tube

screw cap, 5 ml reaction tube snap cap, 2 ml reaction tube, 1.5

reaction tube, 48 well plate, 24 well plate.

Specifications

| Product Name | 20um Nylon Mesh Strainer Cap for Flow Cytometry Tubes |

| Manufacturer | Taizhou Share Filters Co. Ltd. |

| Brand | SHARE FILTERS |

| Material | Polypropylene frame with nylon mesh filter |

| Pore Size | Generally 20um 35um 40um 70um 100um |

| Color | White, yellow, blue, red or customized, color coded by mesh pore size |

| Size | 1cm or customised |

| Fit for | Most brands of test tubes: 15 ml conical centrifuge tubes, blood collecting tube, flow cytometry tube, 3 ml tube, 2 ml cryo tube, 5 ml conical tube screw cap, 5 ml reaction tube snap cap, 2 ml reaction tube, 1.5 reaction tube, 48 well plate, 24 well plate |

| Usage | Cell culture in laboratory, flow cytometer cell sample, impurity filtration, cell dispersion, sampling, etc |

| Package | Individual single packaged, 100pcs/carton |

Gallery

SHARE has the ability to engineer woven mesh fabrics into finished or partly finished products by insert molding or over molding. With its industrial lines and long-standing experience, we provide fabrics cut to size, lot-to-lot consistency and high quality custom fabricated components, in almost any requested shapes.

Filter Mesh Selection

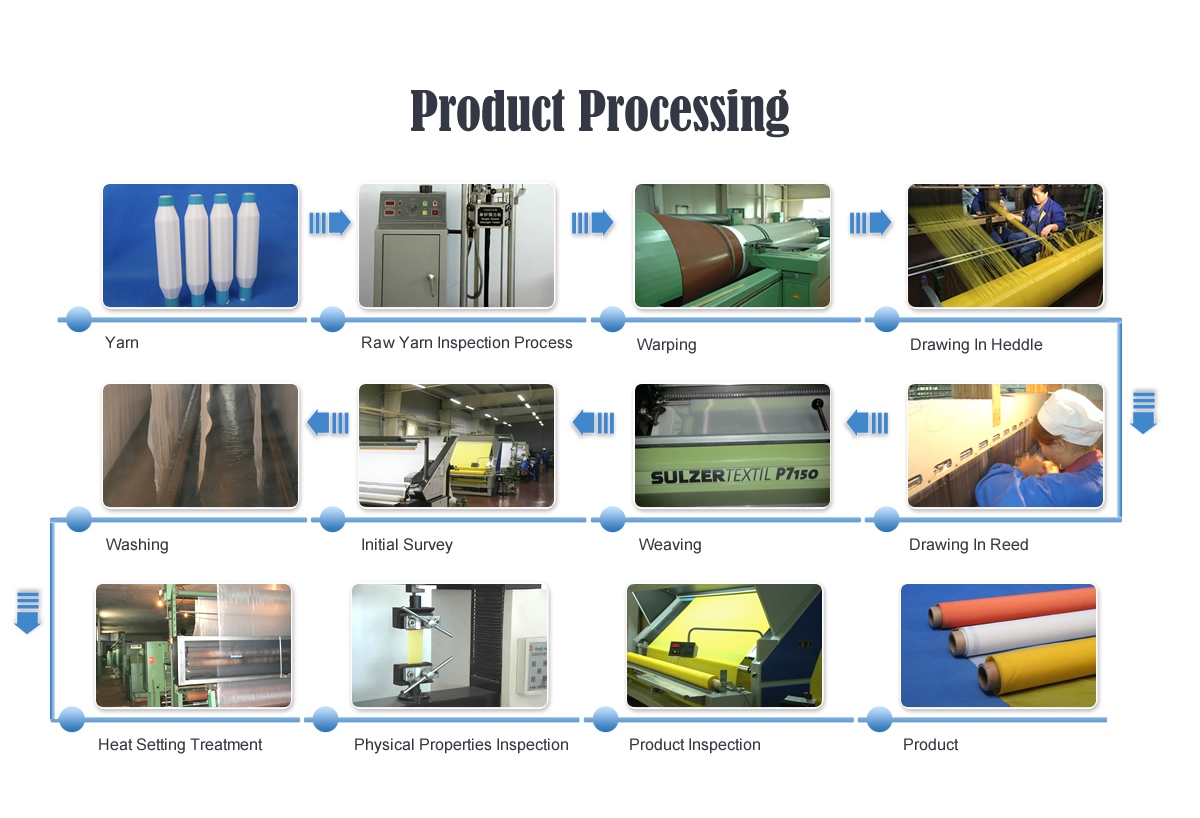

The productions of SHARE's nylon filter meshes include at least twelve steps, ensuring high quality products.

Yarn→Raw yarn inspection→Warping arranging→Drawing in

heddle→Drawing in reed→Weaving→Initial survey→Washing→Heat setting

treatment→Physical properties inspection→Products

inspection→Product→Fabrated filter and screens if needed→Molded

plastic filters if needed Plastic Selection

Plastic Selection

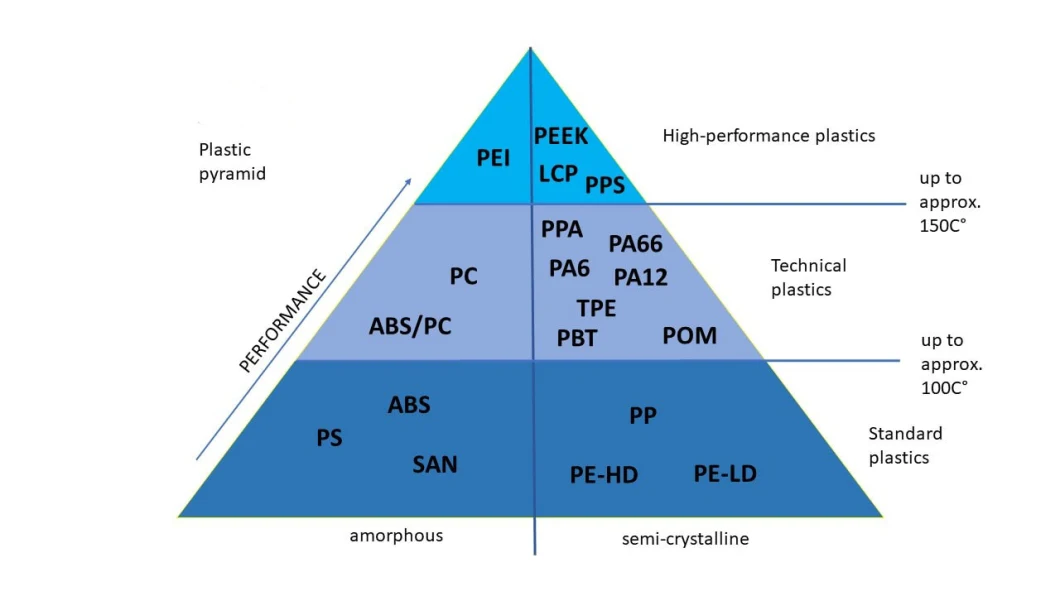

Material property is an important know-how to injection molding. It is highly related with molding quality, finish and cost. Our team devote this knowledge and experience to the molding products of our customers. From various thermoplastic (PA, PP, PC, POM, PET, ABS and Peek) to thermosetting (PE, Epoxy and Silicon) even combined plastic materials (such as glass fiber), we put material property as a must-evaluation when design tooling, so we would also help to suggest equivalent materials for quality improvement or cost reduction.

| Artificial or Synthetic Fiber Chemical Resistance Comparison | ||||||||

| Fiber Type | Continuous Working Temp. | Max. Working Temp. | Filtration Characteristic | Abrasion Resistance | Hydrolysis Resistance | Acid Resistance | Alkalis Resistance | Oxidation Resistance |

| PVC | 75ºC | 80ºC | Good | Excellent | Excellent | Excellent | Excellent | Good |

| PP | 90ºC | 100ºC | Good | Good | Excellent | Excellent | Excellent | Poor |

| PA | 110ºC | 115ºC | Moderate | Excellent | Poor | Moderate | Good | Moderate |

| PAN Copolymer | 120ºC` | 130ºC | Good | Good | Good | Moderate | Moderate | Good |

| PET | 135ºC | 150ºC | Excellent | Excellent | Poor | Moderate | Poor | Good |

| m-Aramide | 180ºC | 220ºC | Excellent | Excellent | Moderate | Moderate | Moderate | Good |

| PPS | 190ºC | 200ºC | Excellent | Good | Excellent | Excellent | Excellent | Moderate |

| Polyimide | 240ºC | 280ºC | Excellent | Moderate | Good | Good | Moderate | Excellent |

| Polyertrafluoroethylene | 250ºC | 280ºC | Moderate | Good | Excellent | Excellent | Excellent | Excellent |

| Fiberglass | 250ºC | 280ºC | Moderate | Moderate | Excellent | Poor | Moderate | Excellent |

FAQ

FAQ

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your

evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly

notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production once you have

placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process.

Additionally, we have spot inspections and final inspections

carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting

capabilities from yarn over weaving to converted items with

professional technical team and quality guarantee and management

for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.