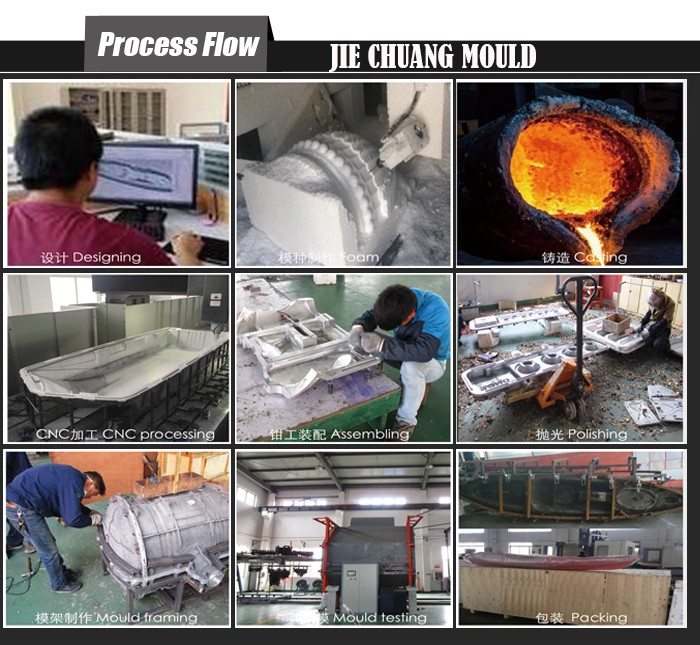

Shanghai Jiechuang Mold Manufacturing Co., Ltd. |

|

| ||||||||||||||||

| ||||||||||||||||

|

|

J&C ROTOMOLD manufacturer, customized different styles and sizes tool cases, military boxes, kits for you.

RFQ

A: We are factory.

A: Generally it is 35 days after confirming drawing and receive advanced payment.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

A: 50% advanced payment, the balance before shippment.