LIANDA Machinery Co.,Ltd. |

Pre-crystallization and dryer for PET chips/scraps/pellets for PET mono filament extruding machine

Heating.Heating granules and regrind material prior to further processing (e.g. PVC, PE, PP,…) inter alia to improve the throughput in the extrusion.

Crystallization.Crystallisation of PET (Bottleflakes, granules, flakes), PET masterbatch, co-PET, PBT, PEEK, PLA, PPS, etc.

Drying.Drying of plastic granules, and –ground material (e.g. PET, PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU) as well as other free-flowing bulk materials.

Coating.Coating of adhesives (e.g. Hot melt, EVA+lime,…)

High input moisture.Drying processes with high input moisture >1%.

Diverse.Thermal processes for the removal of rest oligomeren and volatile components.

Our processing

Normally the PET Bottle flakes or sheet scrap with initial moisture level of up to 10000-13000ppm. The PET Bottle flakes or sheet scrap (Virgin or mixed ) will be recrystallized in Infrared crystal dryer in 20mins, the drying temperature will be 150-180℃ and dried to 50-70ppm,then fed to Single screw extruding system for further processing

l Limiting the hydrolytic degradation of the viscosity.

l Prevent increasing AA levels for materials with food contact

l Increasing the capacity of the production line up to 50%

l Improvement and make the product quality stable-- Equal and repeatable input moisture content of the material

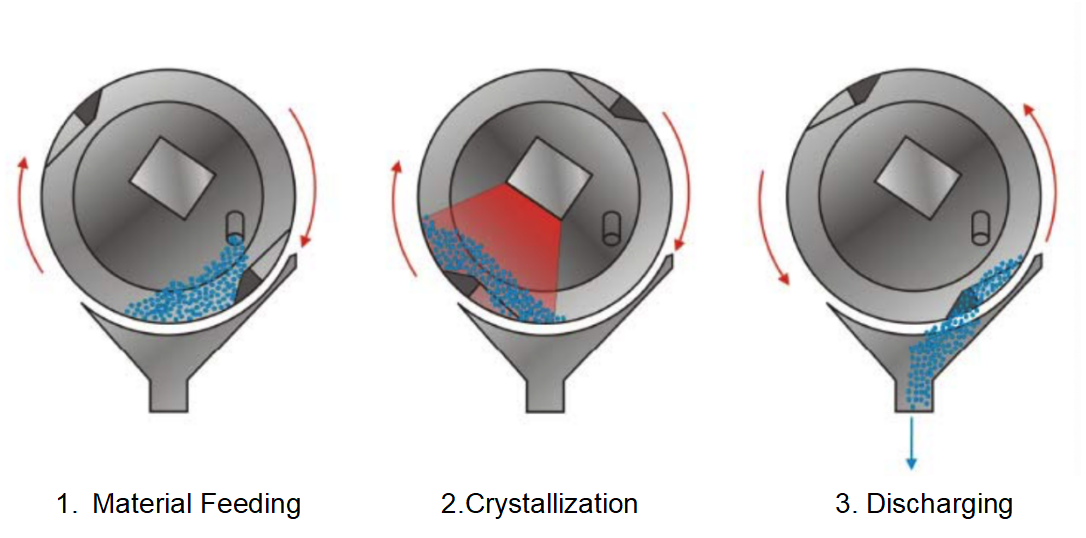

1. Material Filling

By vacuum dosing feeder to convey the raw material continuously to the rotating drum

2. Drying and Crystallization

Thermal treatment and mixing. There are the spirals welded into the rotary drum to ensure the well mixture of material and continuous transfer to the outlet. And the material will also be dried continuously

3. Discharging

The dried and crystallized material will be discharged after minutes drying by drum rotary. Finally the dried and crystallized material will be conveyed to the next processing.

| No | Infrared crystal dryer | Conventional dehumidifier and crystallizer |

Comparison: Take 500kg/h Infrared crystal dryer and 500kg/h Conventional dehumidifier and crystallizer as example | ||

| 1 | Processing | |

| Dry and crystallizer at one step processing | Dehumidifying and Crystallizer separated | |

| 2 | Drying time | |

| 20mins | Dehumidifying 4-5hours Crystallizer 40-60mins | |

| 3 | Energy cost | |

Installation power: 42kw Practical energy cost: 20KW/H | Installation power: 156kw Practical energy cost: 78KW/H | |

| Infrared crystal dryer Energy savings up to 45% | ||

| 4 | Space saving | |

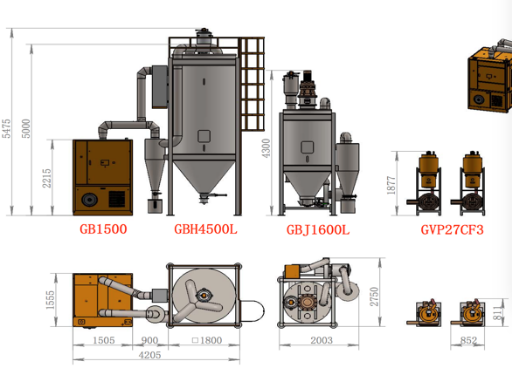

|  | |

| Infrared crystal dryer is up to 300% space saving | ||

| 5 | Maintenance | |

| Infrared lamp working life 7000-10000hours. If broken, just pull it out and insert new lamp. And all lamps are controlled by PLC system, no need to adjust the heating temperature | Molecular sieve have to be examed at regular time. If blocked, you have to changed all Molecular sieve and adjust the dew point and test the dryer again | |

|  | |

| Infrared crystal dryer is much easier for start, operate and maintenance | ||

HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped

with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by

inspecting personnel.

● Each assembly is in charged by a master who has working

experience for more than 20 years

●After all the equipment are completed, we will connect all the

machines and run the full production line to ensure the stable

running in customers' factory

Our Service![]()

1.We will provide testing if the customer comes to visit factory to

see the machine.

2.We will provide detail machine technical specification ,electric

diagram,installation,operation manual and all the documents which

customer needed for clearing customs and using the machine.

3.We will provide engineers for helping installation and training

the workers at customer's site.

4.Spare parts are available when they are needed .Within warranty

time,we we will provide spare parts free,and over warranty time,we

will provide spare parts with factory price.

5.We will provide technical support and repair service in the whole

lifetime .