Dongguan Howe Precision Mold Co., Ltd. |

|

Verified Suppliers

|

|

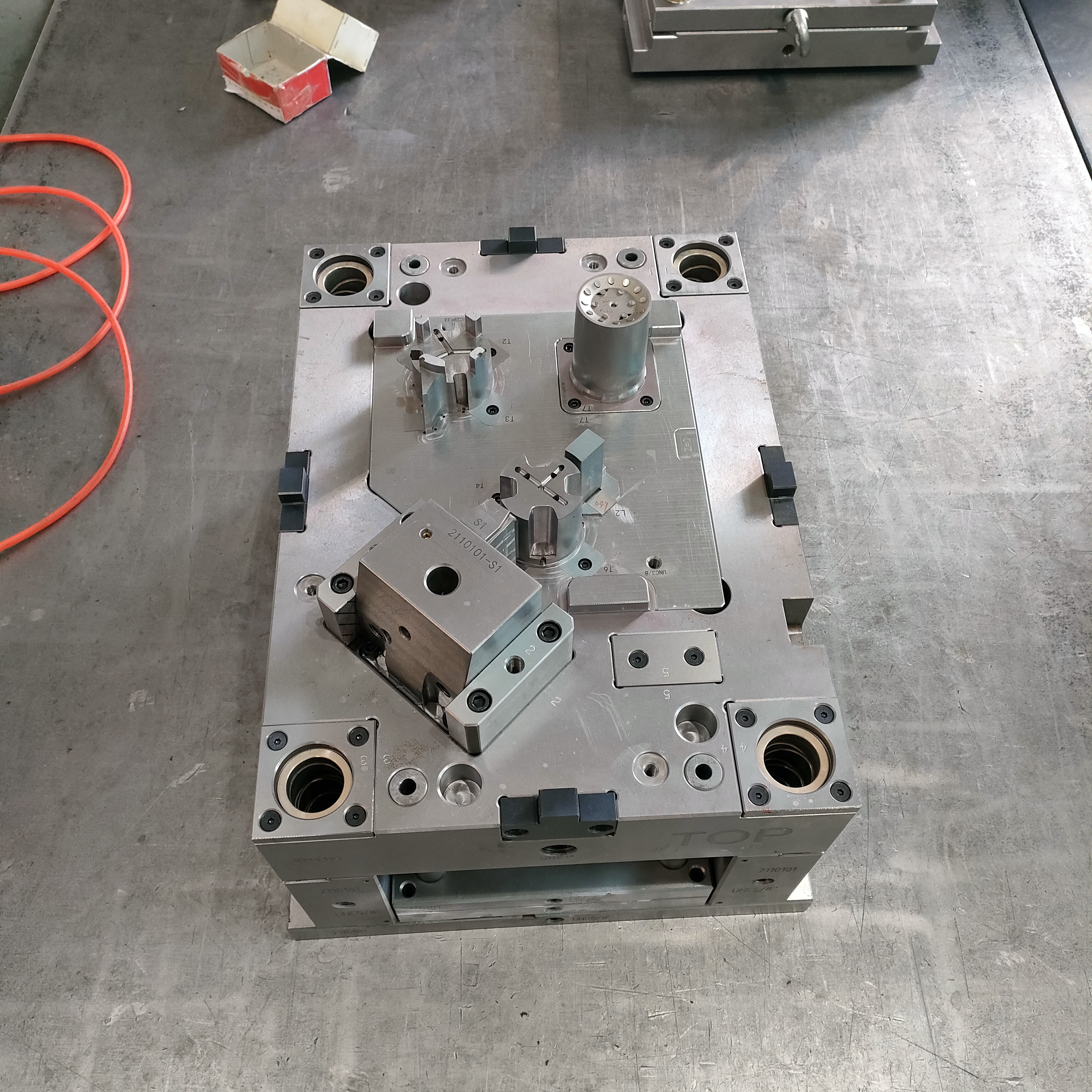

500000 shots life time Custom Plastic Injection Mold with Texture

mold surface finish

Mould Information:

| Material of steel | cavity and core use imported S136 stainless steel with fine polishing, high hardness to get mold's high precision and good quality. |

| About gate | pin-valve gate, pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actions on each cavity. reliable seal function, smooth moving, low thermal expansion rate, long using life and also saves electric energy. |

| About hot runner | hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production, cavity with lower injection pressure to reduce wear and tear of mold parts. |

| Heat system | with a double heating system, it has separate temperature control mode, the heat bar is used to heat the mold manifold plate, small heaters supply the heating temperature for cavity nozzle continuously. |

| Cooling system | each part including core, cavity and valve gate has an independent cooling system. |

| Metal Material | Aluminium, Steel, Stainless steel, Copper, Magnesium, Cast iron, Zamak, etc |

| Plastic Material | ABS,PC,POM,PMMA,NYION,ABS+PC,PBT,PBT+GF30,PPS,PPS+30GF,PA6+GF30,PEEK,PEI,Bakelite. |

| Color | Customized (painting or anodizing) |

| Process | CNC Turning, Drilling, Milling, Punching..... |

| Tolerance | +/- 0.01~+/-0.05 |

| Surface Treatment | Smooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,Brushing |

| Application:Automotive industry / Aerospace/ Telecom equipment/Medical / Marine / Construction / Lighting system/Industrial Equipment & Components, etc. | |

| Packaging | Wood case or carton box 1. With plastic bag, with pearl-cotton package 2. To be packed in cartons or wood case 3. Use glass tape to seal cartons, or pin tight the wood case with nails. 4. Deliver out by DHL, FEDEX Or according to the customer‘s requirement. |

Why choose us?

Howe provide one-stop service for high volume and technical Plastic

Injection Moulding - from product concept design, injection

moulding, tooling, plastics manufacture, assembly and packaging on

an international basis - we can help you concentrate on your

business.

The important thing we can offer you a very competitive price and

provide the advanced solution with your porducts design to reduce

the mold and producing costs to help your products to be

successful.

If you are after a bespoke solution to your high volume plastic

injection moulding product requirements then Howe could be the

partner for you. If you are in the Medical, Construction,

Aerospace, Defence, Nuclear, Automotive, Security, Agriculture or

Personal Care industries, then Howe could help.If you are a forward

thinking company that wants assistance through every step of the

product concept process, then on to the custom plastic injection

moulding, we could offer you a solution.

Workshop

Q1: What kind of molds do you make? Plastic injection mold,

Compression mold or something else?

A1: We are mainly making plastic injection mold and die-casting

mold.

Sometimes we also make rubber molds according to our customer’s

requirements.

Q2: Do you build hot runner plastic moulds?

A2: Yes. We build hot runner Plastic Moulds and specialized in many

different systems, such as DME, Master, Mastip, Hasco, Yudo, Incoe,

Husky, etc.

The manifold recommended for your tool is selected to meet your

individual needs.

Q3: What types of files do you accept (drawings)?

A3: With our CAD systems we can accept the following files:STP,

IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc.

Q4: What kind of steel do you use for plastic mouldings?

A4: We can use any type of steel appointed by customer or popular

in the market.

Such as P20, 718, 8407, NAK80, H13, S136, DIN 1.2738, DIN 1.2344,

etc.

Q5: Can you provide the steel certificate and heat-treatment

certificate?

A5: Yes, We can provide steel certificate or hardness certificate

to prove.

Q6: Can you make the texture/text/heat-treatment/nitriding for the

injection mold plastic?

A6: Yes, As a plastic mold factory, we have long-term cooperated

subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q7: How long is the lead-time for a plastic injection mold?

A7: It all depends on the mold’s size and complexity. Normally, the

lead time is 25—45days.

If the Plastic Mouldings are very simple and not big size, we can

work out within 15 days.

Q8: Do you make spare parts for your customer?

A8: Yes, we will provide spare parts for the mold if needed or

required by clients.

Q9: How do you pack the plastic moulds?

A9: We pack the plastic moulds with a wooden box.

There are the main 3 operation steps.

First Step: We daub some rust preventive oil on the mold.

Second step: We pack the mold with thin plastic film to avoid

moisture.

Third step: We put this plastic film packed mold in a wooden box,

and fix it to avoid any movement.