Dongguan Howe Precision Mold Co., Ltd. |

|

Verified Suppliers

|

|

Car Center Control Panel B Pillar Plastic Interior Trim Hasco Injection Mould

Howe Mold is professional in the plastic injection mold. The injection mouldings parts include automotive parts & motorcycle accessories (dashboards, inner decorating accessories, fender, bumper, etc. ), household appliance products (microwave oven, juicer, etc. ), electrical appliances (washing machine, air conditioner, refrigerator, television, etc. ), IT industry products (cell phones, computer, etc. ), office accessories (telephone, printer, etc. ) as well as other varieties of products. We look forward to participating in the success of your next project.

Mould Information:

| Product Material | ABS,PP,PC,PA,PMMA,PS,POM and etc. |

| Moldbase | FUTABA,LKM,HASCO,DME you can choose |

| Cavity material | 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc |

| Runner | Cold/Hot runner |

| Cavity | Multi or single cavity |

| Gate type | Side gate,Sub gate,Pin point gate,Edge gate etc |

| Treatment | Heat treatment and Nitriding,polish etc.. |

| HRC | H45~52 |

| Product weight | 50~5000 K |

| Machine type | 130ton-550ton |

| The way of Color contrast | RAL K7,PANTONE |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, the weight of the product, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold | Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 pieces), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your requirements. |

| 8. Delivery | deliver goods by air or by sea. |

Company profile

Quality Control

Why Choose Us?

1. Manufacturing and exporting experience for over 10 years.

ISO 9001 approved.

2. Products are supplied to over 50 countries.

3. One-stop service for plastic injection mould and plastic

parts. Save time and save money for you.

4. In-house mold design and building capabilities.

5. No reclaimed material used to ensure high quality.

6. Keep secret to your idea and your design.

7. 24 hours (two shifts) / 6 days for production.

8. Professional design team, mold maker engineer. OEM/ODM service.

9. Professional QC and R&D teams to assure high quality.

10. Professional sales team.

11. No MOQ.

12. Prompt delivery. For prototype: 3-7 days. Production orders can

be arranged specially to meet customer's urgent demands.

13. Geographical advantages: within 30 minutes to airport or sea

port, near to Hongkong.

Our Services

Our workshop

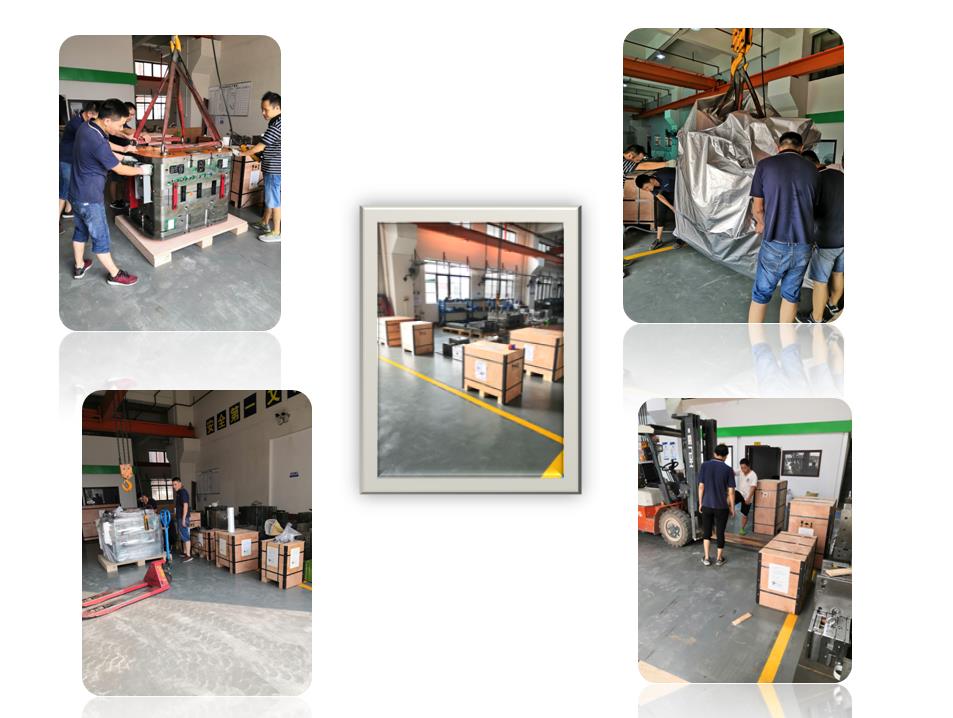

Packaging detail

FAQ:

1. Q: Which kind of product can you do?

A: Plastic injection molding and mass production for plastic parts.

2. Q: What kind of information needs for a quotation?

A: 1) Sample photo with size or 2D/3D design

2) Product material

3) The quantity

4) Runner type, cold or hot

5) Mould steel type, P20, 718, 2738, H13, S136, 2316, and so on.

3. Q: I have no 3D drawing, how should I start the new project?

A: You can supply us a sample or tell me your idea, we will help to

finish the 3D drawing design.

4. Q: How long will be the injection mold finished?

A: Usually it will take about one month to finish the mold.

5. Q: How about the samples?

A: After mold finished, We will make some samples for you to check

as soon as we finish the mold and then deliver the samples for you

to check.

6. Q: How about the mould modify?

A: You can tell us your comment about the samples after you receive

them. If there is any dimension different from the drawing,

we will modify the mold for free on our side and then make the new

samples.

7. Q: How about the proprietary rights of the plastic injection

mold?

A: Customer paid the mould so it all belong to Customer.

8. Q: How about the surface treatment?

A: Metallization (chrome, gold, silver) / Painting (hand, screen,

automated) /Vacuum plating / Lithography / Custom texturing/

Hydrographics.