SUZHOU FOBERRIA INDUSTRY AND TRADING CO.,LTD |

|

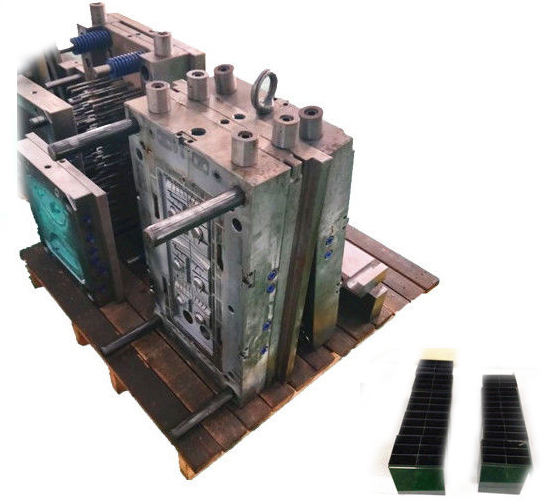

Welcome to SUZHOU FOBERRIA Customized lead acid battery plastic case injection mould / mold

Company Profile

FBR mould is known as one of the professional manufacturers and

exporters for plastic vent plug and plastic injection molding tools

for battery box / container mould,car battery mould,auto parts

mould,power tool injection mould,medical mould ,home appliance

mould plastic bucket /bowel mould and so on. OEM is available.We

have rich export experience and strict quality control .

We guarantee good quality and competitive price. FBR mould always

keep in touch with customer in every step to ensure that all the

details are in accordance with customer request.

What ‘s the Order process?

Step1:R&D

We support your R&D and make product design drawing as per

original sample or improve the mould drawing design if you want.

Step2: Negotiation

Make negotiation about the quality,price,material,delivery time and

payment,etc.

Step3: Place an order

You can place an order according your own design or choose by our

design.

Step4: Mould production

We will send mould design for customer approval first before the

mould production and then send samples to customer when finish the

process according to customer request.

Step5: Sample confirmation

Send mould test video and photos by email first and then send out

the samples by express for customer final confirmation.

Step6: Delivery

Pack moulds with wooden cases by sea or by air according to

customer’s requirement.

Quick Details

1. Cavities: single or as per your requirements cavity

2. Treatment: S45C Pretreat>25Hrc,And Nitriding

3. Hot runner: according to your demand

3. Life time: >300 Thousand Times

4. Package: Plywood case, anti-rust paint

5. Transport: By Sea or Air

6. Main process: Milling,grinding,CNC,EDM,wire-electrode cutting,

carved,electrospark,lathe,surface treatment

Best material for my design

Materials selection depends on the application of your design and

the environment in which it will function.But we can discuss the

alternatives and suggest the best material for you.

Our Features

1. Precision parts strictly according to customer&request drawing,packing and quality request

2. The most advanced inspector to ensure the quality

3 .Experienced technology engineers and well trained workers

4. Fast and timely delivery. Speedily&professional service

5. Quality assurance in accordance with ISO9001:2008