Zhangjiagang Beisu Machinery Co., Ltd. |

|

Verified Suppliers

|

GF180 Twin screw extruder hard PVC profile production line for electric trunking

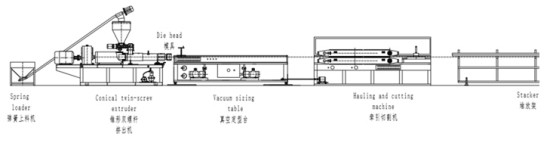

Layout:

PVC Raw material+additive→Mixing Unit→Auto Feeder→Conical Twin-screw Extruder→-Moulds→Vacuum Calibration Tank→Haul-off&Cutting Machine→Stacker

Features specifications:

PVC trunking, that is, PVC trunking (PVC = Polyvinylchlorid, polyvinyl chloride, a synthetic material), generally known as line trunking, wiring harness, wire trough, etc. PVC trunking is a kind of trunking. There are various types of trunking. Depending on the material, the trunking is divided into various types according to the wiring equipment industry. The commonly used environmentally friendly flame-retardant PVC trunking and halogen-free PPO Wire troughs, halogen-free PC/ABS trunking, metal wire troughs such as steel and aluminum, etc.

Details specification pictures of PVC ceiling panel production line:

Main technical parameter:

| Model | SJSZ45/90 | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 | SJSZ80/156 |

| Screw Diameter(mm) | 45/90 | 51/105 | 55/110 | 65/132 | 80/156 |

| Screw Speed(rpm) | 1-45.5 | 1-30 | 1-38 | 1-30 | 1-36.9 |

| Motor Power(kw) | 15/11.5 | 22/18 | 22/18 | 37/24 | 55/36 |

| Output(kg/h) | 40-70 | 60-100 | 70-150 | 80-250 | 250-400 |

| Net weight(kg) | 3000 | 3500 | 3800 | 4000 | 5000 |

| Max Width(mm) | 180 | 240 | 400 | 600 | 800 |

| Drawing Height(mm) | 140 | 140 | 140 | 140 | 140 |

| Drawing Force(fn) | 15 | 30 | 30 | 40 | 50 |

| Drawing Speed(m/s) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Auxiliaries Total Power(kw) | 18.7 | 31.6 | 31.6 | 31.6 | 31.6 |

| Outline Dimension(mm) | 3360*1290*2127 | 3620*1050*2157 | 3620*3500*2157 | 4235*1520*2450 | 4750*1550*2460 |

Use and maintenance:

Plastic profile extrusion die is the core part of extrusion

production. The technical state of plastic profile extrusion die is

directly related to the stability of extrusion production, the

quality of extrusion products, the efficiency of extrusion

production and the service life of the die itself. Therefore, the

correct use and maintenance of plastic profile extrusion dies is

very important.

1. Unpacking inspection of plastic profile extrusion die after

arrival

Unpacking inspection, the packaging is intact: After unpacking,

take out the packing list, the instruction manual and other

technical documents, and build the parts, accessories and special

tools according to the contents of the packing list.

2. Half technical requirements and status of plastic profile

extrusion dies

>> Plastic profile extrusion die, especially when the

extruded material is modified polyvinyl chloride, the molded parts

are generally made of corrosion-resistant materials such as

stainless steel, and tempered to HRC24 or above to ensure a certain

service life.

>> The working surface of the die, the shaping die and its

parts should be smooth, and there should be no defects such as

bumps, scratches, burrs, attachments and rust.

>> The die runner system should be gentle along the direction

of the melt flow, avoiding sudden changes in the cross section and

the stagnant zone.

>> There should be reliable positioning between the

templates. The repetitive error of the corresponding position

between the templates is not more than 0.03mm. The joint surfaces

of the plastic extrusion die and the splicing splicing should be in

close contact with each other. Must not be greater than 0.02mm.

>> The cooling system and vacuum system of the fixed mold

should be smooth and not leaking. Under normal circumstances, the

water and gas systems should not collude with each other. The water

pipe joint of the plastic profile extrusion die sizing die, the

vacuum pipe joint shall have obvious signs and shall not affect the

connection of the pipeline.

>> Plastic profile extrusion die setting die should be

flexible and flexible, and the sections in the fixed die and water

tank should ensure a certain degree of coaxiality.