Xiamen KaiYuanSheng Industrial Co.,Ltd. |

|

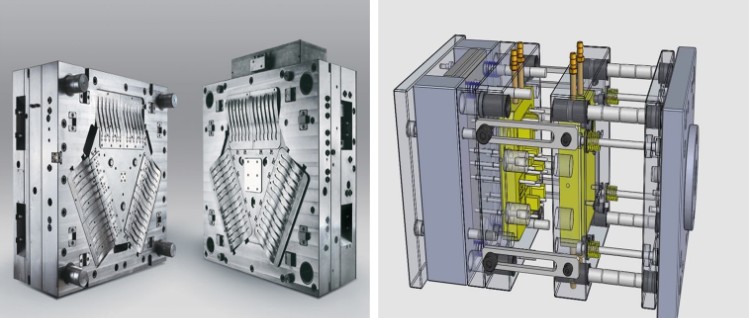

ODM/OEM Customized Plastic Injection Mould Tool For Plastic Parts

Plastic injection Molds and Mass Production Manufacturer

1- Start from part design analysis

2- Mold design drawing and DFM report available so you can see how

is the mold going to be before mold making

3- If product is complex,moldflow report will be present as well

4- In house mold making shop ensure you mold quality under well

control.

5- Normally it takes 20-40 days to make mold,precise time depends

on part design

Our advatage as following:

Quality first,Best service,12 years much experience,wide export

Pretty competitive price,we offer good services and excellent

communications.

We have rich experience in export to European,USA,and other

countrie.

Delivery time is very on time,can catch your delivery time as your requirements well.

Basic information:

| Mold Base | LKM, HASCO, DME or your requirement |

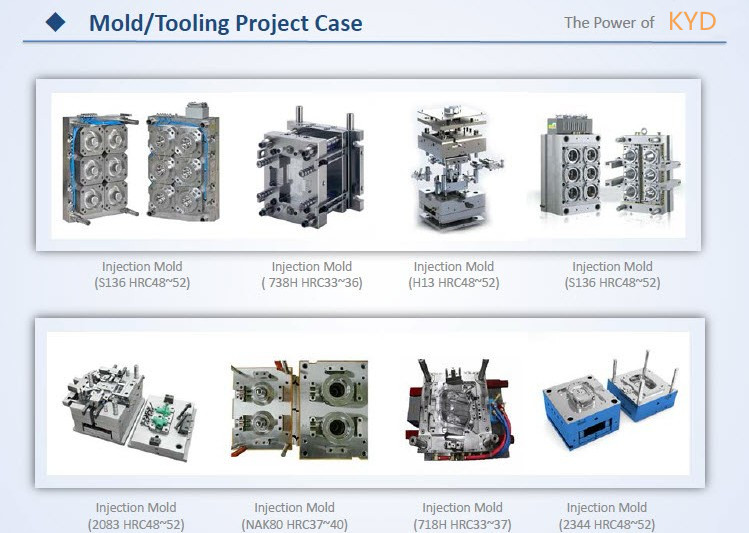

| Mold Material | 45#, P20, H13, 718, 1.2344, 1.2738 and so on |

| Standard | HASCO, DME, MISUMI, PUNCH and so on |

| Product Material | PC/ABS, ABS, PC, PVC, PA66, POM or other you want |

| Runner | Cold/Hot Runner |

| Gate Type | Side gate, Sub gate, Pin point gate, Edge gate etc |

| Mould Weight | 50kg-15Ton |

| Injection Machine Type | 80-1500Ton |

| Standard for Product Appearance for graining | MT(Mold Tech), YS, HN Series |

| The Way of Color Contrast for Plastic | RAL PANTONE |

| Certificated | ISO 9001:2015 Certificated, SGS Certificated |

Trade information:

| MOQ | 1 set |

| Mold lead time | T1 sample, about 3-10 weeks, according to the mold requirement |

| Production lead time | 2-5 weeks, according to the order Qty |

| Mold payment term | 50% T/T deposit with PO, balance 50% T/T after sample approved |

| Products payment term | 30% T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Ningbo or Shanghai port, also can be Shenzhen port |

Company Profile

Founded in 2010,we are OEM specialized in mold design & manufacture, injection molding and products assembling for more than 10 years with much experience.

The product rangs include automotive, electronic,electrical appliance,medical treatment,

communications and other other fields.

We have one group of outstanding mold engineers and advanced mold processing/manufacture equipment.

We are high technology enterprises with certification ISO9001

qualtiy system. Our mould and parts are mostly exported to

European,America,and other many countries for highly positive and

mutual trust.

KYD always adhere to the principles and objectives of high quality

of one-stop OEM or ODM services and good reputation. If any thing

we can do for you, any interest in our plastic injection moulding,

please feel free to contact us.

Looking forward to your visit and with long-term cooperation on the

basis of equality and mutual benefit!

Outdoor Scene

Mould Workshop

Injection Molding Workshop(20 injection machines)

Dustless Injection Workshop (3 injection machines)

Engineering Department

Packing Details : carton for mass production,wooden box for mould.

Delivery Details : 15-25 days when receiving money.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: Do you have the checking system to make sure the mould quality?

A: We have a complete management system. Our project dept. will arrange mould checking and supply the checking report in detail. Only when the mould is qualified, can the mould be shipped out.

Q: What are our Engineering capabilities included?

1. Parts design.

2. R&D products.

3. Prototype design and production assembly.

4. Reputable design software used for all design work.

5. Mould design.

6. Mould Manufacture.

Q:What is beneficial for you?

1. Free quotation for your comparison.

2. Design mould with price priority, easily processing and quality assurance.

3. Get a strategic long-term partner.

4. Get the best service.

Q: What should be provided to get price?

Samples , pictures with dimension , drawings and specific requirements.

Q:Can you make the mold and also supply us the injection molding plastic product?

A:Yes, we can make the mold and also help you to molding the plastic product for you.

Q:Can you make insert mold?

Yes, we can do this type mold, usual the insert material is metal insert, or hard plastic part, we have also experience to make 3color or material mold, we usual call this over mold.

Q:Can you make multi-cavity mold?

Yes, we can, we can build some molds with 16, 32 ,48cavities even more.

Q:Can you help us to improve the structure design?

Some customer have no experience on the mold technology, so the production usual need to improve the sturture to help save mold cost or improve the surface quality, yes we can help you on this.

Q: Can you help us to make the prototype and mold and molding product and painting or printing?

Yes, we can help the client from the prototype to the final product, we call this one-stop servise.