QINGDAO PERMIX MACHINERY CO., LTD |

|

Ceramic Materials Planetary Concrete Mixer PMC500 Wear - Resistant Alloy Plates

Hydraulic System Maintenance Instruction

1. Strictly follow the instruction to check the condition of the pump before use if the hydraulic pump has stopped for a long time;

2. Replace the oil and oil filter after running the first 100hours, then replace the oil or oil filter after 1000 hours running. From then on, replace oil or oil filter every 2000 hours.

3. When replace oil, clean oil tank and working components with new oil firstly then pour new oil

4. Check the bolts regularly and assure they are not loosen ;

Mixer advantages

The machine has the dual advantages of independent operation and the simple concrete mixing plant combined with PLD series batching machines. It can also provide matching hosts for the mixing station. It is suitable for all kinds of large, medium and small prefabricated component plants and highways and bridges. Water conservancy, docks and other industrial and civil construction projects are ideal for the host of concrete mixing plants. The product design structure is reasonable, the layout is novel, and it is easy to use and maintain. Users can use dump trucks and mixer trucks for their own use. At the same time, they can also be restructured according to the special requirements of users to meet their needs.

The use of mixer

1. Before use, the machine should have an empty test. Before the test machine, the firmness of all the connecting parts of the machine table shall be checked first, especially if the bearing part is loose during transportation. Close the main switch, access the power supply, run the empty test machine.

2. Empty machine test. The mixer can only be put into production without abnormal sound, high heat of bearing gear, etc.

3. If abnormal vibrations or strange sounds are detected during use, stop the mixer and give a thorough inspection.

4. The load should not be too large. It is generally measured by the load of the motor. The load current of the 380V motor when stirring the material should not exceed 6 amps. If it exceeds the load, the stirring capacity should be reduced immediately.

5. Managers should be familiar with the technical performance, internal structure, control structure, and operating principle of the mixer. Do not leave the workplace during operation to prevent malfunctions and damage to mechanical parts, so as to ensure

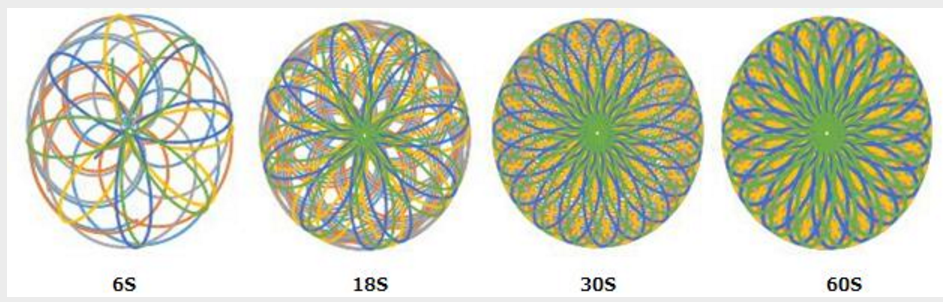

Principle of Motion: Mixing with no hidden corners in the mixing pan by installing mixing tools and scraper tools on a specially designed drive system. The mixing track as follows.

| Technical Data | ||||||||||||||

| PMC50 | PMC 100 | PMC 150 | PMC 250 | PMC 330 | PMC 500 | PMC 750 | PMC 1000 | PMC 1500 | PMC 2000 | PMC 2500 | PMC 3000 | PMC 4000 | PMC 4500 | |

| Output capacity(L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 4500 |

| Input capacity(L) | 75 | 225 | 375 | 500 | 750 | 1125 | 1500 | 2250 | 3000 | 3750 | 4500 | 6000 | 6750 | |

| Input capacity(kg) | 120 | 360 | 600 | 800 | 1200 | 1800 | 2400 | 3600 | 4800 | 6000 | 7200 | 9600 | 10800 | |

| Diameter of Mixing Tank(mm) | 1300 | 1540 | 1900 | 2192 | 2496 | 2796 | 3100 | 3400 | 3400 | |||||

| Mixing Power kw | 3 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 55 | 75 | 90 | 110 | 160 | 200 |

| Blade QTY | 1/2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*3 | 2*2 | 2*2 | 3*2 | 3/6 | 3/9 | 3/9 | 3/9 |

| Side Scraper QTY | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Bottom Scraper QTY | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Weight(kg) | 700 | 1000 | 1200 | 1700 | 2000 | 3500 | 6000 | 7000 | 8500 | 10500 | 11000 | 16000 | 18000 | |