Qingdao Huashida Machinery Co., Ltd. |

|

Verified Suppliers

|

|

| production range | processing capacity | Cleaning class | used material

|

| 159mm-1600mm | 159mm-1600mm | Sa2.5 | FBE powder, binder, polyethylene |

Huashida outside PE inside epoxy anticorrosive pipe production

equipment basic introduction

The anti-corrosion layer is crucial to the life of the buried

pipeline, the same material of the pipeline, some buried in the

ground for decades without corrosion, and some leakage occurs in a

few years, so the need for higher anti-corrosion technology for

pipeline anti-corrosion.

Pipeline anticorrosion production line composition

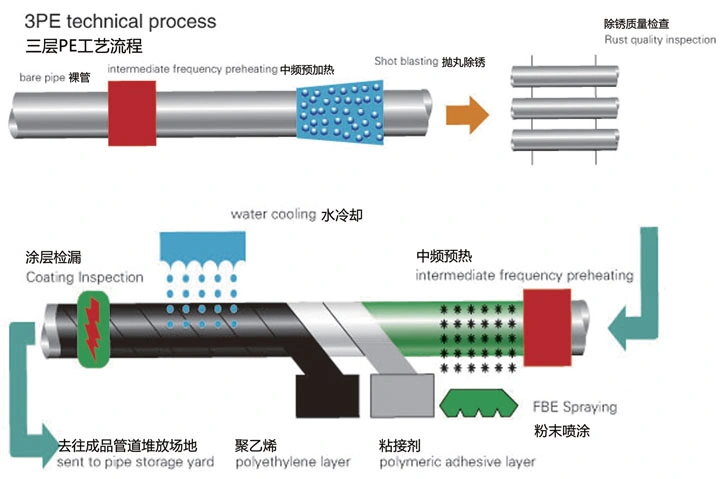

Huashida steel pipe anticorrosion production line is mainly

composed of loading bench, rust removal transmission line, steel

pipe preheating device, steel pipe shot blasting rust removal

equipment, intermediate bench, rust inspection platform, return

track, steel pipe internal purging device, coating transmission

line, pickling equipment, medium frequency heating equipment, epoxy

powder spraying device, polyethylene extruder, adhesive extruder,

centralized feeding system, water cooling system, and prevention

The rotten layer inspection platform, pipe end grinding equipment,

pipe exit table, linear roller table, automatic coding equipment

and the whole production line and corresponding equipment

pneumatic, hydraulic control system, electrical control system and

safety facilities.

Huashida outside PE inside epoxy anticorrosive pipe production

equipment effect

PE inside the epoxy anti-corrosion equipment, the inner layer of

epoxy powder, fundamentally ensure the anti-corrosion effect of the

anti-corrosion steel pipe, and then carry out the next process: The

adhesive three-layer structure polyethylene anticorrosion layer

combines the excellent properties of fused epoxy powder coating and

extruded polyethylene anticorrosion layer, and combines the

interface characteristics and chemical resistance characteristics

of fused epoxy powder coating with the mechanical protection

characteristics of extruded polyethylene anticorrosion layer to

improve their respective properties. Therefore, it is very superior

as the outer protective layer of the buried pipeline.

advantage

1, 3pe anticorrosive steel pipe has very high sealing, long-term

operation can greatly save energy, reduce costs, protect the

environment.

2, the construction is simple and fast, and the service life can

reach 30-50 years.

3, also has good impact resistance under low temperature

conditions, PE water absorption is low.

4, at the same time with high epoxy strength, PE low water

absorption and hot melt adhesive softness, has a high

anti-corrosion reliability, this anti-corrosion is characterized by

simple production process, good anti-corrosion effect, low price,

is the pipeline manufacturing industry generally recognized

anti-corrosion method 2, oil and gas with three layers of

polyethylene (3PE) steel pipe anti-corrosion, two layers of

polyethylene (2PE) steel pipe anti-corrosion.