Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

BS4504 PN 6 Code 112 Carbon Steel and Stainless Steel Slip On Flanges SORF for Industrial Purposes

Introduction:

With a solid track record spanning over two decades, Shaanxi Peter International Trade Co., Ltd. has built a strong reputation as a leading supplier in the market. Our expertise lies in providing BS4504 Carbon Steel and Stainless Steel Slip On Flanges to meet the diverse needs of our customers.

Recognizing the significance of delivering high-quality products, we go above and beyond to ensure meticulous material selection and strict adherence to quality control processes at every stage of manufacturing and inspection. Our slip on flanges, crafted with precision, fully comply with BS4504 standards, guaranteeing reliability and durability across various industrial applications.

We cater to a wide range of industries, including shipbuilding, power generation, petrochemical plants, oil refineries, wastewater treatment plants, paper mills, pharmaceutical plants, and turnkey projects.

Description of BS4504 Slip On Flanges:

BS4504 slip on flanges are indeed a popular type of pipe flange that offers advantages in certain applications. They are designed to allow the pipe to slide into the bore or center of the flange, enabling welding around the outer diameter (OD) of the pipe and on the interior side of the connection.

One of the key benefits of BS4504 slip on flanges is their flexibility in adjusting the length of the pipe relative to the flange position. Unlike weld neck flanges, BS4504 slip on flanges do not have a weld bevel, providing more freedom in pipe length adjustments. The bore of the BS4504 slip on flange provides sufficient space for the pipe to fit, allowing ample working space for the welder and fabricator during the connection process.

BS4504 slip on flanges are commonly used in lower pressure applications and often feature a hub that resembles the dimensions of a raised face flange. However, they can also be supplied without a hub in cases where space is limited and a "ring style" slip-on is suitable. It's worth noting that slip-ons in higher pressure classes may adopt the height of a lap joint for a stronger connection. In situations where the hub height is not a concern and a lap joint style flange is not readily available, customers may opt for a slip on flange made to a lap joint style with a machined hub.

BS4504 slip on flanges provide a straightforward and practical solution for joining pipes in various applications. Their adaptability, ease of installation, and availability in different configurations make them a popular choice for many piping systems.

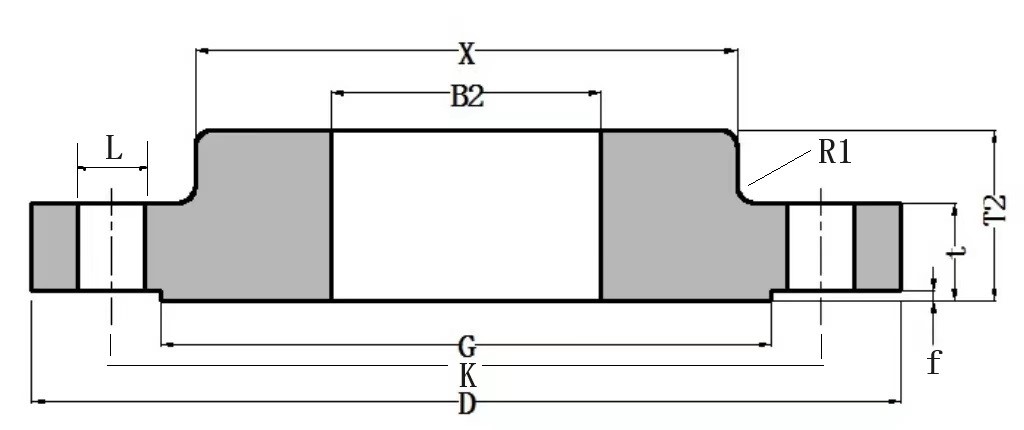

BS4504 Code 112 Slip On Flange Dimensions:

| BS4504 CODE 112 Slip On Flanges PN 6 SORF | ||||||||||||

| DN | Outside Diameter | O.D.of Raised Face |

Height of Raised Face | Neck Diameter | Thickness | Dia Counter Bore | Length of Flange | Bolt circle diameter | Number of holes | Diameter of Bolt |

Radius of Corners

|

Weight

|

| D | G | f | X | t | B2 | T2 | K | Numbers | L | R1 | KG | |

| 10 | 75 | 35 | 2 | 25 | 12 | 18.0 | 20 | 50 | 4 | 11 | 3 | 0.3 |

| 15 | 80 | 40 | 2 | 30 | 12 | 22.0 | 20 | 55 | 4 | 11 | 3 | 0.4 |

| 20 | 90 | 50 | 2 | 40 | 14 | 27.5 | 24 | 65 | 4 | 11 | 4 | 0.6 |

| 25 | 100 | 60 | 2 | 50 | 14 | 34.5 | 24 | 75 | 4 | 11 | 4 | 0.7 |

| 32 | 120 | 70 | 2 | 60 | 14 | 43.5 | 26 | 90 | 4 | 14 | 5 | 1.0 |

| 40 | 130 | 80 | 3 | 70 | 14 | 49.5 | 26 | 100 | 4 | 14 | 5 | 1.2 |

| 50 | 140 | 90 | 3 | 80 | 14 | 61.5 | 28 | 110 | 4 | 14 | 5 | 1.3 |

| 65 | 160 | 110 | 3 | 100 | 14 | 77.5 | 32 | 130 | 4 | 14 | 6 | 1.8 |

| 80 | 190 | 128 | 3 | 110 | 16 | 90.5 | 34 | 150 | 4 | 18 | 6 | 2.7 |

| 100 | 210 | 148 | 3 | 130 | 16 | 116.0 | 40 | 170 | 4 | 18 | 6 | 3.0 |

| 125 | 240 | 178 | 3 | 160 | 18 | 141.5 | 44 | 200 | 8 | 18 | 6 | 4.4 |

| 150 | 265 | 202 | 3 | 185 | 18 | 170.5 | 44 | 225 | 8 | 18 | 8 | 4.6 |

| 200 | 320 | 258 | 3 | 240 | 20 | 221.5 | 44 | 280 | 8 | 18 | 8 | 6.9 |

| 250 | 375 | 312 | 3 | 295 | 22 | 276.5 | 44 | 335 | 12 | 18 | 10 | 8.9 |

| 300 | 440 | 365 | 4 | 355 | 22 | 327.5 | 44 | 395 | 12 | 22 | 10 | 12.1 |

| 350 | 490 | 415 | 4 | - | 22 | 359.5 | - | 445 | 12 | 22 | 10 | - |

| 400 | 540 | 465 | 4 | - | 22 | 411.0 | - | 495 | 16 | 22 | 10 | - |

| 450 | 595 | 520 | 4 | - | 24 | 462.0 | - | 550 | 16 | 22 | 12 | - |

| 500 | 645 | 570 | 4 | - | 24 | 513.5 | - | 600 | 20 | 22 | 12 | - |

| 600 | 755 | 670 | 5 | - | 24 | 616.5 | - | 705 | 20 | 26 | 12 | - |

| 700 | 860 | 775 | 5 | - | 24 | - | - | 810 | 24 | 26 | 12 | - |

| 800 | 975 | 880 | 5 | - | 24 | - | - | 920 | 24 | 30 | 12 | - |

| 900 | 1075 | 980 | 5 | - | 26 | - | - | 1020 | 24 | 30 | 12 | - |

| 1000 | 1175 | 1080 | 5 | - | 26 | - | - | 1120 | 28 | 30 | 12 | - |

| 1200 | 1405 | 1295 | 5 | - | 28 | - | - | 1340 | 32 | 33 | 12 | - |

| 1400 | 1630 | 1510 | 5 | - | 32 | - | - | 1560 | 36 | 36 | 12 | - |

| 1600 | 1830 | 1710 | 5 | - | 34 | - | - | 1760 | 40 | 36 | 12 | - |

| 1800 | 2045 | 1920 | 5 | - | 36 | - | - | 1970 | 44 | 39 | 15 | - |

| 2000 | 2265 | 2125 | 5 | - | 38 | - | - | 2180 | 48 | 42 | 15 | - |

1.Dimensions are in millimeters(mm).

2.Dimensions can be specified by different purchasers.

Materials of BS4504 Slip On Flanges:

BS4504 slip on flanges are available in various materials to suit different applications and operating conditions. The material selection for BS4504 slip on flanges depends on factors such as temperature, pressure, corrosion resistance, and compatibility with the conveyed fluid or gas.

Grades of Carbon Steel Slip On Flanges:

ASTM A105: This is a common grade of carbon steel used for slip on flanges. It is a forged carbon steel specifically designed for high-temperature service and offers excellent weldability and toughness.

ASTM A350 LF2: LF2 is a low-temperature carbon steel grade commonly used for slip on flanges in applications where low-temperature toughness is required.

ASTM A694 F52/F60/F65/F70: These grades are high-yield carbon steel materials used for slip on flanges in applications requiring high strength and impact resistance.

Grades of Stainless Steel Slip On Flanges:

ASTM A182 F304/F304L: These grades of stainless steel are austenitic and commonly used for slip on flanges. They offer good corrosion resistance, excellent weldability, and are suitable for a wide range of applications.

ASTM A182 F316/F316L: Similar to F304/F304L, these grades are also austenitic stainless steels with improved corrosion resistance, particularly in chloride environments.

ASTM A182 F321: F321 is an austenitic stainless steel grade containing titanium, which provides enhanced resistance to intergranular corrosion. It is often used for slip on flanges in high-temperature applications.

ASTM A182 F347: F347 is a stabilized stainless steel grade with the addition of niobium, which improves its resistance to intergranular corrosion. It is commonly used for weld neck flanges in applications involving elevated temperatures.

Advantages of BS4504 Slip On Flanges:

Easy Installation: Slip on flanges are relatively easy to install compared to other types of flanges. Their design allows them to slide over the pipe, making alignment and welding processes more convenient and efficient. This ease of installation can save time and labor costs during the assembly of piping systems.

Cost-Effective: Slip on flanges are generally more cost-effective compared to other types of flanges. They require less material and machining compared to weld neck flanges or socket weld flanges, making them a more economical option.

Versatility: Slip on flanges are versatile and can be used in a wide range of applications and industries. They are suitable for low-pressure and moderate-temperature environments, making them a popular choice for general-purpose applications.

Welding Convenience: Slip on flanges provide ample space for welding. The fillet weld connection provided by slip on flanges is relatively simpler to execute compared to the weld bevel connection required by weld neck flanges. This makes slip on flanges a preferred choice when efficient welding is desired.

Flexibility in Pipe Length Adjustment: Slip on flanges do not have a weld bevel, allowing for pipe length adjustment relative to the flange position. This flexibility can be advantageous in situations where pipe length needs to be adjusted or where thermal expansion and contraction of the piping system need to be accommodated.

Lower Risk of Welding Defects: Slip on flanges require a fillet weld, which is generally easier to achieve and has a lower risk of welding defects compared to the butt weld used in weld neck flanges. This can contribute to improved weld quality and reduced rework or repairs.

Applications of BS4504 Carbon Steel and Stainless Steel Slip On Flanges:

Oil and Gas Industry: Carbon steel and stainless steel slip on flanges are commonly used in the oil and gas industry for various applications such as pipelines, refineries, and petrochemical plants. They are suitable for low to moderate pressure and temperature environments.

Power Generation: Carbon steel and stainless steel slip on flanges find application in power generation facilities, including power plants and thermal power stations. They are used for connecting pipes in steam, water, or gas distribution systems.

Water and Wastewater Treatment: Carbon steel and stainless steel slip on flanges are utilized in water treatment plants, wastewater treatment facilities, and desalination plants. They provide secure connections for pipes carrying water, chemicals, or other fluids.

Construction and Infrastructure: Carbon steel and stainless steel slip on flanges are widely used in construction projects such as buildings, bridges, and infrastructure. They are suitable for connecting pipes in HVAC systems, plumbing, and fire protection systems.

Industrial Processes: Carbon steel and stainless stel slip on flanges are employed in various industrial processes, including manufacturing, chemical processing, and mining. They are used to connect pipes in conveying fluids, gases, or abrasive materials.

Food and Beverage Industry: Carbon steel and stainless steel slip on flanges are commonly used in the food and beverage industry due to their hygienic properties and resistance to corrosion. They are suitable for connecting pipes in processing, bottling, and storage systems.

Pharmaceuticals: Carbon Steel and stainless steel slip on flanges are utilized in pharmaceutical manufacturing facilities where cleanliness and hygiene are critical. They are used for connecting pipes in drug production, purification, and distribution systems.

Chemical Processing: Carbon Steel and stainless steel slip on flanges find application in chemical processing plants where resistance to corrosion and chemical compatibility are essential. They are used for connecting pipes carrying corrosive chemicals, acids, or solvents.