Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

ANSI/ASME B16.5 Carbon Steel Weld Neck Flanges Class 600LB WNRF

Introduction:

Our company Shaanxi Peter International Trade Co., Ltd. is a highly regarded company with a strong presence in the industry, boasting over two decades of experience. Our expertise lies in the production of top-quality ASME B16.5 Class 600 weld neck flanges, renowned for their exceptional reliability, durability, and outstanding performance.

Our weld neck flanges are meticulously manufactured to meet the stringent standards set by the ASME B16.5 specification. This ensures that our products comply with rigorous specifications and quality requirements. By adhering to these industry standards, we guarantee that our weld neck flanges will exceed your expectations and deliver optimal performance in various applications.

At Shaanxi Peter International Trade Co., Ltd., we prioritize customer satisfaction above all else. We understand the importance of providing reliable and durable products that meet the diverse needs of our clients. Our dedicated team of professionals works tirelessly to ensure that every weld neck flange leaving our facility meets the highest quality standards.

We pride ourselves on our commitment to continuous improvement and innovation. Our manufacturing process incorporates advanced technologies and techniques to ensure precise dimensions, excellent surface finishes, and superior corrosion resistance. By investing in state-of-the-art equipment and employing skilled technicians, we can guarantee the consistent quality of our ASME B16.5 Class 600 weld neck flanges.

ANSI/ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges:

The ANSI/ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges are widely used in piping systems to provide a strong and durable connection between pipes or valves. These flanges are designed and manufactured in accordance with the standards set by the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME).

ANSI/ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges are a specific type of flange that meets the dimensional and material requirements set by the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) for Class 600 flanges.

Here are some key features of ANSI/ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges:

Design: These flanges have a weld neck design, which means they have a long tapered hub with a circular rim that provides reinforcement and allows for easy welding to the pipe.

Material: ANSI/ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges are made from carbon steel, which is known for its strength, durability, and resistance to corrosion. Carbon steel is commonly used in various industrial applications due to its excellent mechanical properties.

Pressure Rating: These flanges have a pressure rating of 600 pounds per square inch (PSI), making them suitable for high-pressure applications.

Size Range: ANSI/ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges are available in a range of sizes, typically from 1/2 inch up to 24 inches or larger, depending on the specific requirements of the application.

Dimensions and Tolerances: These flanges follow the dimensions and tolerances specified in the ANSI/ASME B16.5 standard. This includes parameters such as outside diameter, overall height, bolt hole spacing, flange thickness, and other critical dimensions to ensure proper fit and compatibility with other components in the piping system.

Flange Facing: The flange facing for ANSI/ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges typically follows the standard Raised Face (RF) or Ring Type Joint (RTJ) facing. This provides a reliable sealing surface for gaskets, ensuring effective sealing between flanges.

Testing and Certification: To ensure the quality and performance of these flanges, they may undergo various tests, such as hydrostatic testing, visual inspection, and dimensional checks. Manufacturers may provide certification documents, such as mill test reports, to verify compliance with the required standards.

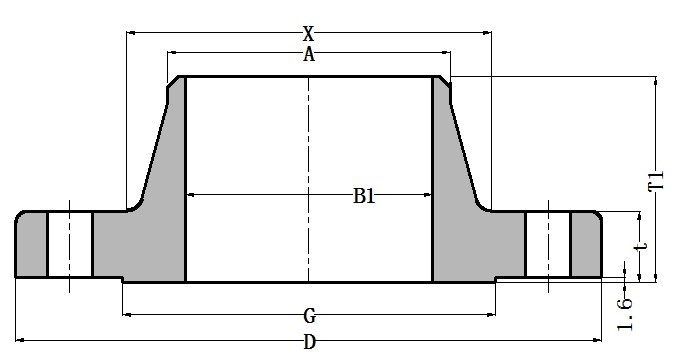

ANSI/ASME B16.5 Weld Neck Flange Dimensions:

| ANSI/ASME B16.5 Class 600 WELD NECK FLANGES WNRF | |||||||||||

| Nominal Pipe size | Outside Diameter | O.D.of Raised Face | Diameter at base of Hub | Thickness | Bore | Length | Dia of Hub Top | Drilling | Weight (lb) | ||

| D | G | X | t | B1 | T1 | A | Bolt Circle Dia | Number of holes | Dia of holes | ||

| 1/2'' | 95 | 35.1 | 38.1 | 14.2 | 52.3 | 21.3 | 66.5 | 4 | 15.7 | 3 | |

| 3/4'' | 117 | 42.9 | 47.8 | 15.7 | 57.2 | 26.7 | 82.6 | 4 | 19.1 | 4 | |

| 1'' | 124 | 50.8 | 53.8 | 17.5 | 62 | 33.5 | 88.9 | 4 | 19.1 | 4 | |

| 1.1/4'' | 133 | 63.5 | 63.5 | 20.6 | 66.5 | 42.2 | 98.6 | 4 | 19.1 | 6 | |

| 1.1/2'' | 155 | 73.2 | 69.9 | 22.4 | 69.9 | 48.3 | 114.3 | 4 | 22.4 | 8 | |

| 2'' | 165 | 91.9 | 84.1 | 25.4 | 73.2 | 60.5 | 127 | 8 | 19.1 | 12 | |

| 2.1/2'' | 191 | 104.6 | 100.1 | 28.4 | 79.2 | 73.2 | 149.4 | 8 | 22.4 | 18 | |

| 3'' | 210 | 127 | 117.3 | 31.8 | 82.6 | 88.9 | 168.1 | 8 | 22.4 | 23 | |

| 3.1/2'' | 229 | 139.7 | 133.4 | 35.1 | 85.9 | 101.6 | 184.2 | 8 | 25.4 | 26 | |

| 4'' | 273 | 157.2 | 152.4 | 38.1 | 101.6 | 114.3 | 215.9 | 8 | 25.4 | 42 | |

| 5'' | 330 | 185.7 | 189 | 44.5 | 114.3 | 141.2 | 266.7 | 8 | 28.4 | 68 | |

| 6'' | 356 | 215.9 | 222.3 | 47.8 | 117.3 | 168.4 | 292.1 | 12 | 28.4 | 81 | |

| 8'' | 419 | 269.7 | 273.1 | 55.6 | 133.4 | 219.2 | 349.3 | 12 | 31.8 | 120 | |

| 10'' | 508 | 323.9 | 342.9 | 63.5 | 152.4 | 273.1 | 431.8 | 16 | 35.1 | 190 | |

| 12'' | 559 | 381 | 400.1 | 66.7 | 155.4 | 323.9 | 489 | 20 | 35.1 | 226 | |

| 14'' | 603 | 412.8 | 431.8 | 69.9 | 165.1 | 355.6 | 527.1 | 20 | 38.1 | 347 | |

| 16'' | 686 | 469.9 | 495.3 | 76.2 | 177.8 | 406.4 | 603.3 | 20 | 41.1 | 481 | |

| 18'' | 743 | 533.4 | 546.1 | 82.6 | 184.2 | 457.2 | 654.1 | 20 | 44.5 | 555 | |

| 20'' | 813 | 584.2 | 609.6 | 88.9 | 190.5 | 508 | 723.9 | 24 | 44.5 | 690 | |

| 22’’ | 870 | 641.1 | 666.8 | 95.3 | 196.9 | 558.8 | 778 | 24 | 44.5 | 720 | |

| 24'' | 940 | 692.2 | 717.6 | 101.6 | 203.2 | 609.6 | 838.2 | 24 | 50.8 | 977 | |

1.Dimensions are in millimeters(mm).

2.B1 can be specified by different purchasers.

3.For sizes 1/2’’-3.1/2’’, Dimensions of ASME B16.5 Class 600 Weld Neck Flanges are the same as ASME B16.5 Class 400 Weld Neck Flanges.

Features of Carbon Steel Weld Neck Flanges:

A weld neck flange is a type of pipe flange that has a long, tapered neck and a hub. It is designed to be butt-welded to the pipe or fitting, providing a strong and leak-free connection. The primary purpose of a weld neck flange is to join pipes or fittings together in a piping system.

The key features of a weld neck flange include:

Neck: The neck of the flange has a gradual taper that helps to distribute stress and reduce the concentration of stress at the weld joint. This design provides increased strength and structural integrity.

Hub: The hub of the flange acts as an extension of the pipe, allowing for a smooth transition and improved flow efficiency. It also provides reinforcement and additional strength to the joint.

Welding Bevel: The welding bevel is the edge preparation on the flange where the weld joint is made. It is usually prepared with a specific angle to facilitate proper welding and ensure a strong and reliable connection.

Raised Face: Weld neck flanges often have a raised face around the flange's sealing surface. This raised face helps create a better seal when the flange is bolted to another flange or equipment.

Weld neck flanges are commonly used in high-pressure and high-temperature applications, where the strength and integrity of the connection are crucial. They are widely employed in industries such as oil and gas, petrochemical, chemical processing, power generation, and water treatment.

Advantages of Carbon Steel Weld Neck Flanges:

Carbon steel weld neck flanges offer several advantages that make them a popular choice in various industries:

Strength and Durability: Carbon steel is known for its high strength and durability, making it an excellent material for weld neck flanges. These flanges can withstand high-pressure applications and provide long-lasting performance.

Corrosion Resistance: Carbon steel can be alloyed with other elements to enhance its resistance to corrosion. This makes carbon steel weld neck flanges suitable for use in environments where exposure to moisture, chemicals, or harsh conditions may occur.

Easy Welding and Installation: Weld neck flanges have a tapered hub and a beveled end, which allows for easy alignment and welding to the pipe. This design ensures a strong and secure connection, reducing the risk of leaks or failures.

Superior Sealing: The weld neck flange design provides a smooth transition from the flange to the pipe, resulting in better sealing capabilities. This helps prevent leakage and ensures efficient flow of fluids or gases.

Excellent Flow Characteristics: The long tapered hub of weld neck flanges promotes smooth fluid flow and minimizes turbulence. This improves overall system performance and reduces pressure drop.

Versatility: Carbon steel weld neck flanges are available in a wide range of sizes, pressure ratings, and specifications, making them suitable for various piping systems and applications. They can be used in industries such as oil and gas, petrochemical, power generation, water treatment, and more.

Cost-Effective: Carbon steel is a cost-effective material compared to other alloys, making carbon steel weld neck flanges a budget-friendly option for many projects.

Applications of ASME B16.5 Class 600 Carbon Steel Weld Neck Flanges:

Carbon steel weld neck flanges are a common type of pipeline connection component made from carbon steel. They have many advantages, such as high strength, good corrosion resistance, and relatively low price. Carbon steel weld neck flanges are widely used in many different application areas, including the following:

Petroleum and gas industry: Carbon steel weld neck flanges are commonly used in pipeline systems for transporting oil and gas. These pipelines typically transport liquids or gases at high pressures and temperatures, so they require good pressure resistance and sealing performance. Carbon steel weld neck flanges can meet these requirements and are suitable for various oil and gas exploration, processing, and transportation environments.

Chemical industry: In the chemical industry, carbon steel weld neck flanges are widely used to connect pipelines in various chemical production and processing processes. These processes may involve corrosive media, high temperature, or high pressure conditions, so materials need to have good corrosion resistance and pressure resistance. The corrosion resistance of carbon steel weld neck flanges and their compatibility with other pipeline materials make them a common choice in the chemical industry.

Power plants: Carbon steel weld neck flanges are used in power plants to connect key equipment such as boilers, steam pipes, and cooling water systems. These systems typically face high temperature and pressure conditions and require reliable pipeline connections to ensure safe and efficient operation. Carbon steel weld neck flanges can meet these requirements and are widely used in thermal power plants, nuclear power plants, and other types of power plants.

Manufacturing industry: In the manufacturing industry, carbon steel weld neck flanges are commonly used to connect pipelines in various industrial equipment and machinery. These devices may include chemical equipment, food processing equipment, papermaking machinery, etc. Carbon steel weld neck flanges provide a reliable connection method, can withstand high pressures and temperatures, and meet the needs of the manufacturing process.

Carbon steel weld neck flanges are pipeline connection components widely used in various industries. They play important roles in the petroleum and gas industry, chemical industry, power plants, and manufacturing industry, providing reliable pipeline connection solutions.