Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

ANSI B16.47 SERIES B Class 600 Carbon Steel Weld Neck Flanges and Blind Flanges

Introduction:

We are Shaanxi Peter International Trade Co., Ltd., a reputable and well-established company of rich experience in the industry. As your reliable supplier, we have been providing high-quality ANSI B16.47 SERIES B FLANGES for more than 20 years in the industry.

Our ANSI B16.47 SERIES B FLANGES are designed to meet the specifications of ASME B16.47 and are made of durable materials, ensuring their high strength and resistance to corrosion.

We prioritize customer satisfaction above all else. We understand the importance of providing reliable and durable products that meet the diverse needs of our clients. Our dedicated team of professionals works tirelessly to ensure that every weld neck flange leaving our facility meets the highest quality standards.Our manufacturing process incorporates advanced technologies and techniques to ensure precise dimensions, excellent surface finishes, and superior corrosion resistance.

Descriptions of ANSI/ASME B16.47 SERIES B Weld Neck Flanges and Blind Flanges:

In November 1980, Subcommittee C of the American Society of Mechanical Engineers (ASME) B16 began the development of the Large Diameter Steel Flange Standard. The purpose was to establish uniform dimensions, tolerances, markings, and materials for flanges with Nominal Pipe Sizes (NPS) ranging from 26 inches to 60 inches. This standard aimed to provide consistency and compatibility in the industry.

Prior to the development of the Large Diameter Steel Flange Standard, in July 1952, the Manufacturers Standardization Society (MSS) released MSS-SP44. MSS-SP44 covered flanges for NPS 12 inches to 60 inches with pressure ratings ranging from 150# to 900#. It included various facing configurations such as raised face (RF), flat face (FF), and ring type joint (RTJ).

The initial draft of the Large Diameter Steel Flange Standard was formulated in December 1982. It underwent several revisions and modifications to ensure accuracy and effectiveness. Finally, in 1990, the standard was approved and published. The final version of the standard duplicated the specifications outlined in MSS-SP44 and replaced the API-605 specification.

The Large Diameter Steel Flange Standard consists of two series: Series A and Series B. Both series focus exclusively on weld neck and blind flange specifications. These flanges are available in different materials, including carbon steel, stainless steel, and other alloy materials. The standard aims to provide a comprehensive set of guidelines for large diameter steel flanges, ensuring consistency, reliability, and safety in various industrial applications.

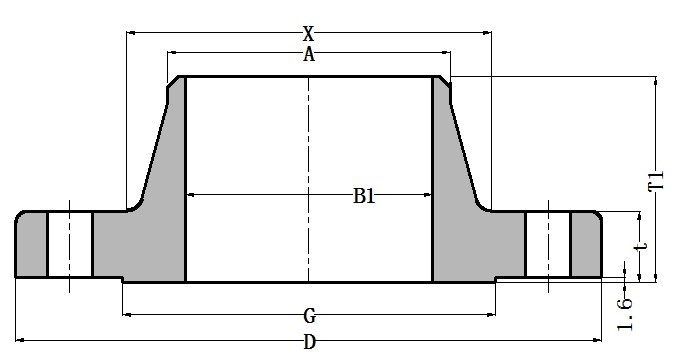

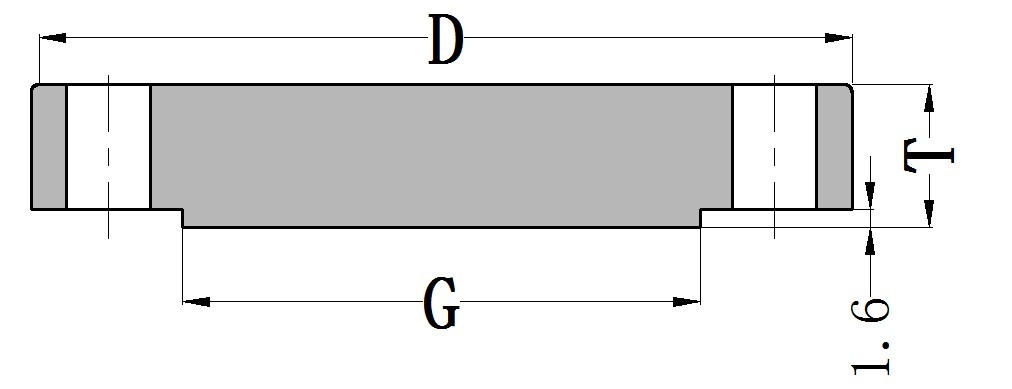

ANSI B16.47 SERIES B Weld Neck Flanges and Blind Flanges Dimensions:

| ANSI/ASME B16.47 SERIES B CLASS 600 | |||||||||||||

| Nominal Pipe size | Outside Diameter | O.D.of Raised Face | Diameter at base of Hub | Thickness | Bore | Length | Dia of Hub Top | Drilling | Weight (lb) | ||||

| D | G | X | t/T | B1 | T1 | A | Bolt Circle Dia | Number of holes | Dia of holes | Weld Neck | Blind | ||

| 26 | 889.0 | 726.9 | 698.5 | 111.3 | 111.3 | 180.8 | 660.4 | 806.5 | 28 | 44.5 | 550 | 1194 | |

| 28 | 952.5 | 784.4 | 752.3 | 115.8 | 115.8 | 190.5 | 711.2 | 863.6 | 28 | 47.8 | 650 | 1427 | |

| 30 | 1022.4 | 841.2 | 806.5 | 125.5 | 127.0 | 204.7 | 762.0 | 927.1 | 28 | 50.8 | 810 | 1802 | |

| 32 | 1085.9 | 895.4 | 860.6 | 130.0 | 134.9 | 215.9 | 812.8 | 984.3 | 28 | 53.8 | 950 | 2159 | |

| 34 | 1155.7 | 939.8 | 914.4 | 142.2 | 147.3 | 233.4 | 863.6 | 1054.1 | 24 | 60.5 | 1205 | 2645 | |

| 36 | 1212.9 | 1009.7 | 968.2 | 146.1 | 150.9 | 242.8 | 914.4 | 1104.9 | 28 | 60.5 | 1340 | 3013 | |

| 38 | 1270.0 | 1054.1 | 1022.4 | 152.4 | 155.4 | 254.0 | 965.2 | 1162.1 | 28 | 60.5 | 1470 | 3404 | |

| 40 | 1320.8 | 1111.3 | 1073.2 | 158.8 | 162.1 | 263.7 | 1016.0 | 1212.9 | 32 | 60.5 | 1630 | 3838 | |

| 42 | 1403.4 | 1168.4 | 1127.3 | 168.1 | 171.5 | 279.4 | 1066.8 | 1282.7 | 28 | 66.5 | 2030 | 4585 | |

| 44 | 1454.2 | 1225.6 | 1181.1 | 173.0 | 177.8 | 289.1 | 1117.6 | 1333.5 | 32 | 66.5 | 2160 | 5105 | |

| 46 | 1511.3 | 1276.4 | 1234.9 | 179.3 | 185.7 | 300.0 | 1168.4 | 1390.7 | 32 | 66.5 | 2410 | 5758 | |

| 48 | 1593.9 | 1333.5 | 1289.1 | 189.0 | 195.3 | 316.0 | 1219.2 | 1460.5 | 32 | 73.2 | 2855 | 6737 | |

| 50 | 1670.1 | 1384.3 | 1343.2 | 196.9 | 203.2 | 328.7 | 1270.0 | 1524.0 | 28 | 79.2 | 3330 | 7695 | |

| 52 | 1720.9 | 1435.1 | 1394.0 | 203.2 | 209.6 | 336.6 | 1320.8 | 1574.8 | 32 | 79.2 | 3560 | 8426 | |

| 54 | 1778.0 | 1492.3 | 1447.8 | 209.6 | 217.4 | 349.3 | 1371.6 | 1632.0 | 32 | 79.2 | 3920 | 9333 | |

| 56 | 1854.2 | 1543.1 | 1501.6 | 217.4 | 225.6 | 362.0 | 1422.4 | 1695.5 | 32 | 85.9 | 4280 | 10,529 | |

| 58 | 1905.0 | 1600.2 | 1552.4 | 222.3 | 231.6 | 369.8 | 1473.2 | 1746.3 | 32 | 85.9 | 4640 | 11,414 | |

| 60 | 1993.9 | 1657.4 | 1609.9 | 233.4 | 242.8 | 388.9 | 1524.0 | 1822.5 | 28 | 91.9 | 5000 | 13,108 | |

1.Dimensions are in millimeters(mm).

2.B1 can be specified by different purchasers.

Advantages of ASME B16.47 Weld Neck Flanges and Blind Flanges:

Advantages of ASME B16.47 Weld Neck Flanges:

Strong and Reliable Connection: Weld neck flanges provide a strong and reliable connection between the pipe and the flange. The welding process ensures a secure joint that can withstand high pressure, temperature, and mechanical stresses.

Enhanced Structural Integrity: The long tapered hub of a weld neck flange provides reinforcement to the connection, making it more resistant to bending, flexing, and deformation. This enhances the overall structural integrity of the system.

Improved Flow Characteristics: The smooth transition from the flange bore to the pipe bore in a weld neck flange minimizes flow turbulence and pressure drop. This results in improved flow characteristics, reduced energy loss, and enhanced system efficiency.

Sealing Capability: Weld neck flanges typically feature a raised face or ring joint face configuration, which allows for effective sealing using gaskets. This helps prevent leakage and ensures a tight seal, especially in high-pressure or critical applications.

Advantages of ASME B16.47 Blind Flanges:

Pipeline Closure: Blind flanges are specifically designed to seal the end of a pipeline. They provide a solid barrier, preventing the flow of fluids or gases through the pipeline when needed. This is particularly useful during maintenance, testing, or shutdowns.

System Integrity and Safety: By sealing off the pipeline, blind flanges help maintain the integrity and safety of the system. They prevent the ingress of foreign materials, protect against contamination, and minimize the risk of leaks or spills.

Pressure Containment: Blind flanges are capable of withstanding high internal pressures within the pipeline. They provide a robust closure that can handle the pressure load, ensuring the safe operation of the system.

Versatility: Blind flanges can be used in various applications and industries. They are suitable for both temporary and permanent closures and can be easily installed or removed as needed.

Differences between ASME B16.5 and ASME B16.47 Flanges:

The main differences between ASME B16.5 and ASME B16.47 are as follows:

Size Range: ASME B16.5 covers flanges with a nominal pipe size ranging from ¼ inches to 24 inches. It is commonly used for smaller to medium-sized pipe connections. On the other hand, ASME B16.47 is specifically designed for larger diameter flanges, typically starting from 26 inches and going up to 60 inches.

Flange Types: ASME B16.5 includes various flange types such as weld neck, slip-on, threaded, socket weld, and blind flanges. It offers a wider range of options to suit different applications. ASME B16.47, on the other hand, primarily focuses on weld neck and blind flanges. Series A of ASME B16.47 also includes slip-on and threaded flanges.

Flange Face Configurations: ASME B16.5 provides options for raised face and flat face flange configurations. It is more commonly associated with raised face flanges. ASME B16.47, particularly Series A, includes raised face and ring joint face configurations. Series B of ASME B16.47 includes flat face flanges.

Weight and Dimensions: ASME B16.47 flanges, especially Series A, are generally heavier and have larger dimensions compared to ASME B16.5 flanges. The larger size and weight of ASME B16.47 flanges are suitable for heavy-duty applications and high-pressure systems.

Pressure Classes: ASME B16.5 flanges cover pressure classes ranging from 150 to 2500, accommodating a wide range of pressure requirements. ASME B16.47 also offers different pressure classes, but it is more commonly associated with higher pressure classes due to its focus on larger diameter and heavy-duty applications.

Applications of ASME B16.47 Series B Carbon Steel Weld Neck Flanges and Blind Flanges:

ASME B16.47 Carbon Steel Weld Neck Flanges and Blind Flanges, whether in Series A or Series B, have several applications across various industries.

Oil and Gas Industry: Weld Neck Flanges and Blind Flanges are extensively used in the oil and gas industry for pipeline connections, storage tanks, and refineries. They provide a secure and leak-proof connection for high-pressure and high-temperature applications.

Petrochemical Industry: ASME B16.47 Carbon Steel Flanges are widely employed in petrochemical plants for connecting pipes, valves, and equipment. They ensure reliable and durable connections in processing units, such as distillation columns, reactors, and heat exchangers.

Power Generation: Weld Neck and Blind Flanges are utilized in power plants, including thermal power plants, nuclear power plants, and renewable energy facilities. They are used in pipeline systems, steam turbines, boilers, and other equipment, providing robust connections in demanding operating conditions.

Chemical Industry: Carbon Steel Flanges find applications in the chemical industry for handling corrosive fluids and chemicals. They are used in chemical processing plants, storage tanks, and transportation systems, ensuring the safe and efficient flow of various substances.

Water and Wastewater Treatment: ASME B16.47 Flanges are employed in water treatment facilities, wastewater treatment plants, and desalination plants. They are used for connecting pipes, valves, and pumps, providing secure and leak-free connections in water distribution and treatment systems.

Mining and Minerals: Carbon Steel Flanges are utilized in mining operations for transporting minerals, ores, and slurries. They are employed in pipelines, crushers, conveyors, and other equipment, enabling efficient material handling and processing.

Construction and Infrastructure: Weld Neck and Blind Flanges are used in construction projects and infrastructure development, including buildings, bridges, and pipelines. They ensure reliable connections in plumbing systems, HVAC systems, and water supply networks.