Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

ANSI B16.47 SERIES B Class 75 Carbon Steel Weld Neck Flanges and Blind Flanges

Introduction:

We are Shaanxi Peter International Trade Co., Ltd., a reputable and well-established company of rich experience in the industry. As your reliable supplier, we have been providing high-quality ANSI B16.47 SERIES B FLANGES for more than 20 years in the industry.

Our ANSI B16.47 SERIES B FLANGES are designed to meet the specifications of ASME B16.47 and are made of durable materials, ensuring their high strength and resistance to corrosion.

We prioritize customer satisfaction above all else. We understand the importance of providing reliable and durable products that meet the diverse needs of our clients. Our dedicated team of professionals works tirelessly to ensure that every weld neck flange leaving our facility meets the highest quality standards.Our manufacturing process incorporates advanced technologies and techniques to ensure precise dimensions, excellent surface finishes, and superior corrosion resistance.

Descriptions of ANSI/ASME B16.47 SERIES B Weld Neck Flanges and Blind Flanges:

In November 1980, Subcommittee C of the American Society of Mechanical Engineers (ASME) B16 began the development of the Large Diameter Steel Flange Standard. The purpose was to establish uniform dimensions, tolerances, markings, and materials for flanges with Nominal Pipe Sizes (NPS) ranging from 26 inches to 60 inches. This standard aimed to provide consistency and compatibility in the industry.

Prior to the development of the Large Diameter Steel Flange Standard, in July 1952, the Manufacturers Standardization Society (MSS) released MSS-SP44. MSS-SP44 covered flanges for NPS 12 inches to 60 inches with pressure ratings ranging from 150# to 900#. It included various facing configurations such as raised face (RF), flat face (FF), and ring type joint (RTJ).

The initial draft of the Large Diameter Steel Flange Standard was formulated in December 1982. It underwent several revisions and modifications to ensure accuracy and effectiveness. Finally, in 1990, the standard was approved and published. The final version of the standard duplicated the specifications outlined in MSS-SP44 and replaced the API-605 specification.

The Large Diameter Steel Flange Standard consists of two series: Series A and Series B. Both series focus exclusively on weld neck and blind flange specifications. These flanges are available in different materials, including carbon steel, stainless steel, and other alloy materials. The standard aims to provide a comprehensive set of guidelines for large diameter steel flanges, ensuring consistency, reliability, and safety in various industrial applications.

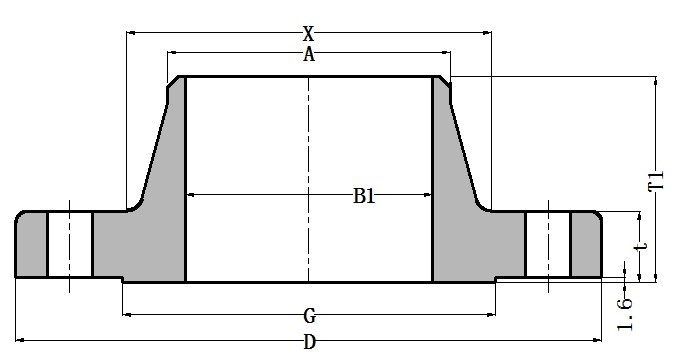

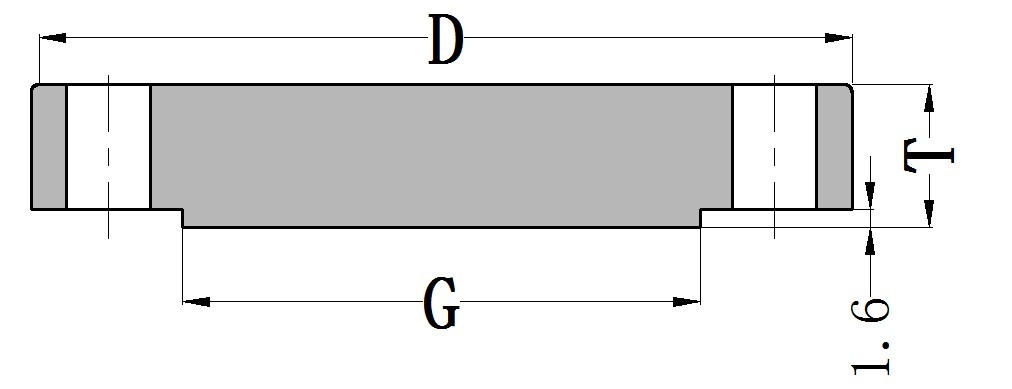

ANSI B16.47 SERIES B Weld Neck Flanges and Blind Flanges Dimensions:

| ANSI/ASME B16.47 SERIES B CLASS 75 | |||||||||||||

| Nominal Pipe size | Outside Diameter | O.D.of Raised Face | Diameter at base of Hub | Thickness | Bore | Length | Dia of Hub Top | Drilling | Weight (lb) | ||||

| D | G | X | t/T | B1 | T1 | A | Bolt Circle Dia | Number of holes | Dia of holes | Weld Neck | Blind | ||

| 26 | 762.0 | 704.9 | 676.1 | 31.8 | 31.8 | 57.2 | 661.9 | 723.9 | 36 | 19.1 | 80 | 255 | |

| 28 | 812.8 | 755.7 | 726.9 | 31.8 | 31.8 | 60.5 | 712.7 | 774.7 | 40 | 19.1 | 85 | 290 | |

| 30 | 863.6 | 806.5 | 777.7 | 31.8 | 31.8 | 63.5 | 763.5 | 825.5 | 44 | 19.1 | 90 | 330 | |

| 32 | 914.4 | 857.3 | 828.5 | 33.5 | 35.1 | 68.3 | 814.3 | 876.3 | 48 | 19.1 | 105 | 390 | |

| 34 | 965.2 | 908.1 | 879.3 | 33.5 | 36.6 | 71.6 | 865.1 | 927.1 | 52 | 19.1 | 110 | 430 | |

| 36 | 1033.5 | 965.2 | 935.0 | 35.1 | 40.9 | 84.3 | 915.9 | 992.1 | 40 | 22.4 | 145 | 518 | |

| 38 | 1084.3 | 1016.0 | 985.8 | 36.6 | 42.9 | 87.4 | 966.7 | 1042.9 | 40 | 22.4 | 160 | 595 | |

| 40 | 1135.1 | 1066.8 | 1036.6 | 36.6 | 42.9 | 90.7 | 1017.5 | 1093.7 | 44 | 22.4 | 170 | 760 | |

| 42 | 1185.9 | 1117.6 | 1087.4 | 38.1 | 46.2 | 93.7 | 1068.3 | 1144.5 | 48 | 22.4 | 185 | 895 | |

| 44 | 1251.0 | 1174.8 | 1140.0 | 41.4 | 47.8 | 103.4 | 1119.1 | 1203.5 | 36 | 25.4 | 230 | 1065 | |

| 46 | 1301.8 | 1225.6 | 1190.8 | 42.9 | 49.3 | 106.4 | 1169.9 | 1254.3 | 40 | 25.4 | 245 | 1185 | |

| 48 | 1352.6 | 1276.4 | 1241.6 | 44.5 | 52.6 | 109.7 | 1220.7 | 1305.1 | 44 | 25.4 | 270 | 1315 | |

| 50 | 1403.4 | 1327.2 | 1293.9 | 46.2 | 54.1 | 114.3 | 1271.5 | 1355.9 | 44 | 25.4 | 290 | 1505 | |

| 52 | 1457.5 | 1378.0 | 1344.7 | 46.2 | 55.6 | 119.1 | 1322.3 | 1409.7 | 48 | 25.4 | 310 | 1665 | |

| 54 | 1508.3 | 1428.8 | 1397.0 | 47.8 | 58.9 | 124.0 | 1373.1 | 1460.5 | 48 | 25.4 | 340 | 1840 | |

| 56 | 1574.8 | 1485.9 | 1450.8 | 49.3 | 60.5 | 133.4 | 1423.9 | 1521.0 | 40 | 28.4 | 400 | 2110 | |

| 58 | 1625.6 | 1536.7 | 1501.6 | 50.8 | 62.0 | 136.7 | 1474.7 | 1571.8 | 44 | 28.4 | 430 | 2300 | |

| 60 | 1676.4 | 1587.5 | 1552.4 | 54.1 | 65.3 | 143.0 | 1525.5 | 1622.6 | 44 | 28.4 | 475 | 2500 | |

1.Dimensions are in millimeters(mm).

2.B1 can be specified by different purchasers.

Features of ASME B16.47 Series B Carbon Steel Weld Neck Flanges and Blind Flanges:

ASME B16.47 is a standard for large diameter steel pipe flanges, which is further divided into two series: Series A and Series B. The standard covers blind flanges and weld neck flanges. Series B flanges were previously referred to as API 605 flanges.

ASME B16.47 specifies the dimensions and ratings for flanges sized from NPS 26 (Nominal Pipe Size) through NPS 60. The standard provides both metric and inch units for dimensions and ratings.

The ASME B16.47 standard incorporates two other standards: MSS SP-44 (Steel Pipeline Flanges) and API 605 (Large Diameter Carbon Steel Flanges). As a result, MSS SP-44 flanges are designated as ASME B16.47 Series A flanges, while API 605 flanges are designated as ASME B16.47 Series B flanges within this standard.

ANSI B16.47 Series B flanges are large diameter steel flanges designed and manufactured according to the specifications outlined in the ANSI B16.47 standard:

Design and Construction: ASME B16.47 Series B flanges, including weld neck flanges and blind flanges, are designed and constructed to meet the requirements of large diameter piping systems. They are manufactured with carbon steel, which provides strength, durability, and resistance to corrosion.

Long Tapered Hub: Weld neck flanges have a long tapered hub that provides reinforcement to the connection between the flange and the pipe. This design ensures better structural integrity and reduces the risk of leakage.

Raised Face (RF) or Flat Face (FF): Weld neck flanges in Series B can have a raised face or flat face configuration, allowing for effective sealing with gaskets.

Solid Plate Design: Blind flanges in Series B feature a solid plate design without any opening or bore. They are used to close off the end of a pipe or vessel, providing a secure barrier.

Raised Face (RF) or Flat Face (FF): Blind flanges can also have a raised face or flat face configuration, depending on the sealing requirements of the application.

Size Range: ASME B16.47 Series B flanges are specifically designed for large diameter piping systems. They are available in sizes ranging from 26 inches to 60 inches, accommodating the requirements of such systems.

Pressure Ratings: These flanges are designed to withstand different pressure ratings, which may vary depending on the specific application and customer requirements. The pressure ratings typically range from 75 to 900 pounds per square inch (psi).

Compatible with Various Flange Facing Configurations: ASME B16.47 Series B flanges are compatible with different flange facing configurations, including raised face (RF), flat face (FF), and ring type joint (RTJ). This provides flexibility in terms of gasket selection and sealing options.

Grades of Carbon Steel Flanges:

American standard carbon steel flanges are flanges made of carbon steel and are widely used in industries such as petroleum, chemical, natural gas, shipbuilding, construction, and water conservancy. Its carbon steel grades are usually divided into the following parts:

1.Q235: Q235 is a commonly used carbon structural steel grade specified in the Chinese national standard GB/T 700. It is often used in general engineering structures and manufacturing industries. In carbon steel flanges, Q235 material is commonly used for pipeline systems operating at low pressure, low temperature, and non-critical stress environments.

2.A105: A105 is a carbon steel material specified in the American ASTM standard, complying with ASTM A105/A105M requirements. A105 material has good weldability and mechanical properties, making it suitable for use in a wide temperature range from low to high temperatures. It is commonly used for pipeline systems and valve connections under high temperature and high-pressure conditions.

3.A350 LF2: A350 LF2 is also a carbon steel material specified in the ASTM standard, complying with ASTM A350/A350M requirements. LF2 indicates low-temperature service, and this material has good low-temperature toughness and crack resistance. It is commonly used for pipeline systems and valve connections under low-temperature conditions.

4.A694 F42/F52/F60/F65/F70: These material grades are specified in the ASTM A694 standard for carbon steel materials used in high-strength, low-temperature, or normal temperature high-pressure pipeline systems and valve connections. Different grades of materials have different strengths and corrosion resistance properties, suitable for various working conditions.

5.ASTM A181 Gr.1/Gr.2: These carbon steel flange material grades are suitable for pressure vessels, valves, and pipeline fittings under low pressure and low temperature conditions. They have good machinability and mechanical performance.

6.ASTM A516 Gr.70: Gr.70 is a commonly used medium carbon steel grade, known for its good weldability and machinability, suitable for manufacturing flanges and pipe fittings, among others.

7.A216 WCB: A216 WCB is a carbon steel casting material specified in the American ASTM standard, complying with ASTM A216/A216M requirements. WCB stands for cast carbon steel, and it is commonly used for carbon steel flanges that require casting in general engineering structures and manufacturing industries.

These material grades mentioned above are only a part of the commonly used ones, and there are other material grades in practical applications. When selecting the material grade for carbon steel flanges, it is necessary to consider engineering requirements, temperature, pressure, medium, and the requirements of relevant standards to ensure that the flange material meets the corresponding performance and safety requirements.

Applications of ASME B16.47 Series B Carbon Steel Weld Neck Flanges and Blind Flanges:

ASME B16.47 Carbon Steel Weld Neck Flanges and Blind Flanges, whether in Series A or Series B, have several applications across various industries.

Oil and Gas Industry: Weld Neck Flanges and Blind Flanges are extensively used in the oil and gas industry for pipeline connections, storage tanks, and refineries. They provide a secure and leak-proof connection for high-pressure and high-temperature applications.

Petrochemical Industry: ASME B16.47 Carbon Steel Flanges are widely employed in petrochemical plants for connecting pipes, valves, and equipment. They ensure reliable and durable connections in processing units, such as distillation columns, reactors, and heat exchangers.

Power Generation: Weld Neck and Blind Flanges are utilized in power plants, including thermal power plants, nuclear power plants, and renewable energy facilities. They are used in pipeline systems, steam turbines, boilers, and other equipment, providing robust connections in demanding operating conditions.

Chemical Industry: Carbon Steel Flanges find applications in the chemical industry for handling corrosive fluids and chemicals. They are used in chemical processing plants, storage tanks, and transportation systems, ensuring the safe and efficient flow of various substances.

Water and Wastewater Treatment: ASME B16.47 Flanges are employed in water treatment facilities, wastewater treatment plants, and desalination plants. They are used for connecting pipes, valves, and pumps, providing secure and leak-free connections in water distribution and treatment systems.

Mining and Minerals: Carbon Steel Flanges are utilized in mining operations for transporting minerals, ores, and slurries. They are employed in pipelines, crushers, conveyors, and other equipment, enabling efficient material handling and processing.

Construction and Infrastructure: Weld Neck and Blind Flanges are used in construction projects and infrastructure development, including buildings, bridges, and pipelines. They ensure reliable connections in plumbing systems, HVAC systems, and water supply networks.

Carbon steel weld neck flanges are pipeline connection components widely used in various industries. They play important roles in the petroleum and gas industry, chemical industry, power plants, and manufacturing industry, providing reliable pipeline connection solutions.