Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

ASME B16.9 Carbon Steel ASTM A234 WPB Reducing Tee Pipe Fittings Unequal Tees for Various Industries and Applications

Product Introduction:

ASME B16.9 Carbon Steel Reducing Tees are pipe fittings used to combine or divide fluids or gases flowing through pipes with different diameters. These tees have three openings, with two outlets that are of different sizes and branch off at a 90-degree angle from the mainline.

ASME B16.9 Carbon Steel Reducing Tees are designed to connect pipes with different diameters, allowing for a smooth transition in the flow of fluids or gases. The larger outlet of the tee is typically connected to the mainline, while the two smaller outlets are connected to the pipes of smaller diameter.

These fittings are commonly used in piping systems where there is a need to merge or split flows between different pipe sizes. They provide a convenient and efficient solution for accommodating variations in pipe diameters and maintaining the desired flow characteristics.

These Reducing Tees are manufactured in accordance with the B16.9 standard, which specifies the dimensions, materials, and other requirements for pipe fittings. This ensures that the tees meet industry standards and can be reliably used in various piping applications.

Features of ASME B16.9 Carbon Steel Unequal Tees/Reducing Tees:

Flexibility in Design: ASME B16.9 Carbon Steel Unequal Tees allow for the connection of three pipes of varying diameters at a 90-degree angle. This offers flexibility in system design, allowing for the branching or merging of flows between pipes with different sizes. It enables the creation of complex piping configurations to suit specific requirements.

Efficient Flow Distribution: ASME B16.9 Carbon Steel Unequal Tees provide efficient flow distribution by accommodating pipes of different diameters. They help to reduce pressure drop and turbulence in the system, ensuring smooth and uniform flow. This leads to improved system performance and reduced energy consumption.

Versatility in Application: ASME B16.9 Carbon Steel Unequal Tees can be used in a wide range of applications where the combination or division of fluids or gases is required. They find utility in industries such as oil and gas, petrochemical, water treatment, HVAC, and many others.

Easy Installation: ASME B16.9 Carbon Steel Unequal Tees are designed for easy installation and connection to pipes using standard methods such as welding, threading, or flanging. They are readily available in the market and can be integrated into piping systems with minimal effort.

High-Quality Standards: ASME B16.9 Carbon Steel Unequal Tees are manufactured in compliance with the B16.9 standard, ensuring dimensional accuracy, material quality, and overall performance. This guarantees that the tees meet industry standards and can be relied upon for their durability and long service life.

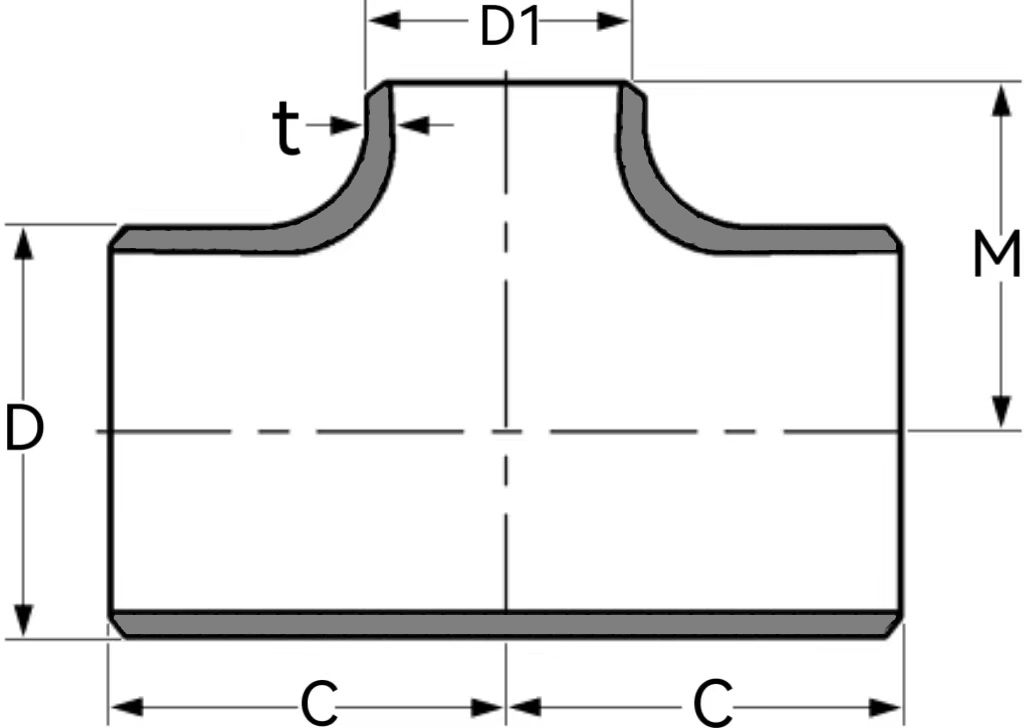

ASME B16.9 Carbon Steel Reducing Tees Dimensions:

| ASME B16.9 Reducing Tee Dimensions | ||||

| NPS | D(outer dimension) | D1(outer dimension) | C(Center-to-End) | M(Center-to-End) |

| 1/2 x 1/2 x 3/8 | 21.3 | 17.3 | 25 | 25 |

| 1/2 x 1/2 x 1/4 | 21.3 | 13.7 | 25 | 25 |

| 3/4 x 3/4 x 1/2 | 26.7 | 21.3 | 29 | 29 |

| 3/4 x 3/4 x 3/8 | 26.7 | 17.3 | 29 | 29 |

| 1 x 1 x 3/4 | 33.4 | 26.7 | 38 | 38 |

| 1 x 1 x 1/2 | 33.4 | 21.3 | 38 | 38 |

| 1-1/4 x 1-1/4 x 1 | 42.2 | 33.4 | 48 | 48 |

| 1-1/4 x 1-1/4 x 3/4 | 42.2 | 26.7 | 48 | 48 |

| 1-1/4 x 1-1/4 x 1/2 | 42.2 | 21.3 | 48 | 48 |

| 1-1/2 x 1-1/2 x 1-1/4 | 48.3 | 42.2 | 57 | 57 |

| 1-1/2 x 1-1/2 x 1 | 48.3 | 33.4 | 57 | 57 |

| 1-1/2 x 1-1/2 x 3/4 | 48.3 | 26.7 | 57 | 57 |

| 1-1/2 x 1-1/2 x 1/2 | 48.3 | 21.3 | 57 | 57 |

| 2 x 2 x 1-1/2 | 60.3 | 48.3 | 64 | 60 |

| 2 x 2 x 1-1/4 | 60.3 | 42.2 | 64 | 57 |

| 2 x 2 x 1 | 60.3 | 33.4 | 64 | 51 |

| 2 x 2 x 3/4 | 60.3 | 26.7 | 64 | 44 |

| 2-1/2 x 2-1/2 x 2 | 73 | 60.3 | 76 | 70 |

| 2-1/2 x 2-1/2 x 1-1/2 | 73 | 48.3 | 76 | 67 |

| 2-1/2 x 2-1/2 x 1-1/4 | 73 | 42.2 | 76 | 64 |

| 2-1/2 x 2-1/2 x 1 | 73 | 33.4 | 76 | 57 |

| 3 x 3 x 2-1/2 | 88.9 | 73 | 86 | 83 |

| 3 x 3 x 2 | 88.9 | 60.3 | 86 | 76 |

| 3 x 3 x 1-1/2 | 88.9 | 48.3 | 86 | 73 |

| 3 x 3 x 1-1/4 | 88.9 | 42.2 | 86 | 70 |

| 3-1/2 x 3-1/2 x 3 | 101.6 | 88.9 | 95 | 92 |

| 3-1/2 x 3-1/2 x 2-1/2 | 101.6 | 73 | 95 | 89 |

| 3-1/2 x 3-1/2 x 2 | 101.6 | 60.3 | 95 | 83 |

| 3-1/2 x 3-1/2 x 1-1/2 | 101.6 | 48.3 | 95 | 79 |

| 4 x 4 x 3-1/2 | 114.3 | 101.6 | 105 | 102 |

| 4 x 4 x 3 | 114.3 | 88.9 | 105 | 98 |

| 4 x 4 x 2-1/2 | 114.3 | 73 | 105 | 95 |

| 4 x 4 x 2 | 114.3 | 60.3 | 105 | 89 |

| 4 x 4 x 1-1/2 | 114.3 | 48.3 | 105 | 86 |

| 5 x 5 x 4 | 141.3 | 114.3 | 124 | 117 |

| 5 x 5 x 3-1/2 | 141.3 | 101.6 | 124 | 114 |

| 5 x 5 x 3 | 141.3 | 88.9 | 124 | 111 |

| 5 x 5 x 2-1/2 | 141.3 | 73 | 124 | 108 |

| 5 x 5 x 2 | 141.3 | 60.3 | 124 | 105 |

| 6 x 6 x 5 | 168.3 | 141.3 | 143 | 137 |

| 6 x 6 x 4 | 168.3 | 114.3 | 143 | 130 |

| 6 x 6 x 3-1/2 | 168.3 | 101.6 | 143 | 127 |

| 6 x 6 x 3 | 168.3 | 88.9 | 143 | 124 |

| 6 x 6 x 2-1/2 | 168.3 | 73 | 143 | 121 |

| 8 x 8 x 6 | 219.1 | 168.3 | 178 | 168 |

| 8 x 8 x 5 | 219.1 | 141.3 | 178 | 162 |

| 8 x 8 x 4 | 219.1 | 114.3 | 178 | 156 |

| 8 x 8 x 3-1/2 | 219.1 | 101.6 | 178 | 152 |

| 10 x 10 x 8 | 273 | 219.1 | 216 | 203 |

| 10 x 10 x 6 | 273 | 168.3 | 216 | 194 |

| 10 x 10 x 5 | 273 | 141.3 | 216 | 191 |

| 10 x 10 x 4 | 273 | 114.3 | 216 | 184 |

| 12 x 12 x 10 | 323.8 | 273 | 254 | 241 |

| 12 x 12 x 8 | 323.8 | 219.1 | 254 | 229 |

| 12 x 12 x 6 | 323.8 | 168.3 | 254 | 219 |

| 12 x 12 x 5 | 323.8 | 141.3 | 254 | 216 |

| 14 x 14 x 12 | 355.6 | 323.8 | 279 | 270 |

| 14 x 14 x 10 | 355.6 | 273 | 279 | 257 |

| 14 x 14 x 8 | 355.6 | 219.1 | 279 | 248 |

| 14 x 14 x 6 | 355.6 | 168.3 | 279 | 238 |

| 16 x 16 x 14 | 406.4 | 355.6 | 305 | 305 |

| 16 x 16 x 12 | 406.4 | 323.8 | 305 | 295 |

| 16 x 16 x 10 | 406.4 | 273 | 305 | 283 |

| 16 x 16 x 8 | 406.4 | 219.1 | 305 | 273 |

| 16 x 16 x 6 | 406.4 | 168.3 | 305 | 264 |

| 18 x 18 x 16 | 457 | 406.4 | 343 | 330 |

| 18 x 18 x 14 | 457 | 355.6 | 343 | 330 |

| 18 x 18 x 12 | 457 | 323.8 | 343 | 321 |

| 18 x 18 x 10 | 457 | 273 | 343 | 308 |

| 18 x 18 x 8 | 457 | 219.1 | 343 | 298 |

| 20 x 20 x 18 | 508 | 457 | 381 | 368 |

| 20 x 20 x 16 | 508 | 406.4 | 381 | 356 |

| 20 x 20 x 14 | 508 | 355.6 | 381 | 356 |

| 20 x 20 x 12 | 508 | 323.8 | 381 | 346 |

| 20 x 20 x 10 | 508 | 273 | 381 | 333 |

| 20 x 20 x 8 | 508 | 219.1 | 381 | 324 |

| 22 x 22 x 20 | 559 | 508 | 419 | 406 |

| 22 x 22 x 18 | 559 | 457 | 419 | 394 |

| 22 x 22 x 16 | 559 | 406.4 | 419 | 381 |

| 22 x 22 x 14 | 559 | 355.6 | 419 | 381 |

| 22 x 22 x 12 | 559 | 323.8 | 419 | 371 |

| 22 x 22 x 10 | 559 | 273 | 419 | 359 |

| 24 x 24 x 22 | 610 | 559 | 432 | 432 |

| 24 x 24 x 20 | 610 | 508 | 432 | 432 |

| 24 x 24 x 18 | 610 | 457 | 432 | 419 |

| 24 x 24 x 16 | 610 | 406.4 | 432 | 406 |

| 24 x 24 x 14 | 610 | 355.6 | 432 | 406 |

| 24 x 24 x 12 | 610 | 323.8 | 432 | 397 |

| 24 x 24 x 10 | 610 | 273 | 432 | 384 |

| 26 x 26 x 24 | 660 | 610 | 495 | 483 |

| 26 x 26 x 22 | 660 | 559 | 495 | 470 |

| 26 x 26 x 20 | 660 | 508 | 495 | 457 |

| 26 x 26 x 18 | 660 | 457 | 495 | 444 |

| 26 x 26 x 16 | 660 | 406.4 | 495 | 432 |

| 26 x 26 x 14 | 660 | 355.6 | 495 | 432 |

| 26 x 26 x 12 | 660 | 323.8 | 495 | 422 |

| 28 x 28 x 26 | 711 | 660 | 521 | 521 |

| 28 x 28 x 24 | 711 | 610 | 521 | 508 |

| 28 x 28 x 22 | 711 | 559 | 521 | 495 |

| 28 x 28 x 20 | 711 | 508 | 521 | 483 |

| 28 x 28 x 18 | 711 | 457 | 521 | 470 |

| 28 x 28 x 16 | 711 | 406.4 | 521 | 457 |

| 28 x 28 x 14 | 711 | 355.6 | 521 | 457 |

| 28 x 28 x 12 | 711 | 323.8 | 521 | 448 |

| 30 x 30 x 28 | 762 | 711 | 559 | 546 |

| 30 x 30 x 26 | 762 | 660 | 559 | 546 |

| 30 x 30 x 24 | 762 | 610 | 559 | 533 |

| 30 x 30 x 22 | 762 | 559 | 559 | 521 |

| 30 x 30 x 20 | 762 | 508 | 559 | 508 |

| 30 x 30 x 18 | 762 | 457 | 559 | 495 |

| 30 x 30 x 16 | 762 | 406.4 | 559 | 483 |

| 30 x 30 x 14 | 762 | 355.6 | 559 | 483 |

| 30 x 30 x 12 | 762 | 323.8 | 559 | 473 |

| 30 x 30 x 10 | 762 | 273 | 559 | 460 |

| 32 x 32 x 30 | 813 | 762 | 597 | 584 |

| 32 x 32 x 28 | 813 | 711 | 597 | 572 |

| 32 x 32 x 26 | 813 | 660 | 597 | 572 |

| 32 x 32 x 24 | 813 | 610 | 597 | 559 |

| 32 x 32 x 22 | 813 | 559 | 597 | 546 |

| 32 x 32 x 20 | 813 | 508 | 597 | 533 |

| 32 x 32 x 18 | 813 | 457 | 597 | 521 |

| 32 x 32 x 16 | 813 | 406.4 | 597 | 508 |

| 32 x 32 x 14 | 813 | 355.6 | 597 | 508 |

| 34 x 34 x 32 | 864 | 813 | 635 | 622 |

| 34 x 34 x 30 | 864 | 762 | 635 | 610 |

| 34 x 34 x 28 | 864 | 711 | 635 | 597 |

| 34 x 34 x 26 | 864 | 660 | 635 | 597 |

| 34 x 34 x 24 | 864 | 610 | 635 | 584 |

| 34 x 34 x 22 | 864 | 559 | 635 | 572 |

| 34 x 34 x 20 | 864 | 508 | 635 | 559 |

| 34 x 34 x 18 | 864 | 457 | 635 | 546 |

| 34 x 34 x 16 | 864 | 406.4 | 635 | 533 |

| 36 x 36 x 34 | 914 | 864 | 673 | 660 |

| 36 x 36 x 32 | 914 | 813 | 673 | 648 |

| 36 x 36 x 30 | 914 | 762 | 673 | 635 |

| 36 x 36 x 28 | 914 | 711 | 673 | 622 |

| 36 x 36 x 26 | 914 | 660 | 673 | 622 |

| 36 x 36 x 24 | 914 | 610 | 673 | 610 |

| 36 x 36 x 22 | 914 | 559 | 673 | 597 |

| 36 x 36 x 20 | 914 | 508 | 673 | 584 |

| 36 x 36 x 18 | 914 | 457 | 673 | 572 |

| 36 x 36 x 16 | 914 | 406.4 | 673 | 559 |

| 38 x 38 x 36 | 965 | 914 | 711 | 711 |

| 38 x 38 x 34 | 965 | 864 | 711 | 698 |

| 38 x 38 x 32 | 965 | 813 | 711 | 686 |

| 38 x 38 x 30 | 965 | 762 | 711 | 673 |

| 38 x 38 x 28 | 965 | 711 | 711 | 648 |

| 38 x 38 x 26 | 965 | 660 | 711 | 648 |

| 38 x 38 x 24 | 965 | 610 | 711 | 635 |

| 38 x 38 x 22 | 965 | 559 | 711 | 622 |

| 38 x 38 x 20 | 965 | 508 | 711 | 610 |

| 38 x 38 x 18 | 965 | 457 | 711 | 597 |

| 40 x 40 x 38 | 1016 | 965 | 749 | 749 |

| 40 x 40 x 36 | 1016 | 914 | 749 | 737 |

| 40 x 40 x 34 | 1016 | 864 | 749 | 724 |

| 40 x 40 x 32 | 1016 | 813 | 749 | 711 |

| 40 x 40 x 30 | 1016 | 762 | 749 | 698 |

| 40 x 40 x 28 | 1016 | 711 | 749 | 673 |

| 40 x 40 x 26 | 1016 | 660 | 749 | 673 |

| 40 x 40 x 24 | 1016 | 610 | 749 | 660 |

| 40 x 40 x 22 | 1016 | 559 | 749 | 648 |

| 40 x 40 x 20 | 1016 | 508 | 749 | 635 |

| 40 x 40 x 18 | 1016 | 457 | 749 | 622 |

| 42 x 42 x 40 | 1067 | 1016 | 762 | 711 |

| 42 x 42 x 38 | 1067 | 965 | 762 | 711 |

| 42 x 42 x 36 | 1067 | 914 | 762 | 711 |

| 42 x 42 x 34 | 1067 | 864 | 762 | 711 |

| 42 x 42 x 32 | 1067 | 813 | 762 | 711 |

| 42 x 42 x 30 | 1067 | 762 | 762 | 711 |

| 42 x 42 x 28 | 1067 | 711 | 762 | 698 |

| 42 x 42 x 26 | 1067 | 660 | 762 | 698 |

| 42 x 42 x 24 | 1067 | 610 | 762 | 660 |

| 42 x 42 x 22 | 1067 | 559 | 762 | 660 |

| 42 x 42 x 20 | 1067 | 508 | 762 | 660 |

| 42 x 42 x 18 | 1067 | 457 | 762 | 648 |

| 42 x 42 x 16 | 1067 | 406.4 | 762 | 635 |

| 44 x 44 x 42 | 1118 | 1067 | 813 | 762 |

| 44 x 44 x 40 | 1118 | 1016 | 813 | 749 |

| 44 x 44 x 38 | 1118 | 965 | 813 | 737 |

| 44 x 44 x 36 | 1118 | 914 | 813 | 724 |

| 44 x 44 x 34 | 1118 | 864 | 813 | 724 |

| 44 x 44 x 32 | 1118 | 813 | 813 | 711 |

| 44 x 44 x 30 | 1118 | 762 | 813 | 711 |

| 44 x 44 x 28 | 1118 | 711 | 813 | 698 |

| 44 x 44 x 26 | 1118 | 660 | 813 | 698 |

| 44 x 44 x 24 | 1118 | 610 | 813 | 698 |

| 44 x 44 x 22 | 1118 | 559 | 813 | 686 |

| 44 x 44 x 20 | 1118 | 508 | 813 | 686 |

| 46 x 46 x 44 | 1168 | 1118 | 851 | 800 |

| 46 x 46 x 42 | 1168 | 1067 | 851 | 787 |

| 46 x 46 x 40 | 1168 | 1016 | 851 | 775 |

| 46 x 46 x 38 | 1168 | 965 | 851 | 762 |

| 46 x 46 x 36 | 1168 | 914 | 851 | 762 |

| 46 x 46 x 34 | 1168 | 864 | 851 | 749 |

| 46 x 46 x 32 | 1168 | 813 | 851 | 749 |

| 46 x 46 x 30 | 1168 | 762 | 851 | 737 |

| 46 x 46 x 28 | 1168 | 711 | 851 | 737 |

| 46 x 46 x 26 | 1168 | 660 | 851 | 737 |

| 46 x 46 x 24 | 1168 | 610 | 851 | 724 |

| 46 x 46 x 22 | 1168 | 559 | 851 | 724 |

| 48 x 48 x 46 | 1219 | 1168 | 889 | 838 |

| 48 x 48 x 44 | 1219 | 1118 | 889 | 838 |

| 48 x 48 x 42 | 1219 | 1067 | 889 | 813 |

| 48 x 48 x 40 | 1219 | 1016 | 889 | 813 |

| 48 x 48 x 38 | 1219 | 965 | 889 | 813 |

| 48 x 48 x 36 | 1219 | 914 | 889 | 787 |

| 48 x 48 x 34 | 1219 | 864 | 889 | 787 |

| 48 x 48 x 32 | 1219 | 813 | 889 | 787 |

| 48 x 48 x 30 | 1219 | 762 | 889 | 762 |

| 48 x 48 x 28 | 1219 | 711 | 889 | 762 |

| 48 x 48 x 26 | 1219 | 660 | 889 | 762 |

| 48 x 48 x 24 | 1219 | 610 | 889 | 737 |

| 48 x 48 x 22 | 1219 | 559 | 889 | 737 |

Description of ASTM A234 WPB Reducing Tees:

ASTM A234 WPB is a widely used standard specification for forged or wrought carbon steel pipe fittings designed for moderate and high-temperature services. These fittings are essential components in the construction of pressure pipelines and vessels that operate under varying temperature conditions. The WPB designation specifically refers to the grade of carbon steel material used, with WPB being the most commonly utilized grade for applications requiring resistance to moderate to high temperatures. The fittings covered under this specification include tees, reducers (concentric and eccentric), bends (5D/6D), elbows, caps, crosses, bridge plugs, headers, and more. These fittings are typically manufactured using materials like ASTM A106 Gr.C steel pipes or ASTM A285 Gr.C steel plates.

Advantages of ASTM A234 WPB:

Strength and Durability: Carbon Steel A234 WPB exhibits good strength and durability, making it suitable for various applications. It can withstand high pressures and temperatures, making it commonly used in industries such as oil and gas, chemical processing, power generation, and more.

Weldability: ASTM A234 WPB is known for its excellent weldability. It can be easily welded using common welding methods, such as butt welding, which involves joining the fittings by heating the ends and applying pressure to create a strong and leak-free connection.

Affordability: Carbon Steel A234 WPB is a cost-effective choice for pipe fittings. It offers a balance between performance and affordability, making it a popular option for a wide range of applications.

Size Range and Fitting Types: ASTM A234 WPB fittings are available in various sizes and types to accommodate different piping requirements. Common types of fittings include elbows, tees, reducers, caps, and stub ends. These fittings are used to connect and redirect the flow of fluids or gases in a piping system.

Applications of ASME B16.9 Carbon Steel Reducing Tees:

Size Transition: ASME B16.9 Carbon Steel Reducing Tees allow for a smooth transition between pipes of different diameters. They provide a convenient and efficient solution for connecting pipes with varying sizes, ensuring proper flow and minimizing pressure drop.

Branching or Diverting Flow: ASME B16.9 Carbon Steel Reducing Tees enable the branching or diverting of flow in a piping system. They allow for the distribution of fluids or gases to multiple lines or equipment, accommodating different flow requirements.

System Design Flexibility: By using ASME B16.9 Carbon Steel Reducing Tees, designers have more flexibility in designing piping systems. They can easily accommodate changes in pipe size or adapt to specific space constraints, optimizing the layout and functionality of the system.