Shaanxi Peter International Trade Co., Ltd. |

|

Verified Suppliers

|

|

BS4504 CODE 113 PN6 Carbon Steel and Stainless Steel Threaded Flanges Raised Face (THRF)

Introduction:

Our company, Shaanxi Peter International Trade Co., Ltd. is a highly reputable and well-established supplier in the market, boasting an impressive track record of over two decades. With our extensive experience and expertise, we have garnered a strong reputation as a trusted and reliable source for BS4504 Carbon Steel and Stainless Steel Threaded Flanges. Our commitment to quality and customer satisfaction has made us a preferred choice for customers seeking top-notch threaded flange solutions.

Over the years, we have built solid relationships with renowned manufacturers and have access to a comprehensive range of BS4504 Carbon Steel Threaded Flanges and Stainless Steel Threaded Flanges. Our inventory comprises flanges crafted from high-quality stainless steel, ensuring exceptional durability, corrosion resistance, and longevity. We understand the criticality of precision and adherence to industry standards, which is why we source flanges that conform to the stringent specifications of the BS4504 standard.

Description of BS4504 Carbon Steel and Stainless Steel Threaded Flanges:

A threaded flange is a type of flange designed with internal threads, allowing it to be connected to a threaded pipe without the need for welding. It offers the convenience of easy installation and maintenance, making it a suitable option in situations where welding is impractical or not possible.

In cases where alloy steel flanges have sufficient strength but pose challenges in welding or have poor welding performance, threaded flanges serve as a viable alternative. However, it's important to consider the limitations of threaded flanges. They should not be used in applications involving sharp temperature changes or where the temperature exceeds 260°C or falls below -45°C, as this can lead to potential leakage issues.

Threaded flanges have a similar appearance to Slip-On flanges, but they are specifically bored to match the inner diameter of the pipe. The backside of the center opening is then threaded with tapered pipe threads of the appropriate size.

The primary advantage of threaded flanges is the absence of welding requirements, resulting in minimal additional torque applied to the pipe or barrel during flange deformation. However, threaded flanges tend to be thicker and more expensive compared to other flange types. They are particularly well-suited for high-pressure pipe connections.

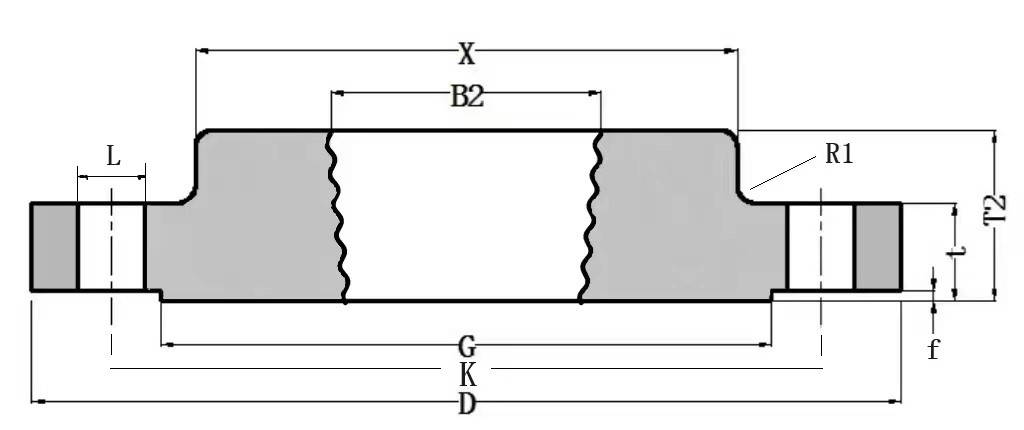

BS4504 Carbon Steel and Stainless Steel Threaded Flange Dimensions:

| BS4504 CODE 113 THREADED FLANGES PN 6 THRF | |||||||||||

| DN | Outside Diameter | O.D.of Raised Face |

Height of Raised Face | Neck Diameter | Thickness | Dia Counter Bore | Length of Flange | Bolt circle diameter | Number of holes | Diameter of Bolt |

Radius of Corners

|

| D | G | f | X | t | B2 | T2 | K | Numbers | L | R1 | |

| 10 | 75 | 35 | 2 | 25 | 12 | 18.0 | 20 | 50 | 4 | 11 | 3 |

| 15 | 80 | 40 | 2 | 30 | 12 | 22.0 | 20 | 55 | 4 | 11 | 3 |

| 20 | 90 | 50 | 2 | 40 | 14 | 27.5 | 24 | 65 | 4 | 11 | 4 |

| 25 | 100 | 60 | 2 | 50 | 14 | 34.5 | 24 | 75 | 4 | 11 | 4 |

| 32 | 120 | 70 | 2 | 60 | 14 | 43.5 | 26 | 90 | 4 | 14 | 5 |

| 40 | 130 | 80 | 3 | 70 | 14 | 49.5 | 26 | 100 | 4 | 14 | 5 |

| 50 | 140 | 90 | 3 | 80 | 14 | 61.5 | 28 | 110 | 4 | 14 | 5 |

| 65 | 160 | 110 | 3 | 100 | 14 | 77.5 | 32 | 130 | 4 | 14 | 6 |

| 80 | 190 | 128 | 3 | 110 | 16 | 90.5 | 34 | 150 | 4 | 18 | 6 |

| 100 | 210 | 148 | 3 | 130 | 16 | 116.0 | 40 | 170 | 4 | 18 | 6 |

| 125 | 240 | 178 | 3 | 160 | 18 | 141.5 | 44 | 200 | 8 | 18 | 6 |

| 150 | 265 | 202 | 3 | 185 | 18 | 170.5 | 44 | 225 | 8 | 18 | 8 |

| 200 | 320 | 258 | 3 | 240 | 20 | 221.5 | 44 | 280 | 8 | 18 | 8 |

| 250 | 375 | 312 | 3 | 295 | 22 | 276.5 | 44 | 335 | 12 | 18 | 10 |

| 300 | 440 | 365 | 4 | 355 | 22 | 327.5 | 44 | 395 | 12 | 22 | 10 |

| 350 | 490 | 415 | 4 | - | 22 | 359.5 | - | 445 | 12 | 22 | 10 |

| 400 | 540 | 465 | 4 | - | 22 | 411.0 | - | 495 | 16 | 22 | 10 |

| 450 | 595 | 520 | 4 | - | 24 | 462.0 | - | 550 | 16 | 22 | 12 |

| 500 | 645 | 570 | 4 | - | 24 | 513.5 | - | 600 | 20 | 22 | 12 |

| 600 | 755 | 670 | 5 | - | 24 | 616.5 | - | 705 | 20 | 26 | 12 |

| 700 | 860 | 775 | 5 | - | 24 | - | - | 810 | 24 | 26 | 12 |

| 800 | 975 | 880 | 5 | - | 24 | - | - | 920 | 24 | 30 | 12 |

| 900 | 1075 | 980 | 5 | - | 26 | - | - | 1020 | 24 | 30 | 12 |

| 1000 | 1175 | 1080 | 5 | - | 26 | - | - | 1120 | 28 | 30 | 12 |

| 1200 | 1405 | 1295 | 5 | - | 28 | - | - | 1340 | 32 | 33 | 12 |

| 1400 | 1630 | 1510 | 5 | - | 32 | - | - | 1560 | 36 | 36 | 12 |

| 1600 | 1830 | 1710 | 5 | - | 34 | - | - | 1760 | 40 | 36 | 12 |

| 1800 | 2045 | 1920 | 5 | - | 36 | - | - | 1970 | 44 | 39 | 15 |

| 2000 | 2265 | 2125 | 5 | - | 38 | - | - | 2180 | 48 | 42 | 15 |

1.Dimensions are in millimeters(mm).

2.Dimensions can be specified by different purchasers.

When Should BS4504 Threaded Flanges be used:

Cost Consideration: BS4504 Threaded flanges are generally more cost-effective compared to other types of flanges, such as welded flanges. If cost is a significant factor for your project, threaded flanges can be a suitable choice.

Frequent Disassembly: If you anticipate the need for frequent disassembly of the flange, threaded flanges offer convenience. The threaded connection allows for easy removal and reinstallation without requiring welding or specialized tools.

Low-Pressure Applications: BS4504 Threaded flanges are suitable for applications where the system operates at relatively low pressures. They can handle moderate pressure levels effectively. However, for high-pressure applications, other types of flanges, such as weld neck flanges or slip-on flanges, may be more appropriate.

Non-Critical Applications: If the application does not involve critical processes or components where leakage or failure could have severe consequences, BS4504 threaded flanges can be a viable option. They may be used in non-critical systems or applications where the consequences of a leak or failure are minimal.

Non-Vibrating Systems: BS4504 Threaded flanges may be used in systems with minimal vibration. Vibrations can potentially loosen the threaded connection over time, leading to leaks. If the system experiences significant vibration, other flange types that provide better resistance to loosening, such as weld neck flanges with a welded connection, may be more suitable.

Applications of BS4504 Carbon Steel and Stainless Steel Threaded Flanges:

BS4504 Carbon Steel and Stainless Steel Threaded Flanges find applications in various industries and piping systems. Here are some common applications where these flanges are used:

Plumbing Systems: BS4504 Carbon Steel and Stainless Steel Threaded Flanges are frequently utilized in plumbing systems, such as water supply networks, wastewater systems, and irrigation systems. They provide a secure connection between pipes, valves, and fittings, allowing for easy installation and maintenance.

Industrial Pipelines: BS4504 Carbon Steel and Stainless Steel Threaded Flanges are suitable for industrial pipelines that transport fluids or gases, including oil and gas pipelines, chemical processing plants, power plants, and refineries. Their threaded connection enables a reliable joint that can withstand moderate pressure and temperature conditions.

HVAC Systems: BS4504 Carbon Steel and Stainless Steel Threaded Flanges are employed in heating, ventilation, and air conditioning (HVAC) systems. They connect pipes, pumps, and other HVAC components, facilitating the efficient transfer of hot or cold air throughout buildings or industrial facilities.

Process Piping: In various process industries, such as food and beverage, pharmaceuticals, and petrochemicals, BS4504 Carbon Steel and Stainless Steel Threaded Flanges are used for process piping. They provide a secure and easily detachable connection for conveying liquids, gases, or powders in manufacturing and production processes.

Water Treatment Plants: BS4504 Carbon Steel and Stainless Steel Threaded Flanges are utilized in water treatment plants for connecting pipes and components in filtration systems, pumping stations, and distribution networks. They play a crucial role in ensuring the safe and efficient treatment and distribution of potable water.

General Industrial Applications: BS4504 Carbon Steel and Stainless Steel Threaded Flanges are used in a wide range of general industrial applications where a threaded connection is preferred or required. This includes equipment manufacturing, machine assembly, and various utility pipelines.