Dongguan Chuangwei Electronic Equipment Manufactory |

|

Verified Suppliers

|

|

CNC Control Program Prototype PCB Routing Machine With Double Station

Software

Control system | Windows XP Professional (Service3,v.3244) |

Operation GUI | Chinese Windows XP |

Program edit | Inline |

Vision system | CCD AOTU offset |

Control system | F 1.0.2 version |

Hardware

CCD | Sony 520 line industrial cameras |

LENS | Computar EX2C |

Screw | TBI Precision ground ball screw imports |

Guide | HIWIN widening Imported linear guide rail |

MOTOR | JiaBao LCF Series |

I/O CONTRONL CARD | HFC PCI-9074 |

DRIVER CONTRONL CARD | HFC PCI-9074 |

I/O CARD | PCI-9074-64pcs/-38pcs |

Static cleanup | STATIC-ST401A Series |

Computer | RMC-8401/6113LP4/300ATX/8651VNA/P4 2.8G 2CPU(S)/1G DDR/80G |

Machine interface | AOC LCD17",Logitech mouse |

Performance parameters

Overall | |

Dimensions(W*D*H) | 1220mm*1450mm*1420mm |

Weight | 550KG |

Height offset | 60~110mm |

Manipulator | |

Motor type | JiaBao series |

Positioning repeatability | 0.001mm |

Axis working area(max) | 680mm*360mm*50mm |

Work station | |

Work station | standard,specialization |

PCB loading/unloading | manual |

PCB size (max) | 322mm*322mm |

PCB thick (max) | 5mm |

Fixturing | |

Rigidity fixturing | standard |

Fixturing fixation | machinery |

Spindle Motor | |

Power | 400W |

Spindle | 50000rpm/min |

Protect | self/wind cooling |

Change cutter | Specialization |

Routing capability | |

Cutting speed(max.) | 100mm/s |

Driving speed(max.) | 3000mm/s |

Precision of cutting | 0.01mm |

Vacuum System | |

Vacuum power | 2.2KW AC 380V |

Vacuum plumb | |

Utilities | |

Power | 2.2KW AC380V |

Air supply | 2~5KG/cm2 |

Description

Solution for stress free depanelization

Fixture-based highly efficient dust vacuum system

Clean and precise depanelization for densely populated PCBs

Advanced image-processing software offers point-and-click operation

for programming router paths

Automatic alignment compensation by CCD camera

User-friendly operation

Extended bit life by automatic router bit depth adjustment

Improved tact time

Low maintenance required

Reasonable price

Calibration free linear robot

Depaneling with a PCB Router

Benefits of PCB Depaneling

There is no better way to depanel a printed circuit board than with the Sayaka PCB Router. This PCB depaneler is the answer for hassle-free PCB depaneling through the employment of a router bit that minimizes stress on components. The high speed spindle included in the machine speeds up cutting and maintains precision, while also allowing for flexible panel designs with various cutting patterns. Our PCB depaneler will also cut down on bit replacement with our router bit depth adjustment system, which automatically shifts up to 5 depth levels. The PCB router bit maximum cutting speed is 50mm per second, while the traveling speed is a maximum of 800mm per second. With a built-in fixture based dust vacuum system, the system is sure to be clean and efficient. This prevents warping, and takes full advantage of vacuum strength for the most effectual dust collection.

Easy Operation

Easy to operate, the image processing software of the PCB router makes it simple to program cutting paths with point-and-click technology, whereas it also automatically compensates for alignment with a CCD camera. With the simple touch of an external button PCB depaneling can be started promptly for easy operation, and through the easy to use pre-programming mode, the operation of the machinery is made even more undemanding. The PCB depaneler is also very low maintenance, as the machine is designed for easy access and repairs. Frame structure and the spindle motor operate on an X, Y and Z axis, while ceramic bearing is integrated to provide 60,000rpm for spins.

Cost Effective

With the variety of benefits that our depaneling systems offer, and the ease in which the machinery can be operated, the price is undeniably practical. Not only are depaneling needs taken care of with efficiency and simplicity, but the low cost will save money and time.

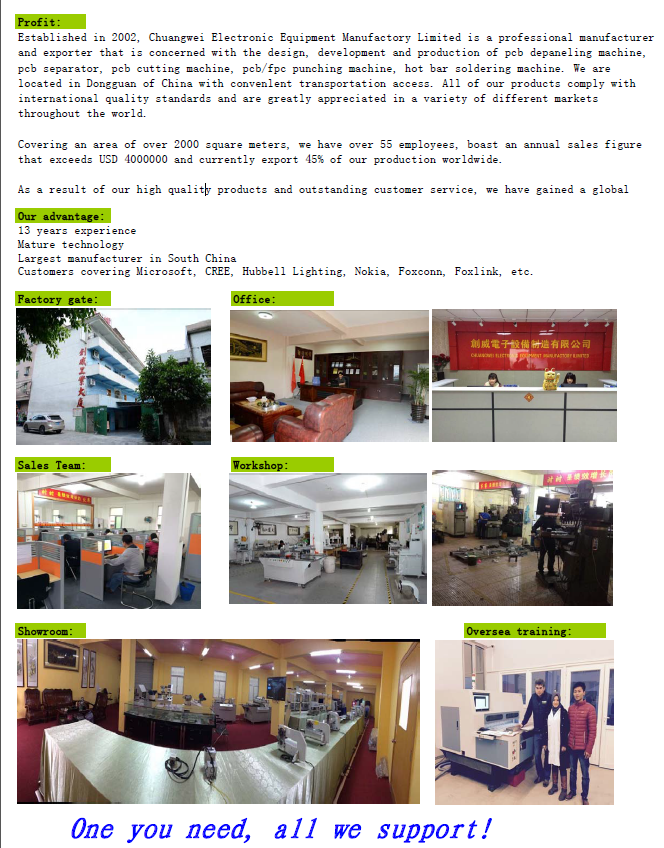

Our production flow