Shenzhen Hansome Technology Co., Ltd. |

|

Verified Suppliers

|

|

Touch Screen Control Single Side PCB Surface Cleaner with Dust Collector

Introduction

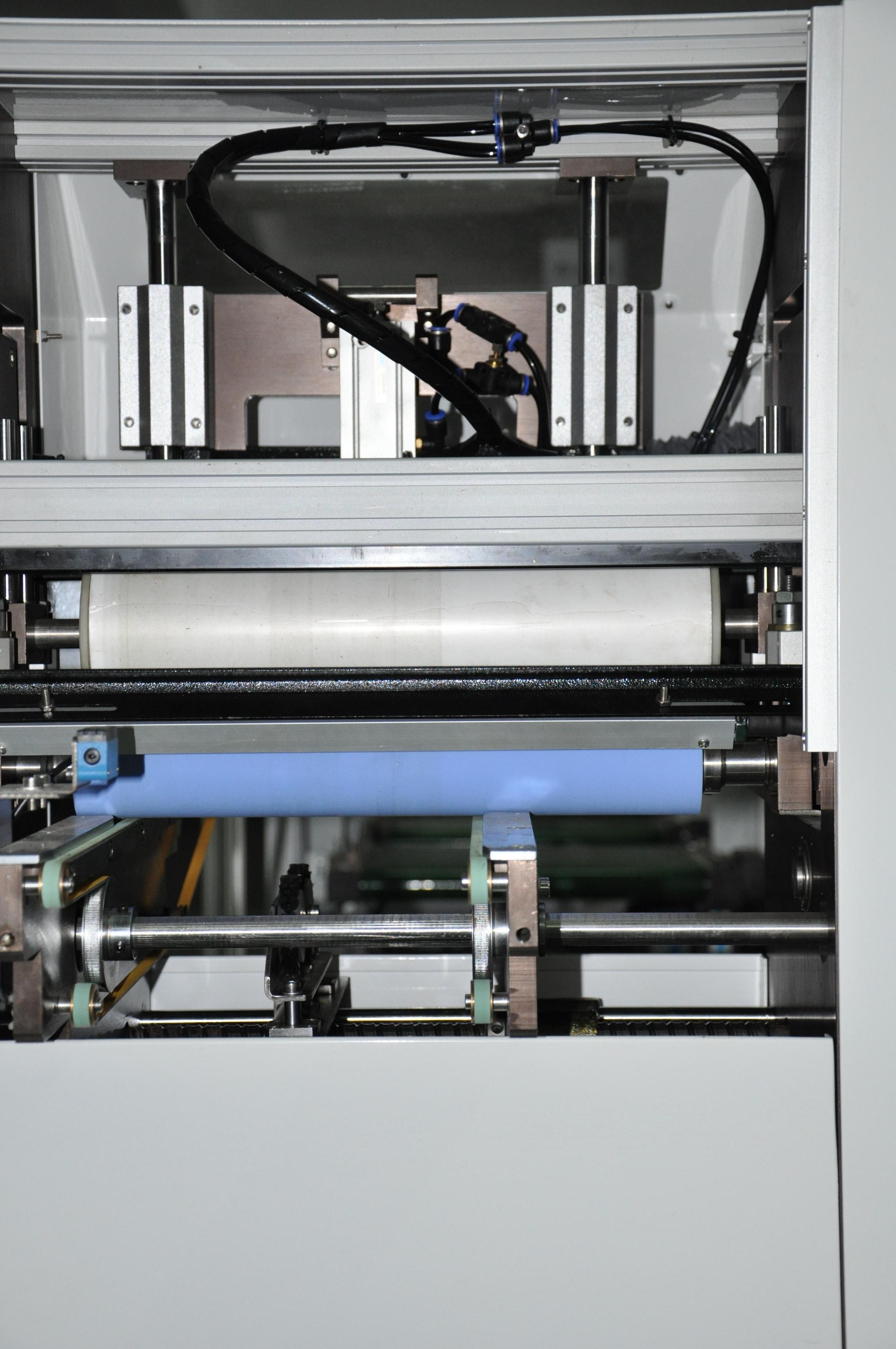

This machine is designed to remove dirty from bare boards before solder paste printing, or other adhesive application. The machine first use a brush to cleaning, then use a ionizer bar to cleaning the static electricity, and after that use a roller together with 2 pcs sticker rollers, at the end also use a ionizer to cleaning the static electricity. The design of the machine will ensure the SMT lines more intelligent at the beginning of the production, it provide a more clean board before PCBA production, make the products more precision and high end.

Specification

| Model | HS-DC250 | HS-DC330 | HS-DC390 | HS-DC460 |

| PCB dimension | (50*50)~(350*250) | (50*50)~(460*330) | (50*50)~(530*390) | (50*50)~(530*460) |

| Machine dimension | 555*820*1350 | 555*900*1350 | 555*960*1350 | 555*1030*1350 |

| Weight | 80kg | 90kg | 100kg | 110kg |

| PCB Transporting height | Standard 900±20mm |

| PCB flow direction | Left to right |

| PCB thickness | 0.4~5mm |

| Power supply | AC100~240V,single phase,300A |

| Air supply | 0.4~0.6Mpa |

| Cleaning brush | 1 pc,ESD,high precision brush |

| Ionizer | 2 pcs(Keyence) |

| Sticker roller | 2 pcs |

| Roller | 1 pc |

| Dust collector | 1 pc |

| Transport speed | 0~9m/min,adjustable |

| Cycle time | Around 8s |

Features

1, The machine produced with a high precision testing, make sure the sticker roller cleaning fully touching the PCB surface.

2, PCB surface cleaning without any interspace.

3, Double ionizer cleaning ensure the static electricity cleaned fully.

4, Ultra-high speed anti-static spiral brush, vacuum extraction clean Method .

5, Special corresponding SMT printing, mount before and after AI

plug-in PCB board on the back of the foreign body clean.

6, Equipped with the static eliminate function, completely

eliminate electrostatic interference.

7, Mechanical parts draw-out design, maintenance is simple.

8, Interface display in English and Chinese, interface operation

convenient and simple.

9, The machine also can used after PCB laser marking.

About Packaging