LIUZHOU ZODE MACHINERY SCI-TECH CO.,LTD. |

|

converting machine paper towel roll wrapper film material

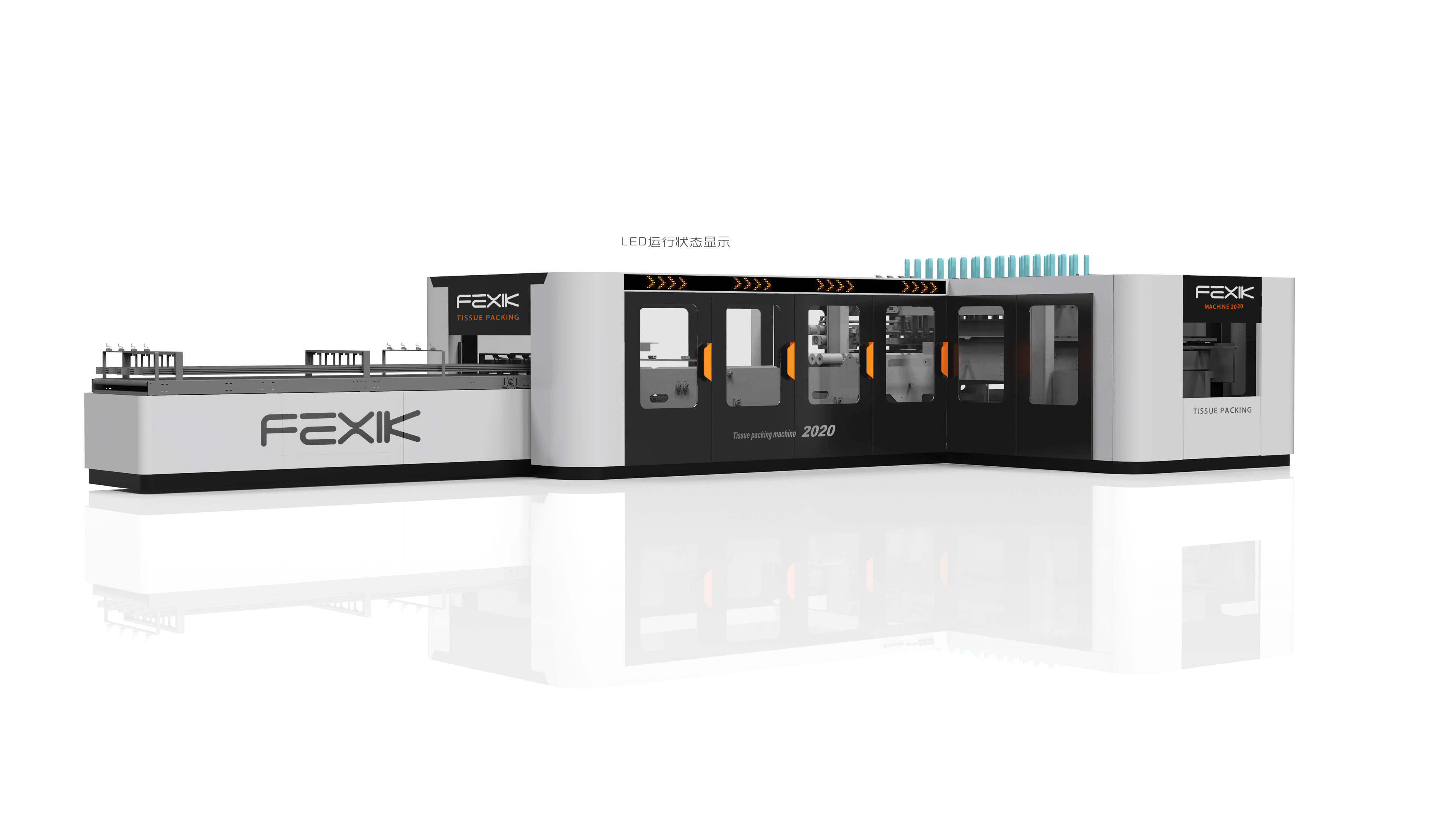

1. Machine Appearance

2. General Description

This paper roll wrapping machine is designed to pack toilet tissue and kitchen towel rolls with a wide range of packing configuration. It is a new generation wrapper with high production speed, popular in many countries. It maintains in perfect shape of the packs when running in a high speed, very stable and high performance.

1) Adopting SIEMENS SIMOTION control system and other advanced

world famous brand components in pneumatic parts, electric parts

and operation parts. Parameters can be set conveniently and quickly

on the touch screen

2)This machine provides various specifications format changeover

between toilet roll and kitchen towel with advanced double layers

arrangement system.

3)This wrapping machine is designed to have quick and flexible

format changeover.

4)This machine is adopted printed film roll as packing material, it

saves the cost.

5) Multiple lanes infeeding and packing function

Samples

4. working principle

The rolls are coming by five channels conveyor; they are launched in the number of lanes according to packaging configuration needed, which is set by HMI, in the single layer or double layers into in-feed section, where they are transported and stacked by group of carbon bars mounted on trimming belts. Carbon bars convey the group of rolls on the elevator, which leads them into the area of folding. The foil positioning section brings the packaging film directly above the rolls by transport belts. The folding process is performed by universal side folders, as well bottom folder and counter folder. Side folding is done by innovative air supported mechanical folders. The overhead pack transport section continuously moves the pack through section of side folding and rotating bottom sealer and deliver pack to side sealing section. All motions and functions are fully controlled by the 21 independent servo motors and 6 inverter motors.

| Name | Technical Parameters |

| Production speed | 35-140 packs/min |

| Max mechanical speed | 160 packs/min |

| Infeed | 1-5 lanes |

| Layers | 1 or 2 layers design |

| Average format changeover time | 10-30 min |

| Roll diameter | 90-160(200)mm(3.5”-6.3”)(7.9”) |

| Roll length | 90-300(3.5”-11.8”) |

| Pack width | 100-650mm(3.9”-25.6”) |

| Pack length | 90-630mm(3.5”-24.8”) |

| Pack height | 90-270mm(300mm) (3.5”-10.6”)(11.8”) |

| Power supply | 380V 50HZ/60HZ |

| Air Consumption | <500 L/Min |

| Wrapping Material | PE,LDPE |

| PE thickness,LDPE | 25-50 microns |

| Real Power consumption | 32KW |

| Machine weight | About 8000kg |

welcome to contact us!