Taikang Yinyu Boiler Manufacturing Co., Ltd |

|

7,000 KW Non Pollution And Fully Automatic Electric Heating Hot Water Boiler

Hot water boiler maintenance:

1. Hot water boilers should pay attention to the following points

during operation:

(1) Do not allow the furnace smoke is burning, because it is easy

to burn the coal-throwing door, look at the fire door and curved

pipe brick and so on.

(2) If the fan vibration, should stop the inspection, generally for

the internal impeller wear, should be replaced.

3. No water should be stored on the ground plane at the bottom of

the hot water boiler to prevent wet corrosion of the base.

2. Hot water boiler situ for 2-3 weeks, should be checked once.

(1) From the upper two holes behind the hot water boiler to remove

the upper ash in the two wing edgy.

(2) Open the front smoke box and rear inspection hole, if there is

ash in the pipe should be removed, such as no ash, can be extended

opening time, once a month, such as still no ash, can be extended

to 2-3 months to open once, at the same time check whether the

smoke box closed tight, pipe end whether leakage, if there should

be timely welding.

(3) Properly check the fan triangle belt, in order to prevent

slipping when running, reduce the wind pressure on the belt wear.

4. Leakage at the interface of valves and pipe flanges should be

repaired.

3. The operation of hot water boiler every 3-6 months, should stop

the furnace for comprehensive inspection and maintenance, in

addition to doing the above 2 work, the following work must be

carried out:

1. Remove the inside of the pot, the water-cooled wall and the

scale and sludge inside the left and right container, and rinse it

with clean water.

(2) Remove the soot and soot from the water wall tube and the fire

surface of the pot.

(3) Check the boiler welding steel plate inside and outside

corrosion phenomenon, if there is a serious defect should be

repaired immediately, if the defect is not serious, can also be

left to the next stop furnace repair, if found suspicious, but does

not affect the safety of production, should make a record, for

future reference.

(4). After the inspection, the boiler paint can be applied on the

fire surface to prevent corrosion.

(5) Check that the rolling shaft of the fan is normal and the wear

level of the impeller and housing.

(6) If necessary, the furnace wall and outer mask shell,

moisturizing layer, etc. removed, in order to thoroughly check, if

found to be seriously damaged parts, must be repaired before

continue to use, at the same time, the inspection results and

repair conditions, filled in the boiler operation register.

4. Hot water boiler long-term maintenance methods: there are dry

and wet method two, stop furnace for more than one month, should

use dry maintenance method, stop furnace less than one month can

use wet maintenance method.

Parameter

CWDR7-95/70

| NO; | Name | Unit | Number | Description |

| 1 | Rated efficiency | MW | 7 | |

| 2 | Water volume | M³ | 14 | |

| 3 | Rated outlet/inlet water temperature | ℃ | 95/70 | |

| 4 | Heating efficiency | % | 99 | |

| 5 | Output/inlet diameter | mm | DN100 | |

| 6 | Design fuels | / | Electric | |

| 7 | Blow down valve diameter | mm | DN100 | |

| 8 | Heating area(room) | ㎡ | 60000 | |

| 9 | Hot water output | M³/h | 18 | |

| 10 | Bulk size | mm | 12000×4000×4600 |

Pre-sale service:

We help customer choose the best boiler model according to

different requirements of various industry. Before delivery we

will provide foundation drawing, layout drawing, boiler room

layout, etc.

In-sale service:

We keep 24 hours online and keep close contacts during the

production process to ensure on time delivery with perfect

finished product.

After-sale service:

1. provide full range of original spare parts.

2. Engineers abroad installation and commissioning service is

available.

3. Our engineers will held a training for boiler workers to

ensure the safe operation.

4. Free maintenance and repair for one year and lifelong

service.

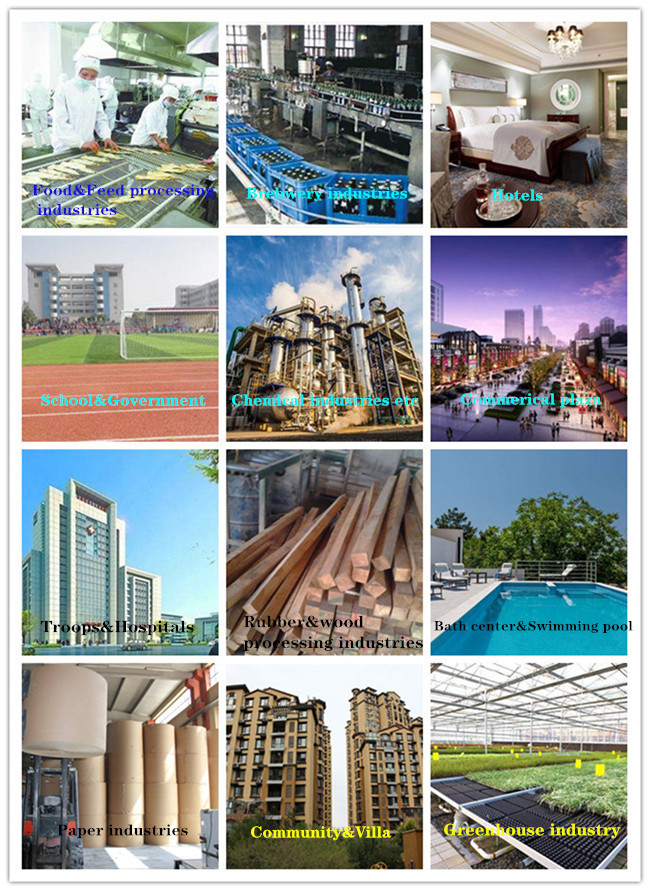

Boiler application areas