NOACH Group Limited |

|

Quick Detail:

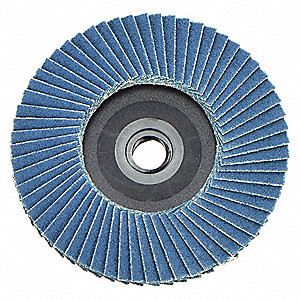

Zirconia Flap Disc Type 27 are Zirconia Flap Disc contains a fiberglass backing plate, and can be used on all types of material from metal to wood. Flat or beveled

Description:

The Flap Disc is a revolutionary hybrid coated abrasive product that combines the stock removal capabilities of a depressed center wheel with the surface finishing characteristics of a resin fiber disc. The result is an abrasive tool that can perform the functions of grinding and finishing simultaneously.

A series of flaps made of abrasive cloth are attached to a semi-rigid fiberglass backing in a fan-like arrangement. As the flaps gradually wear during use, there is a continual supply of "new" grains exposed from the under layers.

Flap discs both grind and finish in one step. Therefore, the traditional two steps process of using a grinding wheel and resin fiver discs is made obsolete. Always go one level coarser with a flap disc as opposed to a resin fiber disc. Zirconia Flap Discs are Zirconia Flap Disc Type 27. Self-sharping Zirconia gain heavy duty structure requires heavier pressure to break down the self-sharpening grains. It is ideal for heavy grinding on ferrous and non-ferrous metals and planning hard woods. This abrasive can last up to 5 times longer than aluminum oxide on tough applications for heavy stock removal to finishing sanding.

Type 27: use for grinding flat surfaces. Most efficient when used at angle 0°~15°

Specifications:

| MID: | 3504-02 |

| Type: | Flap Discs Type 27 |

| Size: | 4 1/2" (115mm) |

| Bond: | Resin over resin |

| Grain: | Zirconia Alumina |

| Grit: | P36~P120 |

| Bore: | 7/8" (22mm) |

Applications:

Weld blending, Grinding, Deburring, Surface finishing and blending, Edge Chamfering, Stock Removal; High-alloy, stainless, and heat-treated steel; high-tensile, non-ferrous metals

Competitive Advantage:

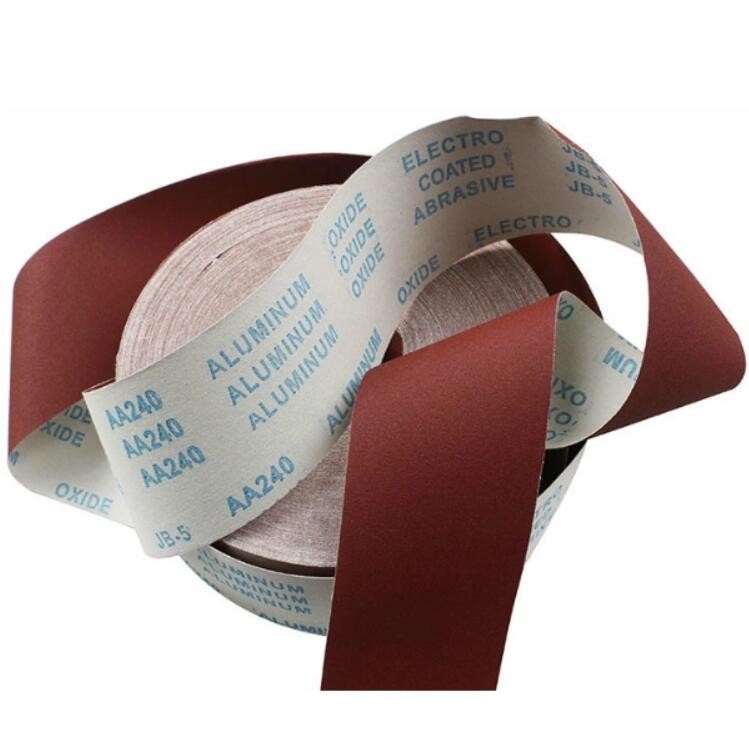

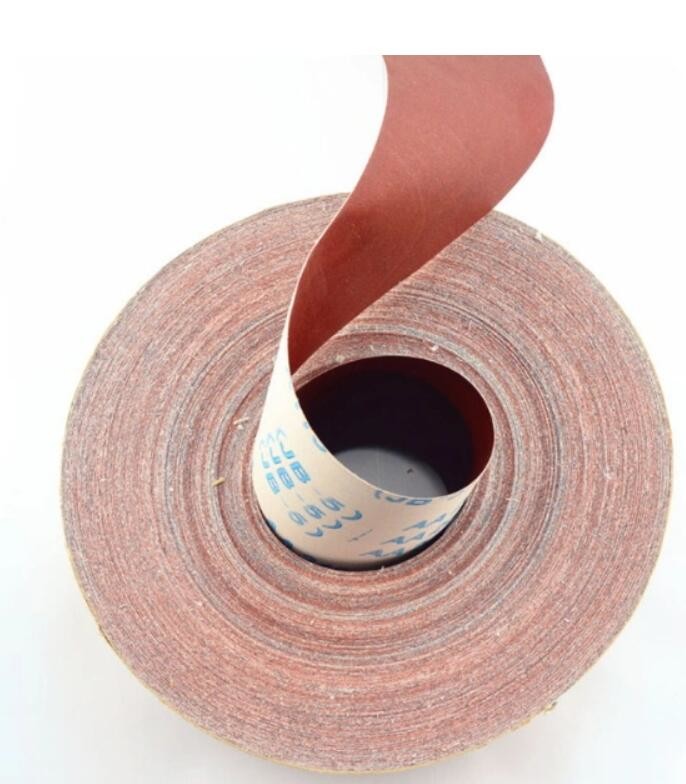

| polishing materials | Abrasive Paper Roll |

| Abrasive products | Abrasive Cloth Roll |

| abrasive materials | Sand Paper |

| polishing products | Amunimum Oxide Sand Paper |

| Sand polishing | Abrasive Sand Paper |

| grain grinding | sandpaper |

| polishing chemicals | abrasive cloth |

| Abrasive Finishing Products | sandpaper roll |

| coated abrasives | sanding disks |

| Abrasive Paper | |

| Abrasive belt | |

| Abrasive stone | |

| Abrasive Discs | |

| Abrasive Rolls | |

| Fibre Discs | |

| Aloxide Cloth Roll | |

| Abrasive Sheets | |

| PSA Abrasive Disc | |

| Sanding Belts | |

| Emery Paper | |

| Abrasive Paper Disc | |

| Coated Abrasive Belts | |

| diamond abrasive products | |

| bonded abrasive products | |

| abrasive brush | |

| abrasive disc | |

| abrasive sheet | |

| abrasive wheels | |

| grinding wheel | |

| Abrasive Jumbo Roll | |

| jumbo abrasive cloth roll | |

| Abrasive Cloth Rolls | |

| Wide Sanding Belts | |

| Segmented belt | |

| Floor Sanding Abrasives | |

| Aluminum Oxide Sanding Belts | |

| Silicon Carbide Sanding Belts | |

| Zirconia Alumina Sanding Belts | |

| Resin Fiber Sanding Discs | |

| Abrasive Flap Discs | |

| Non-woven Abrasives | |

| Sanding Screen | |

| Sandpaper Sheets | |

| Abrasive Paper Rolls |

Performance Level:High Performance

Abrasive Type:Coated

Coated Abrasive Flap Disc Diameter:4-9 Inch

Material Density:Standard

Disc Type (Shape):Type 27 Coated Abrasive Flap Disc

Disc Code:T27

Disc Description:Flat

Disc Backing:Phenolic Fiberglass Backing Plate with 10+1 layer

Grit:60 Grit, also can supply Grit 40#, Grit 120# , Grit 240#,Grit 320#

Configuration:A 60

Grade:common

grinding flap action and smooth running wheels.

The amount of removed metal is reduced,

reducing the heat generated.

Ideal for professional use

Size: 4inch, 4.5inch, 5inch, 7inch.

Grit: P40, P60, P80, P100, P120.

Material: Calcined Aluminum Oxide.

Certificates: ISO9001, MPA.

Blades Quantity: 72pcs, 80pcs, 120pcs.

Sandpaper: Use The Kingcattle Sandpaper.

Package

20pcs/shrink inside box, 200pcs/carton box

More Durable

we use more cloth material and best quality raw cloth material to ensure the using life time .

Higher strength

We use our own tope quality platinum fiberglass backing plate with 10+1 layer to manufacture this Aluminum Oxide abrasive flap disc.

so that it can reach higher speed to meet customers'need.

meanwhile we use double-layer coating technology to ensure the strength of the product.

Lowest price

coated abrasive flap discs are constructed with cloth coated-abrasive material.

cut into squares and glued onto a backing plate.

The main parts of coated abrasive flap disc is the abrasive cloth and backing plate.

the cost price of flap disc depend on these two items.

We have our own fiber glass backing plate production line to meet our flap disc manufacture.

reduce our flap disc cost during the manufacture process.

Flap discs and wheels are suitable for:

- Grinding and finishing of welds

- Deburring, rust removal and snagging

- Suitable for most ferrous & non-ferrous materials

- Excellent for surface finishing

CGW Flap Disc specifications and applications:

Aluminum oxide coated, for alloy steel and low-alloy steel

Zirconia Alumina coated, for high-alloy, stainless, and heat-treated steel; high-tensile, non-ferrous metals

Flap discs S/CSilicon Carbide coated, for marble, stone, glass, and non-ferrous

metals

CGW Flap Discs are available in the following sizes:

100mm X 16mm (4" x 5/8")

115mm X 22mm (4-1/2" x 7/8")

125mm X 22mm (5" x 7/8")

150mm X 22mm (6" x 7/8")

180mm X 22mm (7" x 7/8")

Three common tool categories are used for surface preparation and cleaning in welding applications:

What you should choose depends on the requirements of the application and, of course, your personal preference.

Abrasive products and wire brushes differ in their performance and purpose. Abrasive products are designed to remove base material, whereas wire brushes are not. When surface preparation or weld cleaning requires that you remove slag or mill scale, a wire brush is generally recommended. Note, heavy mill scale sometimes can be too much for even the most aggressive wire brush. In these instances, choose an abrasive product. Abrasive products are specifically designed for applications such as stock removal, edge beveling, chamfering, and weld grinding and blending. Conversely, if an application requires that you preserve the base material during surface preparation and weld cleaning, a wire brush is still your best choice. Here’s how these products work.

Bonded Abrasives/Grinding Wheels. A combination of the grain type, grain size, and bonding agents (resins and additive fillers) determines the performance of each. Bonded abrasives are generally more aggressive and remove material faster, requiring a skilled operator who knows how to prevent damage, gouging, and undercutting. Wheels are constructed of abrasive grains, including aluminum oxide, silicon carbide, zirconia alumina, ceramic alumina, and combinations of these grains. A resinoid (organic) bonding agent is mixed with the abrasive grains. Finally, this mix is molded and combined with fiberglass reinforcement layers for durability and strength.

Aluminum oxide (AO) wheels are the most popular and are good for many general-purpose applications. Products made with a combination of ceramic and zirconia alumina cost more, but typically provide a better overall life and material removal. They are a good choice for materials such as armored steel, structural steel, cast iron, and INCONEL® alloys.

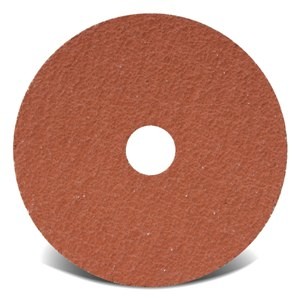

Coated Abrasives/Flap Discs. These items are constructed using the same grain types as those found in bonded abrasives. Coated abrasives bond the abrasive grains to a backing cloth, which is most commonly cotton, polyester, or blended backing rather than the hard grinding wheel found on bonded abrasives. This abrasive cloth can be cut into smaller flaps and layered radially to form a flap disc. It is this layered construction that gives flap discs a much softer, more forgiving feel.

The flaps are designed and positioned to wear away as the grains deplete, exposing new, fresh, and sharp grain underneath. Flap discs are often more comfortable to use and offer the aggressive cutting and grinding action of a grinding wheel; however, they also allow for blending and finishing work, which is important when the material needs to be painted, primed, or powder-coated.

Wire Brushes and Wheels. These are the primary choice for weld cleaning, when it is necessary to remove spatter and other contaminants prior to finish or the next weld pass. Remember, the tips of wire brushes do the work, functioning like tiny hammers hitting and preparing the work surface. Applying the appropriate pressure is critical to power brush performance, as excessive pressure flexes and bends the wires, preventing the tips from working. This can lead to premature wire breakage and dramatically reduce brush life.